Plastic injection molding is a plastic processing technologywidely used in the manufacturing industry. It converts plastic raw materials into plastic products of various shapes and sizes by precisely controlling the melting, injection, cooling and solidification processes of plastic. This article will introduce in detail the working principle of plastic injection molding and its workflow.

What is plastic injection molding?

Plastic injection molding, also known asi njection moldingor injection moulding, is a widely used plastic processing technology. It injects molten plastic material into a precisely designed mold cavity at high pressure, and after the plastic cools and solidifies, the products in the mold are taken out to obtain plastic products that are exactly the same shape as the mold cavity. This process can not only achieve large-scale, high-efficiency production, but also produce plastic products with complex shapes, precise dimensions, smooth appearance and stable quality. Therefore, it is widely used inautomobiles, electronics, consumer goods, medical equipmentand other industries.

Why is the plastic injection molding process so important?

Plastic injection molding exhibits multiple advantages in mass productionthat make it an integral part of modern manufacturing. The following are the main advantages of plastic injection molding in mass production:

| Advantages | Elaboration |

| Efficient production | plastic injection molding is praised for its fast manufacturing cycle, usually between 30 seconds and 1 minute per production cycle. |

| High precision | Through plastic injection molding technology, products with complex shapes and precise dimensions can be manufactured. |

| Complex parts | This method can design complex shapes and structures, especially thin shell parts of various types of equipment. |

| Material versatility | It can handle a variety of mold andthermoset materialsincluding PS, ABS, PA, PP, PE, PVC components. |

| Low waste | The goal of this process is to significantly reduce the loss of material, thus helping to reduce costs and provide benefits to the environment. |

| Mass Production | Once the mold is successfully created and configured, the plastic injection molding machine is able to manufacture large quantities of parts in a very short time to meet the needs of mass production. |

How Does plastic injection molding work?

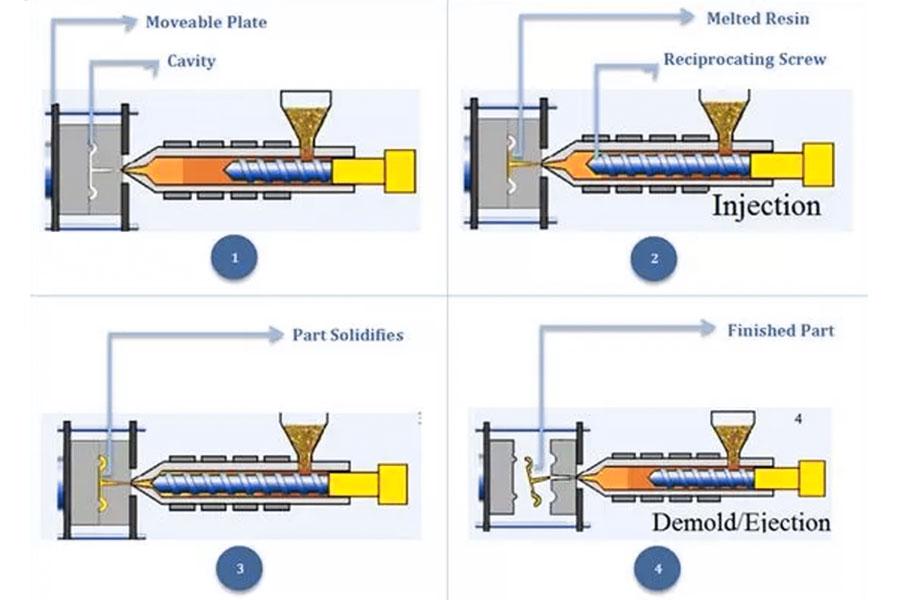

Theworking principle of plastic injection moldingis similar to that of a syringe for injection. It is a cyclic process. Each cycle mainly includes stages such as quantitative feeding, melting and plasticizing, pressure injection, mold filling and cooling, and mold opening and removal. The following is the process Detailed workflow:

- Raw material preparation:Select appropriate plastic raw materialsand dry them to remove moisture and other volatile matter in the raw materials to prevent bubbles and defects during the plastic injection molding process.

- Melting:Add the dried plastic particles into the barrel of the injection molding machine through the hopper. Through the heating of the barrel and the rotation of the screw, the plastic particles are melted into a molten state. Plasticization is the prerequisite for realizing and ensuring the quality of molded products.

- Injection:When the plastic melt reaches the predetermined temperature and pressure, the screw or plunger of theplastic injection molding machineinjects the molten plastic into the closed mold cavity through the nozzle at high or low speed. Injection must ensure sufficient pressure and speed.

- Pressure holding:After the plastic fills the cavity, continue to maintain a certain pressure to compact the melt, increase the plastic density (densification), ensure that the plastic fully fills all corners of the mold, and reduce the shrinkage and deformation of the product to compensate for the plastic contraction behavior. The pressure holding stage should continue until the gate is solidified and sealed.

- Cooling:After the holding phase, keep the mold closed and let the plastic cool and solidify in the mold until the plastic becomes hard enough to remove the product. Cooling time depends on the size, thickness and type of plastic used. A well-designed cooling system can significantly shorten molding time,improveplastic injection molding productivity, and reduce costs.

