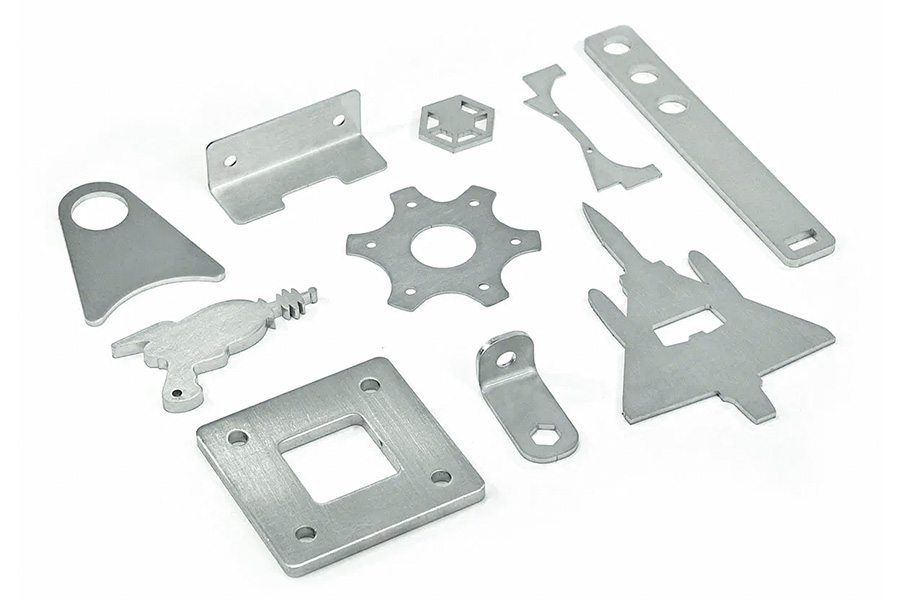

In the manufacturing industry,stainless steel sheets are used in a wide range of applications. Its cutting quality plays a decisive role in the precision and appearance of the product. Laser cutting technology has become an excellent choice for stainless steel processing due to its high efficiency, precision and small heat-affected area. However, there are many kinds of laser cutting equipment on the market, which is dizzying, how to choose the most suitable model for stainless steel plates? Next, this article will talk about how to choose the idealstainless steel laser cutting machinefor you from a number of key aspects.

What Defines a Stainless Steel Laser Cutter?

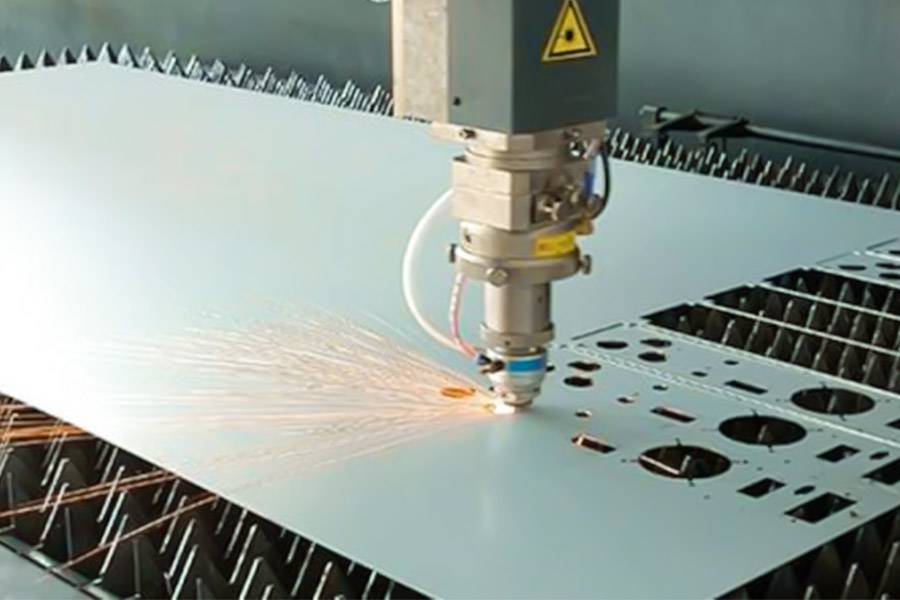

Thestainless steel laser cutting machine uses a high-energy laser beamto irradiate the stainless steel plate, so that the plate can be quickly melted, vaporized, or reach the ignition point. At the same time, the melt is blown away by a high-speed air flow coaxial with the beam to complete the cutting task. Thiscutting method has high precision and high speed, narrow cutting seam, small heat-affected area, and very smooth cutting surface, which is especially suitable for the processing of metal materials such as stainless steel.

