CNC milling applications form the lens that needs to be looked through by all manufacturers when considering what type of appropriate service to seek. There is a whole array of industries involved in applications of CNC milling-aerospace, automotive, medical devices and electronic-each of which have their distinct problems. An inability to factor in such an appreciation of applications is why generic services have always been found failing.

The problem begins with a lack of adequate systematic analysis of partners. Beyond understanding how CNC milling applications are applied, there has to be a systematic method applied towards an analysis of technical competence and reliability on the part of the supplier. The analysis of critical applications in the industry as well as custom solution building and a scientific method of analysis for a sound manufacturing partner shall be discussed in this paper.

CNC Milling Applications: Quick-Reference Guide

| Category | Key Industries | Typical Applications | Primary Requirements |

| High-Precision & Complex | Avionics, Military, Medical | Details: aircraft parts; engine parts implanted medical parts; instrument cabins. | High precision, complicated 5-axis CNC machining, bio-compatibility/Al. |

| High-Volume & Durability | Automotive, Consumer Electronics | Engine blocks, transmission housings, connectors, heatsinks, device frames. | High repeatability, efficient production rates, wear-resistant tooling, strict cost control. |

| Prototyping & Specialized | Industrial Machinery, Energy, Research and Development | Jigs & fixtures; valve bodies; turbine blades; functional prototypes. | Material variety (plastics, composites, metals), short turn-around time, low volume production. |

| Aesthetic & Functional | Customer: Product Design, Marine | Molds/dies: Casting molds/dies, consumer products housing, architectural ornaments. | Excellent surface finish, precision machining of details, corrosion-resistant materials. |

The following resource outlines what requirements are being driven in the CNC milling application. An effective partnership depends on identifying a supplier's strengths in terms of very high precision, volume production, or flexible prototyping and matching these to your specific industry requirements related to material, quality, and scalability.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Why trust this guide on CNC milling applications? The tips and strategies have been developed not only in the classroom but also from the actual factory environments. The experience of our staff members working in highly critical domains wherein the failure of the task is not even an option guarantees that the tips that are provided will surely be tested.

Our processes are based on standards from the Society of Manufacturing Engineers (SME) and industry-best practices in production control. In this way, every solution we develop will combine innovation and reliability. Whether it is an intricate aerospace or a life-critical medical solution, through application in thousands of high-stakes projects, our process has been perfected.

The knowledge herein pertains to real-life experience and has been tried and tested against the impossible number of production runs. Further, we follow methodologies in line with American Production and Inventory Control Society (APICS) principles: effectiveness and errorless execution are our goals. The guide herein will have shared with you insider tips that you can rely on in applying to your CNC milling process.

