Wood CNC turning operations face significant cost control challenges in the manufacturing process. The problem arises basically because of the utilization of the wrong tools. Consequently, a chain of events is set in motion at the same time, such that the inappropriate machining parameters for the wood product manufacturing process result in the possibility that the produced wood product potentially endangers the surface finish of the wood product. The wood tools might tend to wear out.

However, the core problem, which arises from the mentioned issue, originates from the lack of knowledge of systematic wood turning tool selection. It has been observed that most of the business organizations resort to the temporary methodof problem-solving, rather than using the scientific method of problem-solving. They lack sufficient knowledge to relate the critical properties of wood, such as hardness, grain direction, moisture content, and resin, to the properties of the tool, including materials, geometry, and coating.

Wood CNC Turning Quick Reference Guide

| Category | Key Parameters | Recommended Values | Cost Impact |

| Tool Selection | Type of material, shape of cutter, coating | HSS for soft wood, carbide for hard wood | High-quality tools reduce long-term costs |

| Cutting Speed | RPM range | 400-600 RPM for hardwood, 600-1000 | Optimal speed reduces tool wear and energy |

| Feed Rate | Step-down depth | 0.5-1mm for hardwoods | Proper feed prevents tool breakage |

| Tool Geometry | Rake angle, edge type | Sharp cutting edge with appropriate rake | Geometry affects chip removal and finish |

| Material Choice | Wood hardness, grain | Standardized materials, easy-to-process types | Material cost + processing difficulty |

| Production Strategy | Batch size, standardization | Mass production, standardized components | Economies of scale reduce per-unit cost |

| Maintenance | Tool inspection, spindle care | Regular cleaning, lubrication, calibration | Preventive maintenance reduces downtime |

Wood CNC turning machines are also dependent upon efficient tool management, effective conditions for operation, and maintenance. Proper use and operation techniques will be effective in reducing costs. Quality tools will also bring down costs despite the cost of such superior tools.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Up until now, with our experience with wood CNC turning, we not only are theorists but also implementers of our theories. In fact, our shop was a testing ground where we ourselves were able to learn and understand the complexity of direction, moisture content, and geometry of wood. Our standards for processing are already aligned with specific standards from Additive Manufacturing (AM).

Our own hands-on experience is unparalleled, and we have optimized thousands of custom wooden parts, whether very intricately detailed wooden furniture or true functional wooden spindles in architectural components. And each one of these, in its own right, has given us experience in how to reach a certain balance between speed, tool durability, and finish in optimized processes not unlike 3D Systems' process optimizations.

By following this tutorial, you are tapping into knowledge that has been tested in the battlefield of our workshop. Every single recommendation about tool choice, feed rate, or finishing has been explored on our equipment. What is passed on here is not theoretical acrobatics but a system of thought applied day in and day out to keep all wood passing through here accurate, long-lasting, and inexpensive.