Analysis of core indicators

When choosing a stainless steel laser cutting machine, there are several key indicators to focus on.

1.Laser type

| Index | Fiber laser (1μm) | CO₂ laser(10.6μm) |

|---|---|---|

| Absorptivity | 40-50% (stainless steel) | 5-15% (stainless steel) |

| Cutting efficiency | Sheet speed advantage (3 mm or less) | Plate quality advantage (>6mm) |

| Photoelectric conversion efficiency | 25% | 10% |

| Applicable Materials | Metal-based (cuttable copper) | Metallic or non-metallic |

| Running costs | Low (Energy Consumption + Maintenance) | High (gas consumption + maintenance) |

Suggestions for selection:

- Forprecision machining of thin plates(less than 3mm thick), fiber lasers are preferred.

- For thick plate processing (thicknesses greater than 10mm), consider using high-power CO₂ lasers.

- If you need to cut copper, you have to use a fiber laser.

2.Power requirements

Laser power has a significant impact on cutting ability. When cutting stainless steel plates, different thicknesses have the following requirements for power:

- Cutting 1mm thick stainless steel plates requires a laser power of not less than 500W.

- Cutting 10mm thick stainless steel sheets requires a laser power of not less than 6,000W.

- Choosing the right laser power can not only ensure cutting efficiency and quality, but also avoid waste of energy and reduce equipment loss.

3.Cutting accuracy standard

According to ISO 9013:2018:

- Positioning accuracy: The positioning accuracy of the X/Y axis is ±0.03mm.

- Repeatability: up to ±0.02mm.

- Roughness of the cutting surface: Ra does not exceed 6.5 μm when nitrogen is used.

- Perpendicularity: When thethickness of the plateis less than or equal to 10mm, the verticality deviation does not exceed 0.1mm.

4.Precision Assurance Technology:

- Linear motor drive system with acceleration of 2G and beyond.

- Closed-loop control servo system, response frequency not less than 1kHz.

- Auto-focus cutting head, dynamic response time less than or equal to 50ms.

What is the working principle of stainless steel laser cutting machine?

Stainless steel laser cutting machines rely on a high energy density laser beam to cut stainless steel with precision, and the workflow is as follows:

