CNC milling provide the most viable solution to the pressing challenges in this environment of intense competition.on one hand, driving manufacturers hard is the dual demand for high precision and consistency of complex parts; on the other hand, a need exists to reduce lead times and control costs increasingly responding in small lots to diverse market demands. These problems largely come from the fact that traditional methods depend too much on human labor, which is inefficient, prone to a high error rate, and inflexible.

By addressing these basic problems, the CNC milling process builds directly onto the bedrock of modern precision manufacturing. The ensuing paper will provide in-depth analysis of such development based on operative principles, steps of the process, materials involved, advantages, and an engineering-based case study on how LS Manufacturing applies this technology so as to bring outstanding value to clients. In such a way, practical insight will be provided both to the engineer who wants responsible partners and to the manager who wants, too, to increase his knowledge about this life-changing technology.

Quick Reference Guide To CNC Milling

| Topic | Summarize the Keypoints |

| Working Principle | It is based on a very simple principle of the use of the computer-controlled rotating tool, which moves on a predefined route for the exact removal of the material. |

| Main Steps | Design on CAD, programming on CAM, setup, adjustment of the parameters, and then automatic machining. |

| Common Operations | It includes face, end, pocket, contour milling, and drilling starting from roughing to finishing. |

| Appropriate Materials | Metals, plastics, composites, ceramics. |

| Key Benefits | High accuracy; would automate; ability to machine complex pieces. Productivity and flexibility. |

| Selection Criteria | Degree of part complexity, batch size, material, budget, and requirements concerning surface finish. |

Overall, what characterizes CNC milling is high-precision computer-controlled manufacturing of material by removal. For any principles of CNC milling, which are needed to support various types of milling machining operations and materials include design, programming, setup, automated machining, and inspection. Key listed major advantages of the technology in the complex part manufacturing are accuracy, automation, and flexibility. Specification of the part, volume, material, and finish needs determines the choice of any given technology. This technology also ensures that production is efficient and reliable in performance for many industrial applications.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The practical insight in this guide was taken from extensive 5-axis CNC machining at the front lines of LS Manufacturing. Our recommended methodologies-from fixturing to finishing-continuously get vetted against foundational standards for the Society of Manufacturing Engineers (SME) so the advice on tool selection and machining parameters is well-founded in proven manufacturing science, not just anecdotal experience, providing a sound technical basis for your projects.

By definition, complex machining implies controlled and predictable workflows for the highest degree of precision. Principles of the American Production and Inventory Control Society (APICS) form part of our process design in order to manage quality and efficiency systematically. Applying this type of discipline in everything from aerospace machining alloys through to medical-grade plastic provides repeatable accuracy and on-time delivery-so vital in advanced manufacturing across all our client sectors.

The LS Manufacturing CNC guide pulls together the shop-floor-proven techniques and the industryendorsed frameworks that deliver actionable strategies. This is, therefore, a strong fusion of technical standards with operational discipline, forming a sound basis. We strive to translate this deep, practical expertise into clear guidance that lets your enterprise cut through the tangles of modern CNC milling.

Figure 1: A complete and varied collection of milling cutters by LS Manufacturing

What Is CNC Milling?