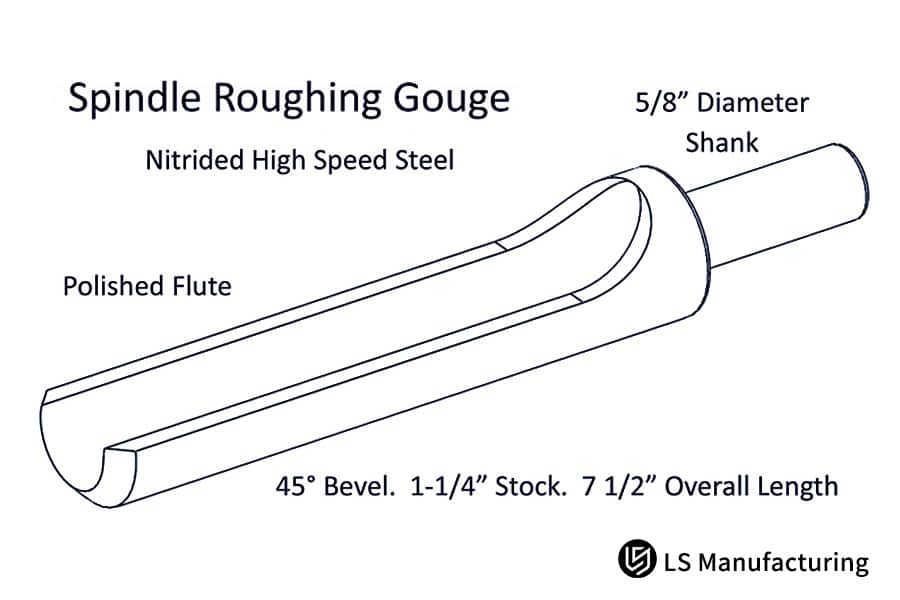

Figure 1: Necessary tools and dimensions for computerized wood lathe work by LS Manufacturing

How Does Tool Selection Affect Overall Cost-Effectiveness In Woodworking CNC Turning?

In wood CNC turning operations, strategic tool selection directly influences overall cost-effectiveness through multiple performance dimensions. On this subject, it should be pointed out that the use of the right tools in the wood CNC turning process is the main factor responsible for the efficiencies achieved in the turning process as well as the tool life resulting from the same.

| Impact Area | Key Factors | Cost Benefit |

| Machining Efficiency | Cutting speed, feed rate, material removal rate | Up to 25% cycle time reduction |

| Tool Life | Tool material, coating, geometry | 30-40% reduced tooling cost |

| Surface Quality | Surface finish, secondary processing | Lower cost of sanding and finishing |

| Material Compatibility | Hardwood vs. softwood tools | Lower scrap rates and rework |

| Production Consistency | Dimensional accuracy, repeatability | Minimized material waste |

| Energy Consumption | Power requirements, cutting forces | Lower energy costs |

| Total Cost of Ownership | Purchase price + operational costs | Better long-term ROI |

Strategic tool selection in wood CNC turning delivers significant cost-effectiveness improvements across multiple dimensions. In this way, it improves the efficiency, the lifespan of the tool, and the quality of the output for maximum profitability in the production of the wood pieces. On this account, it may be justified for strategy implementation concerning the CNC turning of the wood.

How To Optimize CNC Woodworking Turning Costs Through Scientific Tool Selection?

Price shopping cannot be effectively used for CNC wood turning cost. A scientific tool selection for a raw data set is required to translate into savings with a proper set of items for a production life cycle approach.

Data-Driven Tool Performance Analysis

The first step in performing scientific tool selection is based on the idea of broad testing and data collection. Through use of comparison of tool geometric properties, coating, or materials with wood properties or part size, a balance between cost and performance is achieved for optimal enhancement of the choice regarding cost-effective aspects of the CNC wood turning process.

Application-Specific Optimization Framework

A prerequisite for any optimization strategy will be to study many variables simultaneously. The wood hardness, wood finish, scale of production, or the wood part geometry, which makes the wood part difficult to turn, will determine the most appropriate cutting tool that will be applied based on the considerations to be made using the decision matrix.

Lifecycle Cost Modeling and Validation

There must be prior identification regarding the scientific tool selection, implying that cost of ownership versus cost of acquisition is to be considered. These cover cost during lifecycles, replacement cycle cost, unproductive time cost, and the scrap rate. Use cases developed on this principle helped validate a reduction in costs of 20-35% per unit and continued to demonstrate the effectiveness of data optimization strategy for managing CNC wood turning cost.

It can be concluded that, in order to ensure that the CNC wood turning cost is manageable, a systematic approach using scientific tool selection involves applying knowledge, analysis, and models to maximize achievements to have greater opportunities of efficiency with reduced cost. This comprehensive optimization strategy delivers measurable savings while maintaining production quality and reliability, proving that smart tooling decisions are a powerful driver of manufacturing competitiveness.