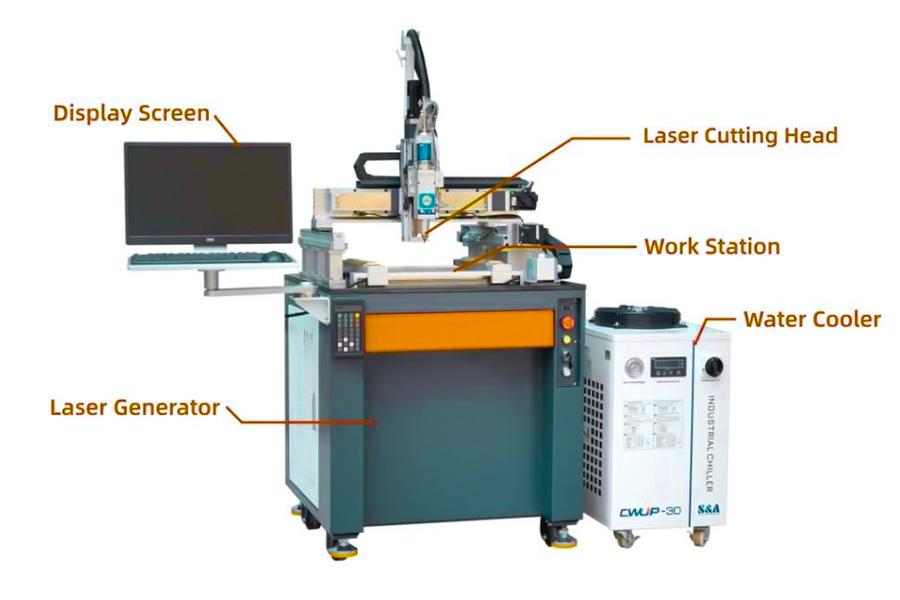

1.Laser generation

The laser is the core, producing a high energy density laser beam. It has good directionality and monochromaticity, and the energy energy is highly concentrated, providing an energy basis for efficient cutting, and continuously outputting a stable laser to promote thecutting process.

2.Beam focusing

Through the optical system composed of mirrors and lenses, thelaser beam is focused into a very small spot, and the energy density is greatly improved. The focused laser beam is extremely hot enough to melt or even vaporize stainless steel instantaneously, and the optics are precisely calibrated to ensure that the laser beam falls precisely at the cutting site.

3.Heating of the material

The focused high-energy laser beam irradiates thesurface of the stainless steel plate, the plate quickly absorbs light energy and converts it into heat energy, the temperature rises sharply to the melting point or boiling point in a short time, the material begins to melt or vaporize, and the laser energy interacts with the material to change its physical state.

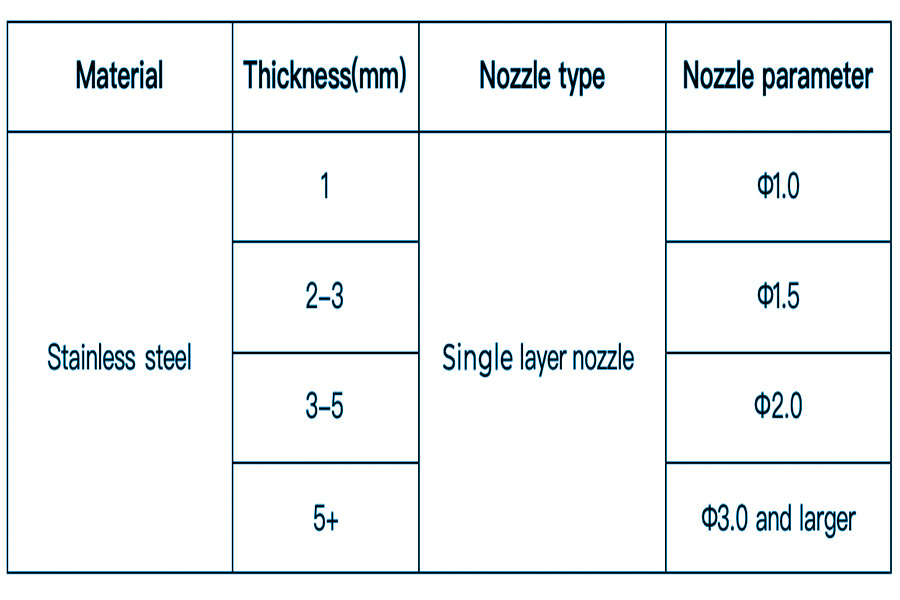

4.Material removal

After stainless steel is melted or gasified, it forms a melt or oxide, and the auxiliary gas (nitrogen, oxygen, etc.) is blown into the cutting area at high speed through a special nozzle, blowing these substances away and forming a slit. Oxygen can increase the cutting speed through oxidation reaction, which is suitable for scenarios with high speed requirements; Nitrogen, as an inert gas, can protect the cutting surface from oxidation, and is mostly used in cases where the surface quality is required to be high,depending on the material characteristics and cutting process.

5.Motion control

Numerical control (CNC) is essential to precisely control the laser heador table to move along a preset path to achieve complex shape cutting. The system has high precision and fast speed, ensuring the accuracy of the cutting path and improving thecutting efficiency, the operator inputs the cutting pattern and parameters, and the system automatically controls the movement of the parts to complete the precise cutting.