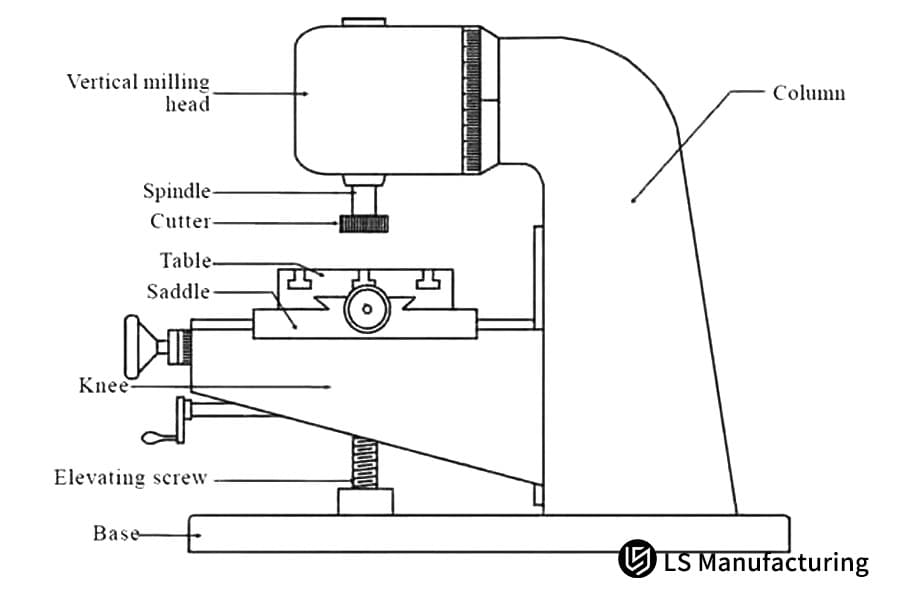

What is CNC milling? Generally, it refers to tailor-made parts that involve the use of a computer control system with the use of a machine tool capable of material removal by moving rotating cutting tools relative to the workpiece. Working Principle: The idea behind it is the processor will formulate the method of processing, choose parameters and input a program into the CNC device, and under the control of the servo motor thereafter, the tool and workpiece will go into relative motion along the set trajectory to perform the cutting and automatic processing.

Does your part design seem complex? Consult our technical team today for a free CNC machining design guide and DFM that will help optimize not only your design right from the basics but also improve manufacturability while shaving off costs.

How Does CNC Milling Work?

The CNC milling process is quite accurate and automated, normally undertaken for complicated forms of parts from metals, plastics, and many other materials. To fully understand how CNC milling works, it is essential to follow the step by step CNC milling methodology. The detailed process shall come forth below through the LS Manufacturing team.

- Product Drawing: Using the computer-aided design software, CAD should draw the size and position for holes to be milled and grooves demarcated in the drawing, according to the product.

- Select the cutting tool: .The choice of the cutting tool shall correspond to the type of material a product is made of and its treatment. If such the aluminum alloy material, for example, then a rigid carbide thread-drilling and milling cutter could be applied to it.

- Design the cutting path: According to the drawing, check the cutting route and the sequence for processing a product to make the whole process effective.

- Setting of machine tool parameter: Based on the hardness of materials and the requirement of the product, proper cutting speed, feed speed, and cutting depth is selected. For example, if the material is an aluminum alloy, then the speed of the milling cutter can be set as 2,000 r/min, the cutting speed is 314 m/min, milling feed is 0.06 mm/tooth, etc.

- Install the workpiece: Fixation of work in a milling machine in such a way as to render it stable, yet positioned precisely for the treatment of the workpiece, is made by fixtures or any other tooling installations.

- Processing operation: First of all, make sure that the workpiece is fixed firmly, and the machine parameter settings are correct. Then it can start to mill. In the processing, pay attention to the situation of the cut in order to timely adjust the cutting parameters and ensure a good quality can be obtained.

- Processing inspection: Check for the finish surface after the milling is done. This may be in terms of dimension inspection, surface quality, etc.

- Post-processing: A well-structured approach helps ensure that even projects requiring tight tolerance machining will be done efficiently with quality.

