5-axis CNC machining services could be required very commonly regarding curved surface components, although engineers could be presented with very different quotations. This could be attributed to a lack of transparency regarding what is included regarding curved surface component costs, as there is very little that manufacturers could say regarding kinematics, programming, and precision requirements.

In relation to trying to achieve a clearer understanding of the technicalities of 5-axis machining, it is the purpose of this paper to highlight these technicalities and shed light on key elements which have economic expenditure implications, proving beneficial because it allows for a fair quote to be established by LS Manufacturing’s standard assessment process and thus reach a conclusion. How beneficial a fair quote is created can be established by having a standard understanding of key technical elements.

5-Axis CNC Machining Capabilities Quick Reference

| Section Title | Important Points Highlight |

| Introduction | There are unclear quotations for engineers of complex components. The suppliers are not clear regarding pricing. One observes the emergence of 5-axis technology. One could speak of the quoting technique of an LS Manufacturing. |

| Axes Machining | Process coupled with two rotary axes. Supports turning of complex shapes with a single setup. Prevents errors that result from multiple setups in a fixture. |

| Key Cost Factors | Machine configuration and capabilities. Advanced programming and simulation time. Specialized tooling and precision workholding. Part tolerances and surface finish requirements. Component complexity and material selection. |

| LS Manufacturing Assessment Process | Standardized assessment list utilized. Entire cost drivers analyzed. Open quote breakdown utilized. |

| Conclusion | Understanding the concepts of axes is necessary in analyzing quotations properly. Cost transparency results in ideal procurement. Joint operation with a competent supplier may be value-based. |

Regarding selection of the correct service based on 5-axis machining, understanding the relevant critical technologies in cost is the requirement. Technologies like machine kinematics, programming, and part complexity play a major role here. A correct supplier can help you make the correct choice as the supplier can provide insight into the aspects mentioned above.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are numerous websites on which you can find descriptions of 5-axis CNC machining. Now, you might ask yourself why you are so very interested in this particular case. To begin with, learning all of this information is done from a theoretical point of view. However, for me, personally, learning all this knowledge is applied within our workshop. As our workshop is where our knowledge is implemented, we not only know but apply all this knowledge on a daily basis to slice hard shapes from hard materials.

Precision is the focus of our area of expertise. Our area of expertise includes complex aerodynamic parts for the aerospace industry, which demand enhanced aerodynamics and medical devices for faster integration processes. Following directly from our area of expertise using the best practices offered by PTC (Creo) for design and Additive Manufacturing (AM) on the development of the prototype necessitates direct recommendations.

Our company is capable of supplying tens of thousands of 5-axis machined parts per year. Each experience is a new chance for acquiring real experience concerning know-how, be it the task of tool path optimizations for machining components with the material Inconel or the speed and precision process. What can be extracted from the article and the lessons is experience.

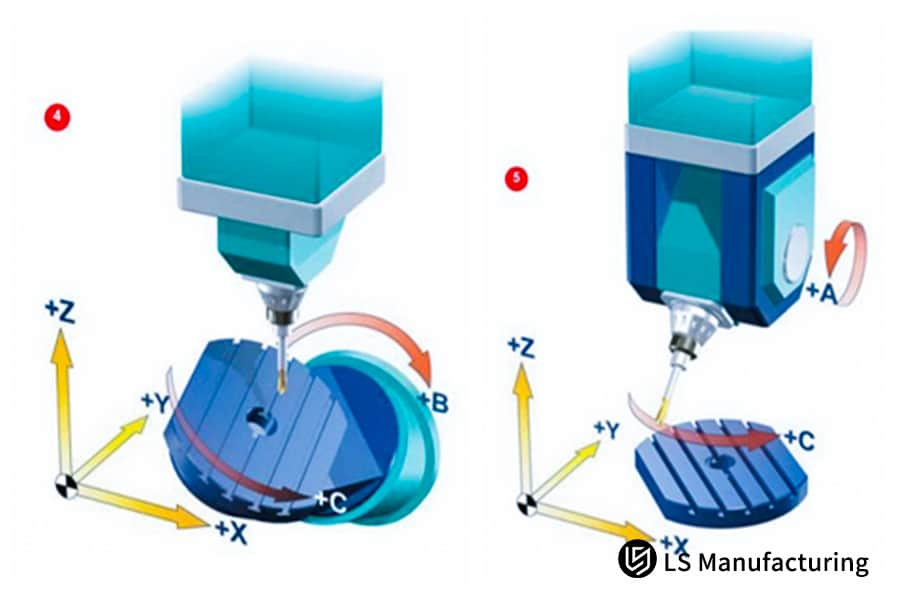

Figure 1: Annotated diagram illustrating the axis motions of a 5-axis CNC machine by LS Manufacturing

How Can Complex Curved Surfaces Be Formed In One Step Using 5-Axis CNC Machining?