6.Cool and clean

At the moment when the cutting is completed, due to the good heat dissipation of the stainless steel and the natural cooling of the environment, the plate is quickly cooled down, and the cutting edge is smooth and flat.Laser cutting precision is high, the heat affected zone is small, and in most cases, the cut material does not need to be reprocessed, and can be directly used for subsequent processing or use, improving production efficiency and reducing costs.

Which Laser Type Cuts Faster?

Instainless steel laser cutting, fiber laser cutters typically cut faster than CO₂ laser cutters. The following is an analysis of the advantages of fiber laser cutting machines in terms of cutting speed:

The speed advantage of fiber laser cutting machine

Reflectance treatment: Fiber lasers penetrate stainless steel (40%) up to 3 times more efficiently than CO₂ lasers. This means that when cutting stainless steel, the fiber laser can penetrate the surface of the material more effectively, improving the cutting efficiency.

Speed comparison: Taking a 1mm sheet as an example, the cutting speed of the fiber laser cutting machine can reach 25m/min, while the cutting speed of theCO₂ laser cutting machineis only 8m/min. This data directly shows that in the same thickness of stainless steel plate cutting, the speed of the fiber laser cutting machine is significantly faster.

Limitations of CO₂ laser cutters

Yellowing and oxidation of the cutting surface: When cutting stainless steel with a thickness greater than 8mm, the cutting surface of the CO₂ laser cutting machine is prone to yellowing and oxidation. This not only affects the quality of the cut, but can also cause inconvenience to subsequent processing.

| Index | Fiber lasers | CO₂ laser |

|---|---|---|

| Speed advantage | Sheet (≤6mm) | Plate (>8mm) |

| Cut quality | Smooth cut(Ra≤6.5μm) | Rough cut(Ra≥25μm) |

| Oxidation problems | No oxide layer | Thick plates are susceptible to yellowing and oxidation |

| Running costs | Low (Energy Consumption + Maintenance) | High (gas consumption) |

| Applicable Materials | Metal-based (cuttable copper) | Metallic or non-metallic |

Selection suggestions:

1.Option fiber laser:

- Processing stainless steelwith thickness ≤ 8mm

- Requirement of high-precision, non-oxidized cuts (such as precision parts, medical equipment)

- Need to cut copper or highly reflective materials

2.Consider CO₂ laser:

- Processing stainless steel with thickness > 12mm (subsequent grinding required)

- Need to cut non-metals (such as wood, plastic) at the same time

- Budget is limited and the cut quality requirement is not high

How Does Material Thickness Affect Choice?

In stainless steel laser cutting, thethickness of the material is the key to determining the selection of cutting equipment.Stainless steel plates of different thicknesses have different advantages for different adaptation equipment.

| Thickness range | Recommended equipment | Key parameters | Cutting method |

|

Sheet (0.5-3mm) |

500-1,500W fiber laser | Wavelength 1μm, absorption rate 35-40% Photoelectric conversion efficiency 25% |

Nitrogen protects cutting |

|

Medium & Heavy Plate (4-15mm)

|

4,000W+ fiber laser | Oxygen assisted, speed increased by 50% Spot diameter0.1-0.3mm |

Oxygen reactive cutting |

|

Extra Thick Plate (>15mm) |

Disk lasers of 6kW or more | Beam quality M²<1.3 Penetration depth > 25mm |

High brightness through cutting |

What Cooling System is Critical?

In laser cutting machines, water-cooling systems are essential for high-power equipment. Here are the key requirements and benefits of a water-cooled system:

Key requirements:

- Water flow: at least 4 liters per minute per kilowatt of power to prevent the lens from overheating and deforming, andto ensure cutting accuracy.

- Water temperature control: It is necessary to maintain accurate control of ±0.5°C to avoid condensation fog affecting the stability of the optical path.

Advantage:

- Efficient heat dissipation: The circulating water takes away the heat to ensure the stable operation of the equipment, and the heat dissipation efficiency is higher than that of the air-cooled system.

- High stability: Precise temperature control, reduce performance fluctuations, andimprove the stability of cutting quality.

- Extended life: Effective heat dissipation, reduce thermal stress, and prolong the life of equipment.

Limitations of air-cooled systems:

- Limited power range: only for small power devices up to 1kW.