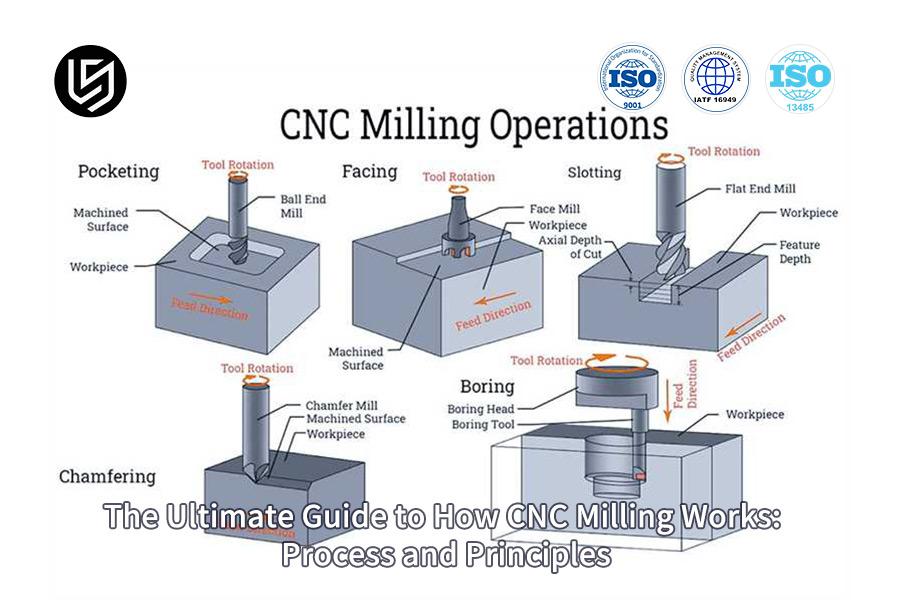

What Are The Different Types Of Milling Operations?

Of the effective ways to deal with metals, it is computer numerical control milling. In this regard, the capability of computer-controlled machine tools enables the use of rotating milling cutters to maintain material removal with high precision. In consideration of different requirements and real application situations, there exist some specific types of CNC milling. Some of the standard milling machining operations include but are not limited to: These are as follows.

- Face Milling: It is the most prevalent type of milling and is used for the milling of a flat surface, which is parallel to the tool face. Milling cutters are often installed on the spindle. There are two methods in which face milling can be done, which includes: utilizing a cutter with a particular diameter so that the workpiece can be treated in one stroke or by utilizing a milling cutter which has a diameter which needs many strokes to finish the workpiece. knife

- End milling: The axis of the tool in end milling is at a right angle to the machining plane. The kinds of shapes it generally machines are contours, grooves, and cavities; main applications can be found in advanced precision machining services.

- Copy milling: This finds an application in milling free-form or curved surfaces where the path of the tool follows the contour of the workpiece.

- Step milling: Also called shoulder milling or end milling, it is a method to process 90° shoulders or step surfaces. Flanks of the tool -the entering angle- are parallel to the axis of rotation.

- Contour milling: It is a process in which either internal or external contours of a workpiece are machined, whereby the tool path is well planned to take exact consideration of the workpiece shape.

- Plunge milling: Where the cavities to be made are deeper, the method is very effective. This special form of milling machining operation involves a long tool that is inserted vertically into the workpiece for the cut-ting operation.

- Helical milling: It is that form of milling that has a helix-like path of cutters and is usually adopted for machining cylindrical or conical surfaces.

- Point milling: It is mainly used in the processing of small holes or any other small area with complex forms. The precision is attained by a cut through very small tool movement.

- Slot milling: During the slot milling, the materials are processed for T-slots, dovetail slots and all kinds of slots.

- Drilling and milling: Even though drilling is normally a method in and of itself, it can indeed be carried out by using a milling cutter and often is via a CNC machine, showing just how flexible these integrated precision machining services are.

- Cavity milling: It consists of such milling in which inner cavities of complicated shape, like moulds, are milled. It needs a lot of precision tool path planning; therefore, among all the milling types, it is one of the most important machining operations for a complicated part.

- Rough milling and fine milling: With rough milling, lots of material is taken out by aggressive parameters; fine milling is for a superior surface finish with light cuts. It represents the whole range of milling machining operations-from bulk removal down to final detailing.