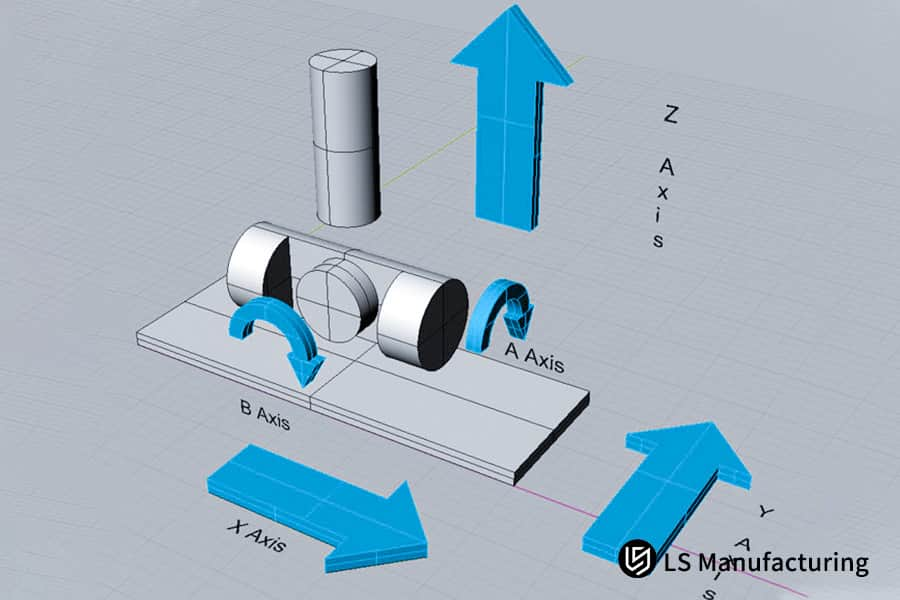

The 5-axis CNC machining principle will rely on the ability to position the cutting tool or the workpiece on two additional axes of rotation. This process demonstrates how 5-axis CNC machining works in practice. This process will make it possible for one to complete the machining process on complex shapes from various angles in a single setup, especially during complex surface machining.

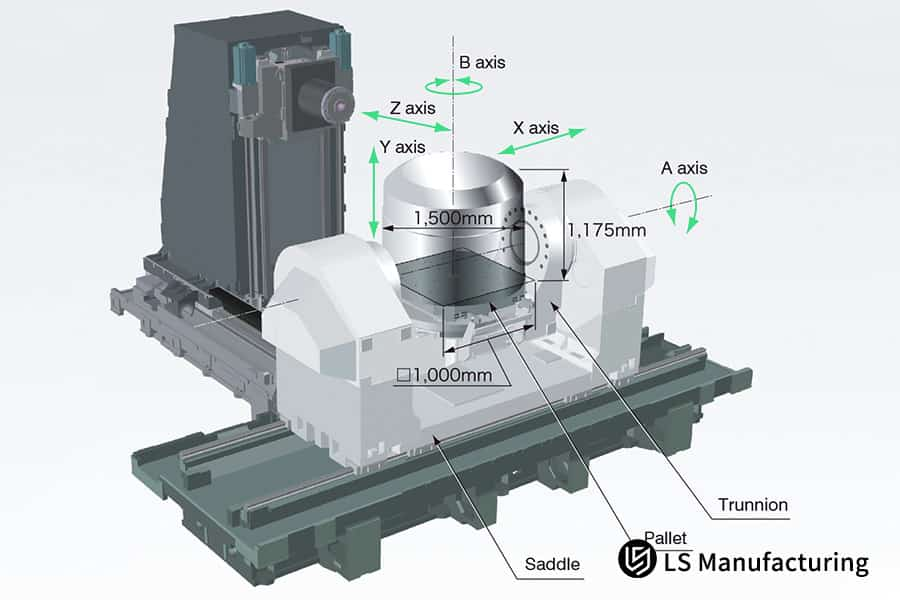

Mechanical Structures and Kinematics

There are various structures of machining systems, for example, rotary table or trunnion, swivel head, and so on. They involve the use of 5 axes. In trunnion mechanisms, turning or A axis and rotation or C axis of the job are done with the help of a cradle. The synchronized movement of these rotary axes with the linear X, Y, Z axes allows the tool to maintain optimal orientation to the complex surface machining, ensuring high-efficiency cutting and superior finish in a single operation.