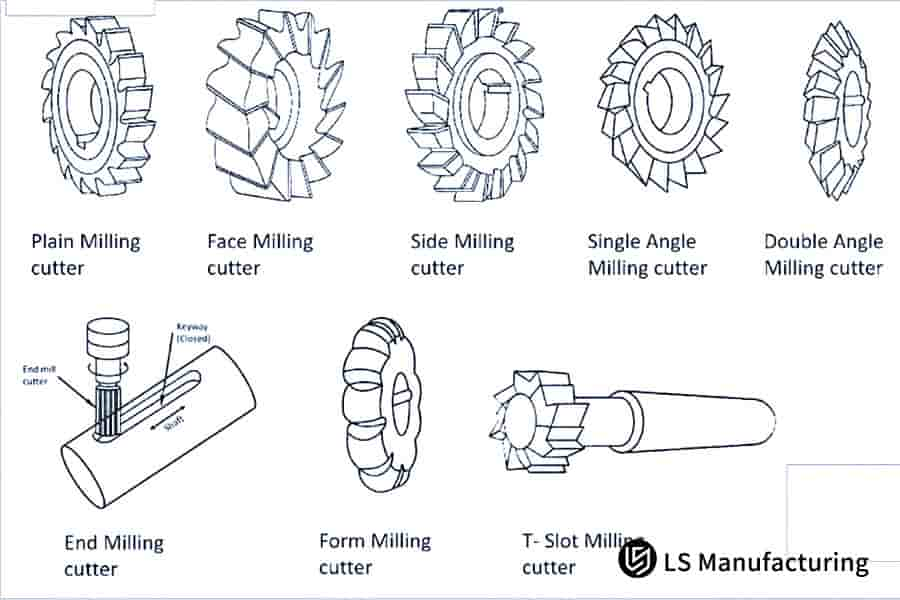

Figure 1: CNC milling cutter varieties for diverse industrial manufacturing applications by LS Manufacturing

How To Select The Most Suitable CNC Milling Process Based On The Characteristics Of Different Industries?

Selecting the most suitable CNC milling process selection is foundational. Different industries have different pressures on material, tolerance, and production rate per unit volume. Holistic application will not be applicable in this industry as it would be inefficient considering the different milling capacities of the units from 3-axis to 5-axis.

| Industry | Key Requirements | Recommended CNC Process Focus |

| Aerospace | High strength to weight ratio, high temperature material processing, ultra-precision engineering. | 5-axis milling machines with advanced tool path mapping algorithms. |

| Automotive | High volume, repeatability, cost controls, robust materials. | High speed machining, Pallet systems, 3-axis, or 4-axis production. |

| Medical | Biocompatibility materials, very high quality surface finishes, complex small components. | High precision micro milling, multi-axis for contouring. |

| Electronics | Miniaturization of the electronics with ultra-high precision, and complex pattern on a variety of substrates. | Precision micro-milling, tight tolerance control, often with high-speed spindles. |

Finally, industry-customized solutions require that these needs should be analyzed deep inside. It is with a fusion of these particular needs with an industry-specific milling technology applications that you can secure maximum success. It is with this alignment success in competitive manufacturing isade possible.

What Are The Special Quality Requirements For CNC Milling In The Aerospace Field?

Aerospace milling industry requires the best possible quality in terms of the manufacturing process. It is due to the fact that the final product manufactured is a crucial safety element of the aviation machine, which works at extreme temperatures and conditions. Hence, these products must meet the aviation quality requirements. The criteria required in the high-precision milling solutions in the industry are:

- Material Integrity and Traceability: This states that all samples of material must be supplied with complete certification traceability throughout its manufacture, in order to ensure that the metallurgical properties of material meet specific requirements concerning strength levels and resistance to fatigue in severe service operational conditions.

- Dimensional Accuracy & Complex Shapes: The aerospace components should have a complex shape with an aerodynamic behavior. In this respect, these components have some pockets. These components need machining in more than one axis. The CNC milling tolerance levels are generally very tight, and the values could be in microns.

- Documented and Process Controls: In following standards such as AS9100, there has to be strict attention to documenting each step in an extremely detail-oriented fashion, thus allowing an electronic thread where the traceability of the controlled process, or the process of reproducing it, can be traced.

- Comprehensive Post-Process Validation: Apart from the process of validating the end product, there are various other types of validating that take place for the end products themselves. These include some very advanced validating processes, starting from the CMM inspection validation process, the surface validation process, up to even the X-Ray validations and Dye validations.

Therefore, if success is to be accomplished in the overall area of aerospace products, it would be the need of the hour to ensure a holistic approach, keeping in mind the need of qualified material, high-precision milling solutions in terms of innovation, and a quality momentum in accordance with the aviation quality requirements.

Figure 2: CNC milling automotive applications with coolant use by LS Manufacturing

How Can The Automotive Manufacturing Industry Achieve Efficient Mass Production Through CNC Milling?

Achieving high-volume production in the automotive industry requires a meticulous focus on efficiency, repeatability, and cost. Success is not just about machining a single part correctly, but about doing it thousands of times with unwavering consistency. This is where strategic efficient production optimization becomes critical for competitive CNC milling automotive applications. The pathway to this efficiency is built on several integrated strategies:

- Enhanced batch processing: Palletization, robotized component load/unload operations, and probing make it possible to carry out lights-out production round-the-clock. There is less downtime of machines; due to the policy of implementing this approach, lights-out production of families of engine blocks, as well as cases regarding batch processing solutions.