Figure 2: Chatter control and tool optimization in CNC milling by LS Manufacturing

LS Manufacturing Precision Machining Solution: Overcoming The Manufacturing Challenges Of Lightweight Landing Gear Brackets For UAVs

Of these numerous high-stake applications of precision machining, few indeed are as demanding as aerospace components, where literally every gram and every micron counts. One perfect example is our successful project to manufacture a lightweight landing gear bracket for a high-altitude, long-endurance unmanned aerial vehicle, illustrating our approach in the following sections.

Customer Dilemma

The customer required extreme lightness versus strength for the landing gear bracket of their next-generation HALE drone. The section was deep-pocketed, thin-walled, geometrically complex, integrated in the highest strength 7075 aluminum. Traditional multi-setup machining creates positioning errors and results in not controlling distortion, jeopardizing critical fatigue strength, and stalling development timelines with prior suppliers.

LS Manufacturing Solution Solution

For this complex part manufacturing, we employed a custom 5-axis simultaneous machining process led by our engineering team. Full 5-axis capability was used to ensure error-free single-setup machinings. We were able to manage the stress in thin webs using a proprietary multi-step cutting strategy. Furthermore, stringent in-process inspection has made sure that every unit meets the highest protocol of aerospace machining for dimensional integrity.

Results and Value Delivered

A final machined bracket realized a weight reduction of 15%, meeting all the targets in terms of strength and lifecycle. First-pass yield rate of 99.5% was attained with 30 percent reduction in the development cycle for the client. The successful making of this part opened up a pathway to time-to-market for this drone and created a substantial high-performance supply chain for this mission-critical aerospace component.

This project underlines the fact that any such challenge needs a partner with deep 5-axis CNC machining capability, deep process knowledge, and a rigorous quality system. We took a bottleneck and turned it into a competitive advantage with the client through an integrated solution with engineering.

Is making complicated structural parts-including lightweight and high precision-still a bother? Whatever the material, process, or performance in question, the professional team at LS Manufacturing is in a position to offer tailor-made CNC milling services. Get in touch with our aerospace project expert now, submit your part drawings, and get a tailor-made feasibility analysis and preliminary CNC machining quote!

What Materials Are Commonly Used For Custom Milling?

Aluminium

With many excellent characteristics, it thus finds very wide applications in industry due to its lightweight, high strength, easiness in processing, and good resistance to corrosion. Its density is about 2.7 g/cm³, only one-third of copper and steel, while it has very high strength. Apart from that, the electrical conductivity and thermal conductivity of aluminum are excellent, which could find wide applications in electric power, electronics, heat exchangers, etc. It is also one of the core materials in our comprehensive CNC milling services.

Commonly used aluminum alloys include 2024, 5052, 6061, and 7075 Aluminum, among others. The 2024 alloy has high strength with good fatigue resistance; hence, it finds wide applications in aircraft structures, while 5052 has excellent corrosion resistance and finds applications in the manufacture of fuel tanks and piping. 6061 displays good weldability and machinability; hence, it is popularly used in vehicle frames. High-strength 7075 Aluminum is used as a premium to manufacture high-stress parts, and this also affects the CNC machining cost tremendously, since this type has to be treated under certain conditions.

Steel

A number of steel alloys can be employed in CNC machining. When it needs to have higher formability along with greater weldability, and when parts are gears, shafts, or applications in which they withstand stresses, then the application of steel alloy may be considered. Major types of CNC steel are stainless steel, low-carbon steel alloy, and tool steel. When the parts require high strength, high ductility, excellent wear resistance, and corrosion resistance, then stainless steel is highly recommended. Furthermore, stainless steel features good workability and is well welded and polished. Low carbon steel fits when costs play an important role and the application is general.

Copper

Copper is another very popular material in machining, with quite a few unique properties. It is very electrically and thermally conductive. With its high conductivity value, the material finds perfect applications in electrical and electronic applications. Because of its good appearance, the copper alloys also find an application in manufacturing jewelry. Typical uses include wire, magnetic equipment, and jewelry.