Path Efficiency vs 3-Axis

Contrary to 3-axis machining, where positioning of various machining operations must be carried out in such a way that there is a lot of repositioning, 5-axis machining requires smooth movement of tools within the machining process. There are no stair-step movements in 5-axis machining. It allows easy access of the machining tool to the undercut and stepped walls. This is made possible by the machining process of the 5-axis CNC machining principle.

Error Reduction and Precision Gain

In this case, the key benefit attained is based on there being a single setup. This particular part of the setup being done in one clamp removes errors created through a number of setups. This directly translates to exceptional accuracy, often achieving positional tolerances within ±0.01mm, and perfect relative alignment of all features, a critical advantage for precision complex 5-axis surface machining.

Optimal Tool Engagement and Quality

The facility of adjusting either the tool or the workpiece helps in achieving dynamic titling and thereby helps in maintaining an optimal angle of cutting. This technique helps in utilizing short cutting tools and also prevents vibration. This aspect of the 5-axis CNC machining principle is vital for producing high-integrity parts via one-piece molding technology.

In conclusion, with the combination of these two rotational axes, the 5-axis CNC machining system achieves completely unobstructed access to the workpiece. This fundamental capability enables the realization of highly intricate complex surface machining and facilitates the advanced one-piece molding technology, which are essential for manufacturing high-precision components in a single, efficient setup.

Which Technical Parameters Directly Affect The Accuracy And Cost Of 5-Axis Machining?

Although the analysis and evaluation procedure of 5-axis machining center has been going on, the question of general technical cost analysis emerges as a matter of immense relevance and importance. It becomes even more important in case of complex part 5-axis machining. Machine tool performance indicators that help in directly influencing part performance, along with capital cost, include a lot of these parameters.

| Parameter Category | High-Performance Config | Standard Config | Primary Impact |

| Positioning Accuracy | ±0.001 mm | ±0.005 mm | Final part tolerance, setup complexity |

| Repeatability | ±0.0005 mm | ±0.002 mm | Batch consistency, scrap rate |

| Max Spindle | Speed 30,000+ rpm | 15,000 rpm | Surface finish, material options |

| Tool Capacity | 120+ tools | 24 tools | Unattended operation, flexibility |

On a concluding note, it is required to make a comparison concerning purchase pertaining to investment needs. 5-axis machining accuracy parameters in terms of the submicron level possess very expensive purchase costs and very low usage cost. In addition to that, there is a need to make a comparison concerning all machine tool performance indicators.

How Do 5-Axis Programming Strategies Affect Machining Efficiency And Pricing?

The optimal 5-axis programming strategy has been observed to be a significant variable irrespective of the capability of the machine. It has been observed to influence directly the cycle time, tool life, and final machining efficiency optimization. The variables encompassing the CAM software programming strategy and its variables contribute towards the final CAM programming cost of the machined components. This eats into a considerable amount of engineering time in programming complex machined components.

| Programming Factor | High-Efficiency Strategy | Common Approach | Impact on Process |

| Toolpath Type | Continuous 5-axis movement | 3+2 positional machining | Cycle time, surface finish |

| Cut Parameters | Optimized for tool & material | Conservative defaults | Tool wear, machining time |

| Collision Avoidance | CAM | Programmer check | Safety, programmer time |

| Simulation | Full machine simulation | Toolpath only | Risk reduction, setup time |

In general, there seem to be valid reasons for feeling that an investment in an efficient 5-axis programming strategy is of immense reward, thanks to its ability to 5-axis machining efficiency optimization. Although it entails an additional CAM programming cost, which also involves complex and high-tech software, one is enjoined to think that this strategy could be of immense potential regarding its ability to save time, thanks to its error-free nature and longer tool life. The quoting of jobs should also take into account programming complexities.

Figure 2: Supplier qualifications for high-precision CNC machining processes by LS Manufacturing

How To Assess The True Technical Capabilities Of A 5-Axis Machining Supplier?

It takes time to evaluate the qualified 5-axis CNC machining supplier. How assessing a 5-axis machining supplier evaluation is related to more than financial cost related to suppliers through a verification process of supplier capability for satisfying needs related to quality. To begin, for a supplier selection criteria to be considered qualified, they must meet these criteria.