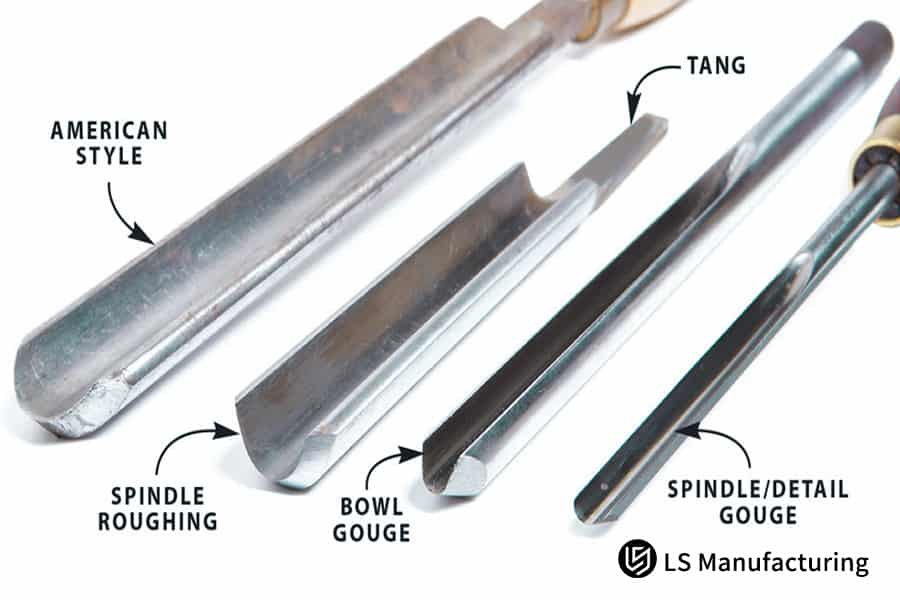

Figure 2: Optimal gouge specs for economical CNC wood turning by LS Manufacturing

Key Tools In Woodworking Lathe Machining: Performance And Applications?

Understanding the performance characteristics of essential wood lathe turning tools is crucial for selecting the right tool for each application scenario. Every tool has capacities that make them fit for certain tasks on the wood.

| Tool Type | Performance Characteristics | Application Scenarios |

| Roughing Gouge | Wide U-shaped flute; heavy removal of material; medium speeds (800-1200 RPM) | Making first spindle blanks, knocking off corners in square materials |

| Spindle Gouge | Bevel edge on ground, shallow flutes, regulation of cutting action | Creating beads, coves, and detailed spindle work, fine finishing |

| Bowl Gouge | Deep flute, reinforced shaft, fingernail profile | Shaping bowl interiors and exteriors, controlled shear scraping |

| Parting Tool | Spit point blade and accurate cutting, right-angled cutting | Severing workpieces, defining tenons, cutting narrow grooves |

| Scraper | Negative rake angles, burred edges, smoothening surfaces | Smoothing surfaces, smoothening profiles, trueing surfaces to flat |

| Skew Chisel | Angled blade, 45° presentation, silky smooth planing | Planing smooth surfaces, creating fine details, challenging but versatile |

The six key wood lathe turning tools each exhibit distinct performance characteristics that make them ideal for specific application scenarios. These include; rough gouge turning for the removal of wood, detail turning using spindle gouges, hollow turning using bowl gouges, turning off the surplus using parting tools, turning the surface to smooth using scrapers, or planing using skew chisels. Wood turning tools must be utilized depending on the turns for wood turning effectiveness to be achieved.

What Pricing Factors Should Be Considered When Optimizing Woodworking Turning Costs?

To effectively optimize wood turning costs, manufacturers must move beyond simple material prices. A strategic approach involves analyzing all contributing pricing factors and implementing targeted strategies for robust cost control, transforming raw data into actionable savings and a competitive edge.

- Strategic Tooling Lifecycle Analysis: The cost control process entails evaluating the total cost of ownership regarding the tool. Cost management further comprises determining the lifetime usage of tooling substitutes as well as their function. A data-driven analysis helps choose the most economical tool grade, balancing initial price with durability to effectively optimize wood turning costs over time.

- Production Efficiency Optimization: The major considerations during pricing factors are based on the efficient operating time of machines and also the production rate. The cycle time can further be reduced due to enhanced setup times based on innovative tooling path optimization methods and quick-change devices. Reduction in the setup and non-productive times directly impacts a cut-down in the unit price for production.