- Mold opening and removal:After the plastic product cools and solidifies, the mold is opened and the product is taken out of the mold through an automated robotic arm or other manual tools. After taking out the plastic part, the mold is closed again and the next cycle is carried out.

- Post-processing:There may be gates and flash edges on the product. These excess parts need to be removed by shearing, grinding, etc. to make the surface of the product smooth. Afterwards, the products are inspected in terms of size, appearance and performance to ensure that they meet quality requirements. Depending on the use requirements of the product, some post-processing may be required, such as printing, spraying, electroplating, etc., to increase the functionality and aesthetics of the product.

What Are the Common Applications of Plastic Injection Molding?

1.Automotive industry

Plastic injection molding can be used to produce automotive interior parts(such as dashboards, door panels, seats, etc.), exterior decorative parts (such as bumpers, light housings, car logos, etc.) and functional parts (such as water tanks, pipes, fuel tank, etc.). With the rapid development of new energy vehicles,plastic injection molding also plays an important role in the application of lightweight materials.

2.Home appliance industry

Plastic injection molding is widely used in the manufacture of casings and internal components of household appliances, such as casings and internal structural parts of televisions, refrigerators, washing machines, air conditioners, etc. Theseplastic products not only look beautiful, but also have good durability and insulation properties.

3.Medical device industry

Injection molding technology is widely used in the production of disposable medical devices(such as syringes, infusion sets, blood collection devices, etc.) and medical device casings. These products need to meet strict hygiene and safety standards, and injection molding technology can provide high-precision, high-cleanliness manufacturing solutions.

4.Electronic device industry

Plastic injection molding technology plays a key role in the production of casings for electronic productssuch as mobile phones, computer accessories, keyboards, mice and MP3 players. At present, the production of electronic components mainly uses plastic injection molding technology, including plastic injection mold design, material selection and processing methods. This batch of products needs to have a refined appearance and a high degree of structural strength, and injection molding technology not only meets these standards, but also provides excellent electromagnetic shielding and insulation properties.

5.Packaging industry

Plastic injection molding technology is also widely used to produce various types of packaging containers, including but not limited to bottles, caps, and food packaging boxes. For example, plastic bottles used for the production of beverages and dairy products and bottle caps used for the production of cosmetics and pharmaceuticals are manufactured using injection molding technology. This batch of packaging products must meet food safety, moisture-proof and impact-resistant standards, and plastic injection molding technology can provide us with high-precision and lower-cost production solutions.

6.Toy and model industry

Plastic injection molding technology has the ability to produce children's toys and models of various shapes and colors to meet the diverse needs of the market. At present, it is mainly used in automobile, electronics, machinery, construction and other industries, such as children's cars, children's airplanes, toys and other similar plastic products. Such products generally require exquisite appearance, long-lasting durability, and safety and non-toxic properties, and plastic injection molding technology can provide high-quality production solutions for these products.

7.Building materials industry

Plastic injection molding technology is also widely used in the manufacture of building materials, such as door and window frames, various pipes and decorations, etc. Plastic pipes are mainly used for indoor decoration and outdoor laying in construction. Their advantages are light weight, high strength, corrosion resistance and not easy to deform. This batch of products not only looks elegant and durable, but also helps improve construction efficiency.

8.Industrial parts

Plastic injection molding technology can produce a variety of industrial parts, such as gears, valves and connecting parts. These parts are widely used in mechanical equipment and machinery, and their manufacturing requirements are high precision and high-quality mechanical properties.

9.Aerospace industry

Plastic injection molding technology has been applied to manufacture parts with precise structures and high precision requirements, such as aircraft interiors, sensor casings, and various connectors. In order to meet the standards of high strength, high temperature resistance and light weight, these components must be met. Plastic injection molding methods provide a solution for high-quality manufacturing.

10.Furniture Industry

We have always relied resolutely on plastic injection molding technology to create furniturebecause this method is unique in terms of durability, aesthetics and design innovation. This technology helps to perfectly combine functionality and design style, making it a leading product in the furniture manufacturing industry. For example, the following structures can be listed: chair bases and armrests, table legs and support mechanisms, chairs and tables placed in the open air, office furniture combinations, and modular shelf modules.

11.Agricultural tools and equipment

Plastic injection molding has revolutionized the agricultural industry, providing strong, weather-resistant components essential to modern agriculture. The technology excels at efficiently producing large quantities of durable items, making it ideal for agricultural applications. Such as: dashboard housings, knobs and levers for tractors and harvesters, sprinkler heads and connectors for irrigation systems, containers and storage boxes, shovels and rakes, etc.

How to choose a plastic injection molding manufacturer?

1.Professional Competency Assessment

Understand the professional ability and experience of service providers in the field of injection molding, including the product types, materials, processes and other they are good at. Investigate the r & d and development capabilities and technological innovation capabilities of service providers, which can be achieved by reviewing their technology patents, r & d results and cases.

2.Production Capacity Investigation

Understand the production scale, equipment configuration, and line automation to ensure they can meet your production needs. Ask the service provider about production cycles and delivery times to ensure they can deliver on time.