Equipment and Certification Verification

Examine the machine tool supply data for equipment type and calibration data. Request the correct technical capability verification files, such as ISO 9001 files, and, more specifically, the accuracy test capability report for ISO 10791, specifically for the type of equipment investigated, as instrumenting will supply the primary data on the manufacturing capability.

Technical Team and Process Expertise

Find the technical competence of software developers. Deep technical know-how of the 5-axis machining supplier evaluation needs know-how of software used for computer-aided machining, know-how of writing a post-processor, & know-how of writing a process plan for Difficult-to-Cut materials.

Portfolio and Case Study Analysis

In this case, you will be required to carry out an analysis of a case study that entails similarities with regard to sophistication of components. This entails an area of knowledge that ought to be an indicator of a good supplier and also be the case study of their years of superiority. It would be an indication that you would offer proof for the statement that you make with regard to criteria for suppliers.

Test Part and Practical Validation

The starting point of this process is test part and practical validation. The first and most immediate requirement is consequently test part. Thus, test part is very challenging and has to be machined. Secondly, there is involvement of displaying the final test part to the supplier. Therefore, machining of the final product is done to show expertise in finished products.

In substance, for a 5-axis machining supplier evaluation includes a complex document audit, knowledge pool jointly, credentials in terms of performances, and testing. You can be sure that your supplier has the skills required for creating precise parts if you comply with all supplier selection criteria above.

Transparent Breakdown Of 5-Axis Machining Quotes: What Are The Core Cost Items?

It is essential to dissect 5-axis machining quote breakdown. One ought to familiarize oneself with all relevant data regarding 5-axis CNC machining quote or else it will become nugatory to make an opinion regarding its reasonableness. In addition, price clarity will allow consumers to understand what they get for their price, and there will be no necessity for the justification of price through price value instead of price points.

- Machine Time and Capital Depreciation: This would be revealed to be a prime cost and would be evaluated on the basis of hourly economic cost. This would consist of details such as “the price of an accurate machine, its repair, and overheads.” To come up with an exact estimation of the 5-axis machining quote breakdown, it becomes necessary to merge machine time and economic cost on the basis of machine operating levels.

- Engineering and Programming Labor: This refers to the accurate pricing elements of CAM programming, tool path simulation, and post-processing. For complex components, programming time may range from 2-8 hours or more for complex components. It is openly provided by the supplier as a separate line item because of the engineering that must be completed before material is machined.

- Materials and Tooling Consumption: These would be the cost of material blanks. There would also be a breakup cost of materials. There would also be the wear and tear that results from the use of specific tools during the process of doing 5-axis machining. There would be the cost of tooling.

- Quality Assurance and Post-Processing: This will include the time and equipment for in-process inspection, final inspection with the CMM machine, and any necessary second operations, including deburring or additional surface finishing. To break this process down means that quality is placed on the table, and all accurate pricing elements are made clear.

To achieve cost transparency within 5-axis machining, the value-added aspect related to the decomposition of cost value has to be applied. detailed 5-axis machining quote breakdown that includes machine time, engineering, material, and verification can provide customers with a clear understanding, which can justify the spending and ensure all the accurate pricing elements are included, helping in creating a better business relationship.

Figure 3: Illustration of 5-axis CNC machine tool movements by LS Manufacturing

LS Manufacturing Aerospace Industry: 5-Axis Precision Machining Of Titanium Alloy Brackets For Satellites

The LS Manufacturing success case serves as a strong example of the major impact advanced machining can have in overcoming high-level challenges in the industry. The manufacturing of a particular satellite component that was being deemed crucial to fulfill the mission requirements of the particular aerospace firm was proving hard for an aerospace industry leader.

Customer Challenge

Besides this, the customer had the particular requirement for this bracket to be produced with a lightweight and strong material: a titanium alloy. Traditional machining, involving several operations, wouldn't have been able to handle such a tolerance requirement as +/−0.015mm for +/−0.015mm. Severe machining distortion and a low 70% qualification rate caused project delays and increased the costs, pointing out conventional aerospace parts machining difficulties.

LS Manufacturing Solution

The titanium alloy 5-axis machining that LS Manufacturing had developed was accomplished through a unique approach such as: There was an applicable custom-made 5-axis machining center applied, together with the relevant design for the fixture that encouraged stress reduction. Overall machining was meant to occur once without any occurrence of misalignment and warped error associated with the materials. This is taking into consideration the optimized machining process.