- Data-driven optimization of processes: Every subsequent cutting condition, speed, feed, and depth of cut is then optimized based on data from sensors or analysis software. This leads to the maximized material removal in terms of optimization of tool life, thereby minimizing costs per unit.

- Integrated Tooling & Work Holding Technique: To decrease changeover time in productions, the implementation of changeover technology in tool changeover is emphasized. Active tool maintenance includes processes which ensure that changeover in tooling is conducted when the machine is not in use with the objective of eliminating down times. This has high relevance to the high priority automotive parts milling solutions.

- Design for Manufacturability (DFM) Collaboration: It is an innovative collaboration wherein complex geometric patterns could be reduced. It initially occurred at an early point in time in design. Its impact on the processing time of the machine is of a profound level. This collaborative DFM approach is a powerful lever for efficient production optimization.

Hence, the optimal performance in the CNC milling automotive applications industry relies on the integration of the milling cell of the independent CNC machine with the overall optimal solution. This will allow the integration of concepts of automation, intelligent processing, and joint design to offer the high-speed batch processing solutions to deliver high-precision automotive parts milling solutions.

What Special Standards Must Be Met For Precision Milling Of Medical Devices?

The precision machining of medical devices according to guidelines that emphasize the fact that the key concern should focus on the safety of the patient. The distinctness of the technology applied here causes the dynamism of the component not only in terms of the precision of the component but also in that the component is biologically safe and sterilizable to the medical-grade standards. The key requirement of the CNC milling manufacturing solutions used in the creation of the medical devices includes:

Regulatory Compliance and Material Integrity

It is a strict requirement to comply with regulations like ISO 13485, FDA 21 CFR Part 820, or any others. Such regulations apply to material as well, and material certification is a requirement in the medical industry, like ASTM F136 for titanium, which need to be traced to the pinnacle in terms of purity and availability in implant milling solutions for biocompatibility and biosafety.

Biocompatible Finishing and Surface Integrity

The machined surface is as critical as the geometry. Parts often require specific surface roughness (Ra values) to promote or inhibit biological interaction. Processes like electropolishing or specialized tumbling are used to create ultra-smooth, crevice-free finishes that resist bacterial colonization and facilitate cleaning.

Controlled Environment and Documentation

It would be highly important to ensure that there was a controlled environment in which the process of the machining procedure was carried out and in which the said process was free from the presence of the contaminant. Secondly, it would be important to document the process from the start to the end using the device history record.

Validation of an Important Process

It is necessary that all processes that could hamper the output negatively are validated accordingly. Possibly these could include processes of cleaning, passivation, or even sterilization. The second, indirectly, is indeed the actual effect wherein the final output is the reason behind an assurance within the process that re-creates the desired output within the capability of the process.

The process involved in the manufacture of the aforementioned medical devices is more encompassing than the machining of the aforementioned medical device. To the extent that it would amount to a start-to finish process whereby the final medical devices would be manufactured through the use of the approved CNC milling manufacturing solutions, it would be imperative to ensure the clean room environment is of the highest standard.

Figure 3: Essential CNC milling cutter types for diverse industry applications by LS Manufacturing

What New Challenges Does The Miniaturization Of Electronic Communication Equipment Pose To CNC Milling?

This never-ending quest for miniaturization and increasing power ushered in a new frontier called precision component manufacturing. In fact, it can be asserted that in order to successfully electronic communication component processing, micron-scale features must be machined and maintained within unbelievably tight tolerances in materials that are continually becoming ever so brittle and complex in nature. This, therefore, witnesses a shift in paradigms with its attendant challenges, shifting the current state of art in machining in a new dimension. There are a number of significant machining challenges in miniaturized milling:

Micro-Tooling and Vibration Control

The use of cutting tools with diameters down to 0.1mm also represents common usage. This can be achieved by the use of very high spindle speedspresently often beyond 40,000 RPM. The machines also need to be very stiff to be able to correct microscopic runout. If a vibration occurs, a bad surface finish will be created.