- Material Waste and Quality Management: Scrap and rework are significant, often hidden, pricing factors. Implementing precise programming, stable fixturing, and in-process quality checks minimizes waste. Controlling scrap rates is a direct and powerful method to optimize wood turning costs and improve overall profitability.

It can thus be concluded that an effective process plays a crucial role in optimizing the cost of wood turning. The manufacturers would thus be able to deal with the cost control using the analysis of the identified factors. In fact, the effective process identified is the best method to optimize wood turning costs.

How To Balance Cost And Quality Requirements When Selecting CNC Woodworking Turning Tools?

The CNC turning tool selection operation is one of the issues to consider, and this area affects the production costs and the quality of the products. The task of cost-quality balance is a great challenge in this area.

Tool Performance and Durability Assessment

The most relevant feature of the CNC turning tool selection is linked to its geometry, coating, and material. Even though very advanced tools with advanced coatings can be expensive, longer tool life and surface finish capabilities offset those costs. This systematic assessment ensures tools meet the required performance requirements for dimensional accuracy, surface quality, and production consistency.

Cost-Performance Analysis Framework

Cost-quality balance consideration of cost and quality with respect to the cost of ownership or purchase requires taking into account tool life, replacement rates, and costs of downtime and scrap. By conducting tool life testing and monitoring machining quality across different tool grades, manufacturers can identify the sweet spot where tool performance aligns with project performance requirements without unnecessary overspending.

Application-Specific Optimization

Wood type and part geometry impose the necessity of application-specific approaches for the CNC turning tool selection. Hardwoods need application-specific tools that are stronger and have specialized shapes. For softwoods, generalized HSS tools would suffice. Depending upon the complexity of the part, details, tolerance levels, and the volumes involved, application-specific tools might prove economical or the generalized ones would do.

Continuous Monitoring and Data-Driven Decisions

Observation of the performance of the processes in which the tools will be used will provide important insights to find the optimal cost vs. quality tradeoff. Based on the observations of the data concerning the usage of the tools, surface quality, and dimensional abilities, certain decisions can be made regarding whether to upgrade or replace the tools.

In summary, successful CNC turning tool selection is a strategic process that balances technical performance requirements with economic considerations. From the process of assessment, evaluation, comparisons, as well as overseeing the manufacturing process, there is a chance to make the right cost-quality balance, which gives peak performance at a reasonable price.

Figure 3: Wood turning sets featuring replaceable carbide inserts for cnc by LS Manufacturing

What Are The Key Factors Affecting The Pricing Of Woodworking Machinery Processing?

Understanding wood machining pricing factors is essential for making informed manufacturing decisions. The total cost of wood machining services is determined by several key elements that collectively impact the final price, and transparent pricing models help clients understand where their investment goes.

Material Costs and Complexity

The biggest single pricing influencer in wood machined prices is the species of wood chosen for a task. Exotic hardwoods, like those used in better grades of plywood, are considerably pricier as a material option than softwoods. Moreover, the effect of the mentioned complications of part design, such as the presence of complex details, tight tolerance limits, or specific geometric shapes, on material loss during processing makes it one of the factors being considered in determining the wood machining pricing factors.

Processing Time and Labor

Ultimately, the time spent machining the part-that is, the time invested in setup time, programming time, as well as the machining time itself-is the most expensive aspect. Of course, some parts may need several operations or heavy tool changeovers; others may need custom fixturing schemes, so such parts will naturally be labor-intensive.

Tooling and Equipment Wear

For CNC machining, tooling expenditure, especially end mill bits and drill bits, that need to be disposed of from time to time depending on the materials that are being cut, is very high. Other than that, maintenance of these machines, along with their depreciation, adds to these expenses.

Overhead and Operational Expenses

Besides the cost involved in the unit, there are facility overheads to be accounted for. The overheads consider usage of electricity, usage of compressed air, usage of coolants, and maintenance. And then there are operating costs along with profit margins that need to be added to this total cost. A truly transparent pricing approach breaks down these overhead allocations to provide clients with a complete picture of all wood machining pricing factors.