Results and Value

This is because the effect resulting from this phenomenon has a revolutionary nature. The quality rate of products has remarkably improved by 99.5% to ensure high-quality products. This is proof that we are technically capable of precisely machining products with the precision 5-axis CNC machining technique. As a result, the delivery cycle has amazingly reduced by 40%. This helped our client enjoy an amazing saving of over 800000 yuan annually.

Briefly summarized, the following LS Manufacturing success case will confirm that the specialized expertise in titanium alloy 5-axis machining overcomes core challenges while aerospace parts machining with high precision. By ensuring part integrity, maximizing efficiency, and bringing substantial economic value, LS Manufacturing proved to be a strategic partner for advanced aerospace manufacturing.

If you have similar requirements for complex parts, please click to consult and get the quotation for the 5-axis machining solution.

Why Can LS Manufacturing Provide The Most Accurate 5-Axis Machining Quotes?

With LS Manufacturing competitive pricing, it is true to say that in its process it neither gives price estimates but only gives an estimation through the methodology involved in engineering. Our reputation as a 5-axis machining expert is based on transparent process control and data-driven analysis, which directly enables our accurate pricing guarantee to clients.

- Precision Equipment Foundation: We have a cluster of 5-axis machining centers of German origin in our workshop. This standardized, high-performance platform provides predictable and consistent machining cycles. As the first critical input into our cost model, this stability enables us to make reliable time calculations rather than guesses, which forms the bedrock of our accurate pricing guarantee.

- Engineering Team Expertise: Excellent passion for the change in part geometries to optimum manufacturing solutions by more than 20 process engineers with in-depth, strong, and intense devotion-qualifies this as the engineering team with impressive knowledge about toolings and specialty knowledge on material behavior for complex parts. This is human expertise and the core trait that defines a true 5-axis machining expert. Costly inefficiencies have been upfront eliminated.

- Standardized Quoting System: In order to please our valued clients with the proper quotes, we in reality make use of our quotes system whereby various factors for quotations, such as machine time, programming time, materials, tooling, and quality control taken into consideration. The quotes system does not require guesswork on the quotes but ensures correct LS Manufacturing competitive pricing.

- Real-Time Cost Model: The quotations proposed to our clients have been designed with the background of implementing a cost model that takes into consideration all real-time factors pertaining to the rates of the depreciation of machinery, the rate of tooling, and material costs. Our cost model has been updated on a continuous basis with previous project inputs to ensure that the level of accuracy will be 95%+.

In other words, LS Manufacturing competitive pricing is a result of investment in technology, specialized expertise, and systematic processes. That's why we can offer an accurate pricing guarantee-because we have cost analysis from the position of being 5-axis machining experts that are capable of controlling variables from the first CAD file all the way to the final inspection report to make sure every project is treated fairly and predictably.

What Key Technical Information Is Needed To Obtain An Accurate Quote?

To get you a quote fast and accurately, clear and complete information is a priority. Our main foundation in technical document preparation documentation gives a direct impact on the speed and reliability in costing analysis. Following a structured quotation guide for submitting all accurate quotation data requirements eliminates guesswork and leads to a more precise proposal.

- Comprehensive Design Data: Full 3D model in a generic form like STEP/IGES, and corresponding 2D drawings. Geometries are supposed to be defined in 3D models. In 2D drawings, definition of critical sizes and geometric tolerancing is given. It is our most important source of knowledge on machining strategy and hence the most critical job of your technical document preparation.

- Material and Specification Details: Clearly state the full material grade, standard, and preferred supplier or required certification. Also, specify the initial blank size or form. The choice of material significantly impacts machining time, wear and tear, and cost; hence, details on this must be a necessary part of accurate quotation data requirements in order for any deviation from the budget estimate to be negated.

- Quality and Post-Processing Requirements: This is where critical tolerance requirements, surface finishes, and other potential post-process requirements like heat treating, anodizing, and/or plating may be called out. It is here that one might also find how services such as secondary process services may be needed. Quoted costs for such details are very significant.

- Logistical and Ancillary Information: Include the required annual production volume, target piece price, and any specific packaging or delivery needs. Volume affects fixture strategy and production planning. Sharing these business parameters, as suggested in a thorough quotation guide, enables us to propose the most cost-effective manufacturing solution for your needs.