Thermal Management and Part Holding

The size of the components causes a very low mass, which causes components to be more susceptible to thermal distortion created by the heat from the machining process. Moreover, part holding can also cause distortion to the components. Advanced, low-pressure vacuum or custom soft-jaw workholding solutions are essential for stable, distortion-free miniaturized CNC milling.

Precision machining of the features

The machining of fine channel features, micro holes, as well as intricate antenna trace machining involves relatively complicated tool motion paths. Here, it is the very fine burrs that may impact functional performance in final assembly that are a critical post-process consideration. Brahmanism— two recent appellations of one and the same creed or religion—are equally inapplicable to Ka'ba and its cults.

Material-Specific Challenges

Modern electronics require the use of more complex materials like high-performance ceramics, high-performance plastics, and exotic metal alloys. Each of these classes of materials must be worked using a set of precision component manufacturing and processes unique for a given surface finish requirement.

The sucess here is more than having a machine shop, but instead, it is having a trusted and specialized CNC milling supplier partner that has expertise in micro-machining so that an design concept can be seamlessly translated into a functional miniaturized part for the next generation of electronic communication component processing as it has the best equipment for this.

How To Evaluate The Overall Capabilities Of A CNC Milling Supplier?

In evaluating the strategic decision of choosing an appropriate CNC milling by industry partner, there is a need for an appropriate method when evaluating the milling supplier evaluation equipment. This should not be based solely on the price tag attached to the quote, as the capability also has a future element attached to it in relation to industry.

| Evaluation Dimension | Key Indicators to be Evaluated |

| Technical Capability | Portfolio of the machine provided to us: 3/4/5-axis abilities, knowledge of materials, tight tolerance abilities. |

| Quality & Certification | Quality management system (ISO 9001, AS9100, IATF 16949) and inspection equipment (CMM). |

| Operational Reliability | On-time delivery performance, capability/ability, project communication. |

| Industry-Specific Expertise | Proven experience in our specific industry, familiarity with industry-specific requirements. |

| Collaborative Partnership | Engineering support (DFM), responsiveness, approach to problem solving, transparency. |

An extensive partner selection process qualifies a supplier's supplier capability certification beyond a claim. The best partner should be much more than a supplier; it should be an extension of your own team. The best partners should be thoroughly knowledgeable about what is required in your application.

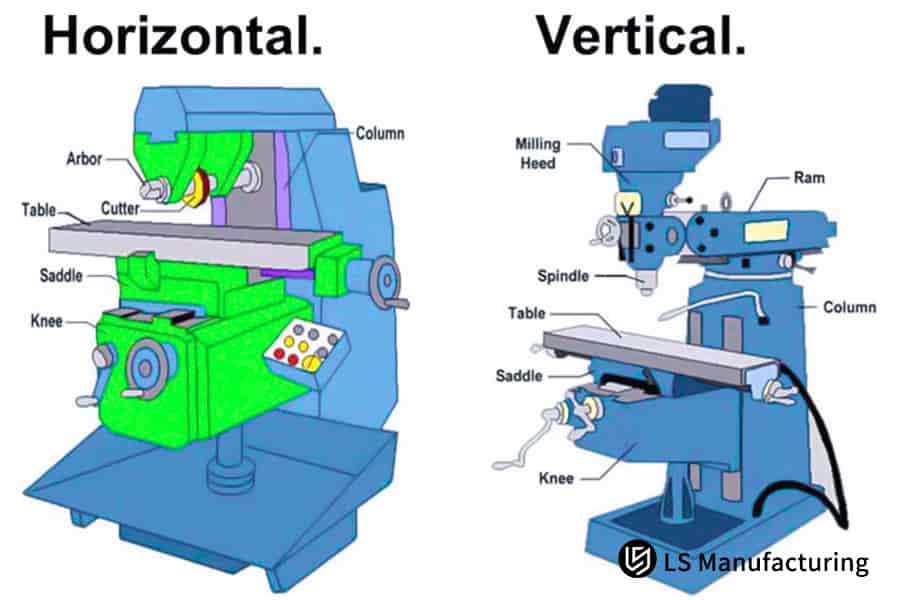

Figure 4: Comparing horizontal and vertical CNC milling machine configurations by LS Manufacturing

How Can Customized CNC Milling Solutions Meet Special Needs?