To know how copper behaves will be an essential part of the whole CNC milling process. Some of the common copper alloys with unique properties include brass and bronze. Generally, brass is an alloy of copper and zinc. It is a very soft metal that one could treat without lubrication. Common features of brass are great electrical conductivity, good corrosion resistance, and workability. Thus, this material finds use in the manufacture of low-strength fasteners, electrical equipment, consumer goods, and piping equipment in applications not requiring high strength.

On the other hand, bronze is made up of copper and tin; added to them are other composite elements. It is dense, solid, and resistant to corrosion. Bronze has very good workability; thus it can be used for precision machinery that needs bearings, gears amongst others. Adding aluminum and phosphorus will help in improving its impact tenacity and strength.

Titanium

This CNC metal has very high strength, is light in weight, hence offering excellent strength-to-weight ratios. Adding such corrosion resistance, thermal conductivity, and biocompatibility make it suitable for CNC machining of parts intended for biomedical applications. Compatibility processes included in titanium are welding, passivation, and anodizing for good appearances and protection. Poor electrical conductivity, good thermal conductivity, and a high melting point are some of the key features of titanium.

Besides, it can be used in manufacturing mechanical parts of high performance in medical and military fields and the aerospace and automobile industries. More worth mentioning, titanium is applicable to make cutting tools for CNC machine tools.

Plastics

They have a high ranking among popular materials for machining, due to their variety and relatively lower cost, given that much faster machining times are achieved. There is an enormous amount of types categorized according to characteristics and uses: POM, ABS, PVC, among others. They are low-density and high-strength materials with high plasticity. Their application ranges from electronic and automotive industry manufacturing to environmental protection and so on. The optimum way for the CNC milling process regarding them is different from the ones regarding metals, and that difference is one more factor influencing the final CNC machining cost.

Ceramic

Apart from that, the other common non-metallic material is made of ceramics. It boasts a series of advantages: high strength, high hardness, high friction resistance, corrosion resistance, and high-temperature resistance. Among them, some common ones in industrial manufacture, electronics, and aerospace are such as alumina ceramics, silicon nitride ceramics, silicon carbide ceramics, and so on.

Figure 3: Functional anatomy of a vertical CNC milling by LS Manufacturing

What Are The Advantages Of CNC Milling?

The following table describes many of the major advantages with CNC milling:

|

Advantages |

Description |

|

High degree of automation and precision |

With a high degree of automation and precision, complicated procedures can be done without human intervention through programs already written for the task, thereby effectively raising production efficiency and reducing the possibility of human error. |

|

High flexibility |

High flexibility refers to the fact that only a few changes in programming will make the adjustment of working patterns possible when a product is designed differently. So, CNC systems meet the requirement of small-batch, diversified production. |

|

Improve production efficiency |

Such machinery carries out multi-coordinate linkage, manufacturing parts with complicated forms. In case of the need for changes in the form or size of any part, a CNC would require changes in the program, saving time in preparation for production. Most of the CNC type machines operate unattended during the whole operating cycle, increasing the productivity. |

|

High security |

Most of the operations of machine tools are automated during treatment; in this way, it reduces the direct contact of workers with hazardous machinery to make the workplace much safer. |

|

Wide range of applications |

Many uses range from aerospace, manufacture of automobiles, medicine, mold manufacturing, and other related fields. |

What Are The Disadvantages Of CNC Milling?