When it comes to collaboration and working together for an outcome, communication is key. As you ensure that all 5-axis accurate quotation data requirements as indicated within this quotation guide, you fundamentally provide an important requirement for your team to achieve exactly what you want done within your feasibility analysis. When working on compiling a technical document preparation, it helps ensure an exact analysis of 5-axis CNC machining quotation done within your project.

Figure 4: Challenging geometries produced with 5-axis CNC machining by LS Manufacturing

How Do I Start My 5-Axis Machining Project And Get An Instant Quote?

We offer 5-axis CNC machining services that make it easy for you to initiate projects seamless integration. In order to make our cooperation process guide simpler for you, we provide seamless ease of transition from your idea to proposal to enable you to readily get real-time quotes and easily begin your 5-axis machining project launched.

- Document Submission Online: First, submit your whole tech package-be it 3D models, drawings, and specifications-through some web-based document-submission portal. This would make it further clear as to how to get a CNC machining quote. This immediate submission triggers our 24-hour response protocol, allowing our engineering team to start the review process without delay, which is the first step to get real-time quote.

- Technical Feasibility Review: In a matter of hours, an experienced engineer is assigned to review manufacturability. We review geometry, tolerances, and materials for technical issues-in some cases including free preliminary technical consultation to make your design more manufacturable at no cost to you before final cost analysis.

- Process Planning & Quotation: Following this is our team of experts, identifying the best machining process and working out the tooling workflow. Our detailed process goes directly into our standardized system of costing. You shall be able to see a detailed breakdown of our quote so that you know all cost drivers before your 5-axis machining project launched.

- Confirmation & Project Launch: A discussion related to your proposal and modifications will be done accordingly. Thereafter, based on your confirmation, a scheduling of your project is done. All the paperwork, which relates to the process, gets formalized, and a project manager is assigned in order to ensure a smooth start right from the cooperation process guide.

In the end, our cooperation process guide leads to no uncertainty. From the online submission to the quote proposal, we guarantee you clarity and speed to get real-time quotes. Our fast-track system ensures that you will be able to make informed choices and kick-start the 5-axis machining project launched to transform your design concept into a machined masterpiece.

FAQs

1. What is the MOQ for 5-axis machining?

From prototyping to large-scale production services for production, all services offered have commenced right from the perspective of production. All orders placed have been done with services that can meet all the different demands, based upon levels of research and development, sample production, and pilot production.

2. Does the quotation include the charges for inspection?

The quotation for price will also consider the first article inspection cost. The bulk orders will also include the costs of sampling and final inspection aimed at ensuring that control of the process is conducted from the beginning to the mass production stage concerning the cost of inspection.

3. What is the maximum workpiece that can be machined?

Machining maximum moving area in 5-axis machine: 1200×800×500mm. Yet, it shall be reviewed and decided taking into consideration the structure of it and type of processing. Depending upon different WorkPiece processing, it may differ.

4. In what ways can the machining accuracy be maintained constant?

Together with the on-line measurement system, it can be achieved for real-time monitoring of the entire process of machining, and then combined with equipment accuracy calibration, process parameter verification, and accuracy control based on batch machining.

5. Are material certification reports available?

These could be the certification papers of original materials obtained from manufacturers or test papers for materials, grade of materials, physical properties, etc.

6. Does the variation in design affect the price?

Further, an updated quote based on the timeline for the client will also be provided, but when it comes to design changes, it will be left at the discretion of our engineers to decide on what type of design change has been implemented on the drawings in terms of processes and cost incurred within 2 hours.

7. Under normal conditions, how many hours does it take for a mother to deliver?

Sample delivery time: 5-7 working days. The time for mass production: 2-3 weeks. Depending on items. The exact time will be established after considering the complexity level of the particular item production process.

8. How are quality issues resolved?

For quality issues related to the product, we use a first-piece inspection system. Should the root cause be in the processing quality, we will reproduce them for free, as well as upgrade the process to maintain customer schedules and quality without being impacted by the problem while taking the right responsibilities.

Summary

With a deep understanding of the principles and costs involved in 5-axis machining, it will be possible to make a better purchase decision. Among the very best manufacturers of 5-axis CNCs in the market, LS Manufacturing with advanced technology and experience offers the most authentic quotes for each machining procedure.

There is no better way to get started immediately than to upload your part files today, and our team of 5-axis machining experts will get you a complete process analysis and quote in 2 hours or less! Avail yourself of a free DFM analysis report today, and consult with our team!

Mitigating mass production risks associated with complex curved surfaces and unibody molding. Get a professional solution based on five-axis machining now.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.