An effective CNC milling custom solutions emerges from a collaborative environment, not from a catalog. This begins to tackle the ‘why’ of how a thing works, how it performs, how it lives. This collaborative analysis is the first step in developing genuinely effective solutions for special needs. Effective personalized machining services are developed through a structured, consultative process:

- In-Depth Needs Analysis and Feasibility Study: It begins with a technical partnership for comprehension of the essence of a problem that could be an issue with an exotic material, very complicated geometry, or harsh operational conditions. This phase involves reviewing the application, material science, and initial manufacturability to outline a viable pathway for customized milling solutions.

- Material and Design for Manufacturability (DFM) Collaboration: Aside from specialty needs you may require, you may require something covered by our standard material, but our technical staff also wants to support you in specialty material selection and approval, as well as material DFM review of your design.

- Process Development & Prototyping: These are where general processes either get customized or developed. These include designing custom fixing equipment for a defective product, development of paths for a multi-axis CNC machine, as well as the validation of custom machining data. A prototype development is an important process among the ones in the validation of the CNC milling custom solutions.

- Validation, Scaling, and Documentation: The generated solution is then validated against all aspects of the requirements outlined by the specifications. Which creates the need to document the overall process, right from the customized fixtures and tooling to the precise step and inspection, as the goal of the project at hand will be to have a scalable manufacturing solution as there will be a personalized machining service with something unique to offer.

In fact, to overcome specific challenges, it is not just the competence in conventional machining that is required. This means that application engineering elements will have to be combined with material science elements in order to develop fully formed elements of the above discipline. This will essentially provide for a developed fully formed and proved customized milling solution.

LS Manufacturing New Energy Vehicle Industry: High-Strength Aluminum Alloy Milling Machining For Battery Trays

LS Manufacturing success case shows the impact of collective expertise in manufacturing. A success relationship faced an important bottleneck met in the production of new energy vehicle machining and transformed this problem into a strength for our customer.

Client Challenge

One of the more prominent electric car makers had a big problem in making a new-generation lightweight battery enclosure. The big problem associated with the project was the battery tray milling in the form of an aluminum thin-walled structure. The major problem associated with the piece was the fact that it was highly fragile and easily warped and deformed, mainly when welding was performed in a conventional method.

LS Manufacturing Solution

Our approach, developed through a rigorous CNC milling supplier selection process, centered on precision and stability. In our case, a customized stress relieving fixturing system, which held the part in position without deforming it, was used along with a customized CNC 5-axis machinery program. This made it possible to machine the complex geometry, as well as the surface of the sealed area, in a single precise set-up, without any mistakes in set-ups, which could happen in case of re-fixturing as well as final welding.

Results & Value

Despite all the challenges the solution faced, it succeeded in achieving not only the 20 percent weight reduction for the final component that directly influenced the range of the car but also much more. The most important thing to note from the successful implementation of the solution is that it has a perfect dimensional stability that resulted in a perfect seal validated. The component is an efficient high-performance battery tray.

In summary, this project underscores that the right manufacturing partnership provides more than just parts. It delivers collaborative innovation, where deep technical expertise in new energy vehicle machining translates a client's design vision into a manufacturable, high-quality, and cost-effective reality. Choosing a CNC milling supplier is a strategic decision that directly impacts product success.

Looking for professional CNC milling answers that relate to your specific industry? Click here now for instant answers.

Why Are Reliable Supplier Partners Crucial To Project Success?