While there are quite a few advantages related to the whole process of CNC milling, the latter also has a set of disadvantages. A few of the major demerits related to the CNC milling have been elaborated in the table below:

|

Disadvantages |

Description |

|

High quality requirements for operation and maintenance personnel |

Compared to a normal machine tool, the requirement of quality from the operator by CNC machining is lower, while the technical requirement of the maintenance personnel is higher. |

|

Difficult to control in the processing route |

The CNC machining route is not intuitive compared with an ordinary machine tool. Besides, there are some requirements for programming and debugging skills and experience. |

|

Inconvenient to repair |

Because there is a great amount of electronic and mechanical equipment assembled in the numerical control machine tool, once something goes wrong, it may be complicated and difficult to repair. |

|

Possible processing problems |

Due to a number of possible factors that can occur during its processing, such as tool wear, incorrect cutting parameters, poor machine tool rigidity etc, the following defects may arise, such as poor surface finish, vibration or chatter, tool breakage, parts out of the tolerance range, poor dimensional accuracy etc,. |

Weighing the pros and cons of CNC milling compared to other processes such as 3D printing? Contact us for a free process selection guide to help you make the best decision based on cost, materials, and performance.

Figure 4: Fundamental subassemblies of a CNC milling center by LS Manufacturing

FAQs

1. What are the essential differences between CNC milling and turning?

CNC milling relies on a rotary tool to make the cut to a stationary workpiece and is applied to the machining of planes, grooves, etc.; turning depends on a rotating workpiece with an orbiting tool, so it is specialized for rotating bodies such as bushings. Both complement each other in a subtractive manufacturing system.

2. What is the machined accuracy by CNC milling at LS Manufacturing?

The standard accuracy of LS Manufacturing CNC guide is ±0.025mm. Where the dimensions are important, that would be under high-end equipment and stable process conditions down to ± 0.005mm. Specific indicators would depend on your particular materials and structure and thus will be evaluated.

3. What are the most important price drivers of the milled part in CNC?

The core pricing factors include: geometric complexity (time of programming), type of material, quantity of order, post-processing, and inspection standard. We recommend you provide us with detailed drawings so that we can easily deliver a transparent cost analysis for you.

4. How do you treat IP protection of clients?

We store the design documents through a hierarchical encryption system. All our staff has signed confidentiality agreements, while physical isolation has been performed at the production site. Your IP rights will always stay in your ownership, and no technical detail will be disclosed to any third party.

5. Can you manage small-batch prototyping to mass production?

We provide detailed production requirements from single prototypes to batches of tens of thousands and make sure quality is maintained by a standardized process system in the whole life circle of products. Ensure standards of quality remain constant irrespective of volume.

6. What is the average time from receipt of drawings to shipment?

Delivery time is about 5-7 business days in standard complexity for prototype delivery. The lead time of bulk orders is estimated by specific quantity, which directly influences the CNC machining cost. We have established an agile production system and continually optimize our supply chain to shorten the delivery times of all our CNC milling services.

7. Do you give feedback if some design issues come up in the manufacturing process?

Yes, we do. We offer free CNC machining design guide, and DFM analysis. When reviewing drawings to make sure that your part is optimized for the CNC milling process, our engineers proactively advise on design points that may affect the cost of manufacturing, the lead times, and quality.

8. What else does LS Manufacturing offer to support services besides milling?

We offer everything from CNC turning to sheet metal treatment, 3D printing, and metal stamping under one roof. This means more than one part can be fabricated from the very same supplier to simplify supply chain management.

Summary

CNC Milling at Its Finest While laying down the core foundation for modern manufacturing, CNC milling has the capability to yield unparalleled precision and effectiveness even in the most complicated fabrications. From CAD design through toolpath programming, machining, inspection, and post-processing, this end-to-end workflow ensures a part created with very consistent and reproducible results. From aerospace to the medical device sector, this continuously revolutionizes and makes possible innovations that call for the most in terms of accuracy and repeatability.

Ready to put CNC milling to work in your next project? Contact LS Manufacturing today. Let our engineering review your design for feasibility and provide a competitive quote. From the most intricate concept to great performance, on-time delivery, and at the highest levels of quality, let us discuss how your vision can be brought to life with our experience. You can upload your drawings today and take the first step toward excellence in manufacturing.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.