3.Quality Control System

Understand the quality management system and certification of service providers, such as ISO 9001, to ensure that they have perfect quality assurance capabilities. Ask the service provider about the quality testing methods and standards, as well as their defective product processing procedures, to ensure that the product quality meets your requirements.

4.Service And Support

Understand the pre-sales and after-sales service support of service providers, including technical support, training, maintenance, etc. Investigate the response speed and problem-solving ability of the service provider to ensure timely and effective support in the cooperation process.

5.Cost And Price

Ask service providers for quotes and cost structure to see if their prices are reasonable. When comparing prices, do not just pursue the lowest price, but to consider the comprehensive cost performance, including product quality, delivery time, service support, etc.

6.Sustainability

Understand the environmental policies and sustainability practices and ensure that their production process complies with environmental regulations.

Investigate the measures and results of service providers in resource conservation, energy utilization and waste treatment.

7.Word Of Mouth And Credibility

To understand the service provider’s reputation and reputation in the industry, we can obtain relevant information by consulting customer reviews, industry reports, media reports, etc. If possible, you can visit the service provider’s production site and management situation, so that you can have a more intuitive understanding of their strength and level.

Why choose LS custom plastic injection molding services?

At LS, whether you need prototype parts manufacturing or mass production, we have the corresponding capabilities and experience to meet your needs. We are committed to providing reliable, quality parts to assist you with success in the competitive automotive market.

- Rapid Quotation:Just upload the CAD file, you can quickly understand the manufacturing cost and keep abreast of the order status.

- Quick Molding:LS has extensive experiencein prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

- ISO Attestation:LS is a ISO 9001 certified manufacturing company, which means that we employ internationally recognized best practices to develop your products and ensure that they meet the standards, regardless of the complexity of the design.

- Customized On Demand:Our auto parts manufacturing process is fully customizable according to your specifications, sizes, materials and surface requirements to ensure meeting your unique needs.

- Express Delivery:We are committed to providing, fast manufacturing and delivery to meet your production needs while providing you with greater flexibility to quickly respond quickly to market changes. Longsheng is a partner of your auto parts needs.

FAQs

1.How does injection molding work step by step?

Injection molding is a cyclic process, and each cycle mainly includes the following steps: ① Mold closing: close and clamp the mold to prevent and resist the pressure generated by the injection of raw materials into the mold cavity. ②Injection unit advances: After the mold closing is completed, the injection unit advances until the nozzle presses against the mold. ③Injection filling: The molten raw material is injected into the mold cavity. After the amount of raw material close to the required product is injected into the mold cavity, the raw material is compressed to a certain pressure and the mold is completely filled. ④ Pressure holding: The molten raw material will shrink (specific volume change) after cooling in the mold. After filling is completed, continue to maintain a certain injection pressure until the glue inlet solidifies to prevent the product from shrinking. ⑤ Cooling: After the product is formed in the cavity, it must continue to cool until it solidifies and can be taken out.⑥Injection unit retreats: After pre-molding and cooling are completed, the injection unit retreats a certain distance and waits for the next cycle. ⑦ Mold opening: After the product is cooled, the mold closing pressure is released and the mold opens. The opening distance depends on the space required to take out the product. ⑧When the mold is opened to the position, the ejection mechanism ejects the product and leaves the mold cavity.

2.How do plastic injection moulding machines work?

Theworking principle of the plastic injection molding machineis similar to that of a syringe for injection. It uses the thrust of the screw (or plunger) to inject the plasticized plastic in the molten state (i.e. viscous flow state) into the closed mold cavity. The process of obtaining finished products after curing and shaping. The workflow of the injection molding machine mainly includes steps such as quantitative feeding, melting and plasticizing, pressure injection, mold filling and cooling, mold opening and picking. After taking out the plastic part, the mold is closed again and the next cycle is carried out.

3.What is the working principle of injection molding?

Theworking principle of injection moldingis to take advantage of the fact that plastic can melt into a liquid after being heated to a certain temperature. The molten liquid is injected into a closed mold cavity with high pressure. After cooling and shaping, the mold is opened and ejected to obtain the desired plastic product. . This process mainly includes mold closing, injection filling, pressure holding, cooling and demoulding stages.

4.What is the process of plastic molding?

Theplastic molding processvaries depending on the molding method. The plastic injection molding process involves multiple steps, each of which is critical to the success of the process. These steps include raw material preparation, melting, injection, maintaining pressure, cooling, mold opening and demolding, and post-processing. Plastic molding also includes other methods, such as extrusion molding, compression molding, blow molding, etc. Each method has its own specific process and applicable scenarios.

Summary

Thesteps of plastic injection moldinginclude raw material preparation, melting, injection, maintaining pressure, cooling, mold opening and demolding, and post-processing. Plastic injection molding is an efficient, precise, flexible and economical method of processing plastics. By precisely controlling parameters such as injection speed, pressure and temperature, plastic products of various shapes and sizes can be produced. With the continuous development of manufacturing industry, plastic injection molding will be applied and promoted in more fields.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.