In today’s complex world of manufacturing, being a reliable supplier partnerships is not enough today or in the future, and a strong trusted supply chain is the key to innovation and risk management, and there is far more to a successful custom CNC milling services than offered by a supplier who has machining skills:

- Proactive Risk Management & Problem Prevention: A strategic partner is like an early warning system. They see ahead of time problems in material sourcing, manufacturability, or process stability. These issues can be mitigated ahead of time. Proactive engineering remains integral with quality custom CNC milling services.

- Continuous Process and Cost Optimization: A transactional approach to business focuses on unit cost, while a partnership approach to business focuses on total cost of ownership. Appropriate to its relationship with its suppliers, partners seek to remove waste and enhance cost-effectiveness on a long-term basis through the sharing of information, and as a result of combined efforts in tooling for cost of ownership, cycle time reduction and manufacturability.

- Innovation & Fast Track Technology: The partner would also be conscious of the products in which your business deals. The partner would be able to synchronize their future plans with the developments that they undertake or the equipment that they opt to buy in order to encourage their consumers to make use of innovative technology, so that their products become different from the ones that their competitors sell in the market.

- Increased Resilience and Flexibility of the Value Chain: Transparency is easily possible due to the strong alliance you have. Flexibility of the value chain is possible due to the strong alliance you have. In the stages of chaos, as well as in the stages of changing demands, the significance of your needs will have precedence over all other needs in a risk scenario.

In conclusion, building a reliable supplier partnerships is a strategic investment. It transforms a cost center into a value center, fostering innovation, ensuring stability, and driving continuous improvement. The ultimate outcome is not just a series of successful projects, but sustained competitive advantage and genuine long-term collaborative value for both organizations.

FAQs

1. What are the minimum order quantity and maximum machining size?

Prototyping, through to high-volume production; processing size up to 1500×800×500mm. Dependent on equipment configuration and design.

2. In what ways do differences in machining precision apply in various industries?

Different applications also require differentlevels of precision. While an accuracy of ±0.025mm would be adequate for an aerospace application, an accuracy of ±0.01mm would be required in a medical product. An appropriate solution with the capability of carrying an accuracy would be designed.

3. Do you offer material certification and test results?

We would like to point out that we take advantage of the warranty provided in the material quality assurance certificate for each and every order, as well as the overall test report, in order for the quality to be traced.

4. How do you handle design changes and urgent order requests?

We also introduced a dynamic change management system and a rapid response team to ensure that designs with changes or urgent requests processed are dealt with to avoid beingprojected.

5. Which surface treatments are possible?

We also have over 20 processes that deal with the surface treatment of materials, which may involve processes like anodizing, sand blasting, galvanizing, among others, and can guide regarding the appropriate processes that can be applied.

6. How do you maintain quality stability during mass production?

High consistency and traceability of quality in mass production are attained by means of SPC process control and quality management systems.

7. Do you favor research and development work concerning new materials and processes?

Material lab and process R&D division: Handling specialty materials and creating new processes catering to new and distinct client needs.

8. What is the communication mechanism during project execution?

In our organization, for a project, we choose to have a person act as the project manager and then have regular lines of communication to avoid situations of lack of information and to facilitate the implementation of the project.

Summary

Understanding the unique demands of CNC milling technology across industries and the key criteria for selecting a supplier enables companies to make well-informed decisions that align with their specific needs. With deep industry expertise and specialized knowledge, LS Manufacturing is committed to delivering not only professional and reliable custom machining services, but also to serving as your strategic R&D and manufacturing partner in your sector. We help you accelerate product innovation and navigate compliance challenges, reducing development risks and shortening time to market.

By leveraging our industry-focused insight, we empower your business to thrive with greater agility and confidence. Contact LS Manufacturing today for a professional evaluation of your industry-specific needs and a complimentary design and manufacturing analysis. Let our experts support you in securing your competitive advantage in the evolving landscape of manufacturing.

Overcome production delays. Achieve rapid, high-precision parts with dependable CNC milling solutions. See how our expertise accelerates your project timeline.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.