In summary, wood machining pricing factors encompass a comprehensive range of key elements from material selection to operational overhead. In selecting to price openly and honestly, companies like LS Manufacturing make it possible for customers to make informed and financially prudent decisions in order to further manufacturability and understand the full value equation related to professional wood machining services.

How To Achieve An Economical And Efficient Woodworking Turning Solution?

It would be effective in achieving the cost-effective wood turning through properly managing the balance between productiveness and the utilization of the resource. The development of efficient solutions in the maximization of productivity and wastages would be imperative in answering the first problem.

Process Optimization through Parameterization

The foundation of cost-effective wood turning is systematic process optimization. By conducting parametric experiments to determine the optimal cutting parameters for each wood species, manufacturers can significantly enhance machining efficiency. This data-driven approach ensures the right combination of speed, feed, and depth of cut for superior results.

Customized Tooling Solutions

Optimization of efficient solutions for tooling is a very important thing for efficient solutions. The customized design solution for tooling, based on wood type and the product to be manufactured, marks material transformation in performance. In doing so, it greatly diminishes the cutting time.

Measurable Performance Gains

The employment of efficient solutions such as these ensures a massive performance gain. Various companies, like LS Manufacturing, have reported stellar performance results, such as 40 percent efficiency in processing and a 50 percent tool life extension. The direct outcome of such solutions is reduced production cost and reduced lead times.

Therefore, in the end, the cost-effective wood turning is achieved through the method that is dichotomous — process optimization as well as smart tooling. Because of the strengths of the parameterized method as well as the use of personalized tools, the chances of having opportunities for efficient solutions with enormous cost savings as well as quality with fast turnaround time are quite likely.

Ensuring Quality And Cost-Effectiveness In CNC Wood Turning?

Specialized wood CNC turning services are required if quality production is desired. For a service to be genuinely useful, a certain finesse is involved, which entails a pair of highly essential elements: a good quality level and effective cost control.

- Quality Assurance through Systemic Processes: Quality is assured in trustworthy vendors such as LS Manufacturing through a comprehensive quality assurance process that is conducted within the firm. This is done through material testing and finish checks of the end product, including wood CNC turning components.

- Cost Control via Strategic Optimization: While cost control would seek avenues of reduction, cost control through strategic optimization has optimization as its sole objective. Strategic optimization is possible by making use of high-end tool management systems for maximizing equipment life, production strategy through minimization of waste, and manufacturing know-how for optimized cutting parameters.

- Synergy for Client Value: This, on its own, will result in a very useful integration of quality assurance procedures with cost management practices that will be of great value to the client in achieving well-finished, accurately proportioned wooden components at an affordable cost.

In short, this is how the best in wood CNC turning services is realized through a symbiotic process; which combines a holistic framework of quality assurance with intelligent processed ways of cost control of doing the services.

Figure 4: Key tools for efficient and economical CNC wood lathe work by LS Manufacturing

LS Manufacturing Cost Optimization For High-End Solid Wood Carved Components

This is only one example of how focused, technical undertakings addressed key production and CNC turning cost control issues for this upmarket furniture producer. In a collaboration when the client was experiencing serious production downtime and cost issues, the comprehensive solution with the LS Manufacturing group ensured superior client benefits.

Client Challenge

When the luxury furniture maker faced production issues in the manufacturing of rosewood carving detail pieces, the maker experienced the effect of using the traditional tools for the production of the pieces because the tools wore out quickly, thereby giving the pieces variable qualities. Every item produced experienced a cost overrun of 50%.

LS Manufacturing Solution

LS Manufacturing adopted a holistic solution for its problems based on scientific observation. The holistic solution involves an upgrade of better coated tools, a different method of cutting parameters appropriate for a certain type of hardwood in use, and a different method of cooling during the machining process. The holistic solution encompasses every aspect relating to the high rate of tool wastage and variability.

Results and Value

The outcome developed in the project has been transformative in nature in its approach. The life of the tools has been improved by 200%, thereby decreasing the cost control by 40% for each piece. The quality of the output has a qualification level of 99.2%, and the total delivery lead time has been reduced by 35%. The above-mentioned quantitative outcome percentages for the customer facilitated in making a clear point that the project is definitely profitable and on time, resulting in defining the foundation for developing trust in partnership in relation to supply chain operations.

It is a model example of a scientifically sound solution that is system centric and a great way to overcome such a tough task as there is in the manufacturing sector, and, again, the issue question posed is what needs to be overcome as a challenge in tool wear and process variation, and, LS Manufacturing has certainly done this and done it well for the benefit of its customer as it has found its edge.

This cost reduction technique of 40% can now be applied to your wood carving work.

Innovative Application And Benefit Analysis Of Advanced Tooling Technology In Woodworking CNC Turning

Highly advanced advanced tool technology are completely changing the paradigm of wood CNC turning. Wood turning innovative applications based on new material and new designs mean more than just developments as they are offering great benefits in the area of precision wood turning operations and establishing a new benchmark of excellence in the sector of wood turning.

Research & Development of Tool Materials and their Coating

The future of high-end advanced tool technology. Diamond like carbon coatings along with nanocomposites help to keep heat & friction low, and there are very advanced grades of carbides that help a lot in giving toughness to tools. These innovative applications directly translate to exponentially longer tool life and the ability to machine abrasive or dense woods with unprecedented consistency.

Geometric Design and Application Intelligence

Other than the materials, there has been a transformation in the geometry of the tools. The design of the chip breakers, with knowledge of the angles and the specialized flute design, is applied depending on the type of wood and the operations to be carried out. Again, the result of benefit analysis leans in favor of the applied intelligence.

Measurable Impact on Production Economics

The advantage in advanced tool technology comes in performing even the entire range of benefit analysis on the applications. The important key areas of focus are the increase in the tool life of 40-60%, reduction in the cycle time of 20-30%, and reduction in the scrap rate of the total process.

As it has been pointed out above, the incorporation of advanced CNC trning tool technology is a significant driving force or tool for success at the manufacturing level. Utilizing these innovative applications and making informed decisions based on benefit analysis, it is possible to achieve a better finish quality, increased speeds, and enhanced profit-generating capabilities. This makes it possible to gain a competitive advantage even at the level of precision woodworking.

FAQs

1. What is the cost of tooling in terms of total cost of woodworking CNC turning processes?

Cost of tooling will vary between 15% to 25% for the overall machining cost. Effective management of tools is helpful in reducing the overall cost of machining.

2. On which principles should one base a choice of tools in connection with types of wood?

For hardwoods, one of the key requirements would be wear resistance, whereas for softwoods, one of the requirements would be high rates of chip removal. The use of special cutting tools would, therefore, be required in favor of one type over the other.

3. How to assess tool life and replacement cycle?

The life span of the tool would then depend on the intensity or quality of machining, as there would be an early warning system in place for the users to replace the tool.

4. How to control tool costs in small-batch production?

We offer tool rental and sharing solutions to reduce tooling costs for small-batch projects.

5. What equipment will be needed for machining wooden items of special shapes?

Each special cut-off tool is made in a design specific to the product to ensure a high level of precision and efficiency during the machining process.

6. How can the impact of tool wear on machining quality be monitored?

We have created an online monitor to check real-time status of the tools and ensure a steady quality of machining.

7. Are the recommendations related to training as well as optimization in the usage of tools?

We offer training and services to effectively utilize these tools, which will benefit the customer.

8. What are the methods you employ to manage the influence of wood quality variation on tools?

A material database has also been created. The parameters for processing are varied depending on the batch number of the wooden material.

Summary

In choosing the right scientific tool and optimizing the process, it is possible to highly improve both the economic efficiency and the quality of the woodworking turning on the CNC turning machine. For LS Manufacturing, professionalism in technical strengths and experiences was motivating factors when choosing the scientific tool and optimizing the processes for turning.

Our team of experts at LS Manufacturing can evaluate your wood working needs absolutely free and assist you in cost optimization. You are free to contact us whenever you need technical help.

Upgrade your turning process now, get a customized solution, and reduce both tooling costs and production cycles.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.