- Low heat dissipation efficiency: It is difficult to dissipate large amounts of heat quickly.

Application Scenarios:

- High-power cutting: The water-cooled system ensures the stable operation of the equipment under high loads.

- Precision machining: Provide a stable environment and improve cutting accuracy.

Thewater cooling system is indispensable in high-power laser cutting machinesto ensure efficient heat dissipation and stable performance.

Which Safety Standards Must Be Met?

Tomeet these safety standards, you need to start from equipment design, operating specifications, personal protection, and environmental management, and the following is a detailed introduction:

Laser safety aspects

To comply with the IEC 60825 - 1 Class 1 protection class standard, it is necessary to ensure that thelaser equipment has emission control measures, safety interlocks, clear laser safety class markings on the equipment, and that the operator is trained in laser safety.

Exhaust gas treatment

In accordance with the EN 1093-3 metal dust emission standard, it is necessary to have an efficient and well-sealed exhaust gas collection system, use suitable exhaust gas treatment equipment, and install emission monitoring equipment to ensure that the emission standards are met.

Operational protection aspects

Equipped with wavelength special protective glasses, its optical density should reach OD7+, and the operator should wear it in a standardized manner throughout the operation.

Provide a fully enclosed working cabin, which can effectively isolate more than 90dB of noise, and the working cabin should have a good sealing structure and sound insulation materials, and install noise monitoring equipment.

How to Select the Ideal Laser Cutter for Stainless Steel Sheets?

1.Define your needs

- Material thickness:Fiber laser is selected for thin plate (1-6mm), andCO₂ laser or high-power fiberis considered for thick plate (>6mm).

- Accuracy requirements:fiber laser (small spot) for precision parts, and ordinary processing can balance efficiency and cost.

- Production scale:Automation functions (such as autofocus, intelligent nesting) are required for large quantities.

2.Comparison of device types

- Fiber laser:suitable for thin plates, high speed, maintenance-free, but with a decrease in the quality of thick plates.

- CO₂ laser:Stable cutting of thick plates, but high energy consumption and maintenance.

3.Key parameters

- Power:Estimated by thickness × factor (40-60) (e.g. 3000-3600W for 6mm).

- Focus:The thin plate focuses on the surface, and the thick plate is appropriately lowered.

- Gas:oxygen to improve efficiency, nitrogen to ensure quality.

4.Cost & After-sales

- Initial investment:Fiber optic equipment is expensive but saves power in the long run, CO₂ is cheap but has many consumables.

- Service:Choose a brand with fast response and sufficient spare parts.

Summary

Choosing a stainless steel laser cutting machinemust follow the logic of "demand drives parameters, and parameters determine equipment". It is recommended to verify the performance of the equipment through trial cutting, and give priority to suppliers with technical iteration capabilities. In the future, with the popularization of 10,000-watt lasers, the efficiency of thick plate cutting will be further improved, and companies can flexibly select models based on their own development plans.

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.pleaseContact usLearn moreEFOrmation.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.What laser intensity is required to cut stainless steel?

The laser intensity (power) required to cut stainless steel depends on the thickness of the stainless steel and the cutting quality requirements. Generally speaking, the power can be around 1600W for cutting 2mm stainless steel; the power may need to reach 2200W or higher for cutting 3mm stainless steel. In practical applications, it is also necessary to adjust according to parameters such as cutting speed, focus position, and gas type.

2.Can CO2 laser cut stainless steel?

Yes. CO2 laser cutting machines can stably cut stainless steel, especially suitable for cutting carbon steel within 20mm, stainless steel within 10mm, and aluminum alloys below 8mm. The wavelength of CO2 laser is 10.6um, which is also suitable for cutting non-metallic materials.

3.How to choose a laser cutting machine according to the thickness of the stainless steel plate?

The thickness of the stainless steel plate is an important reference factor for selecting the power of the laser cutting machine. Generally speaking, for cutting stainless steel plates below 2mm, a laser cutting machine with a power of about 1000W can be selected; for cutting stainless steel plates of 3-6mm, the power needs to reach more than 2000W; for cutting thicker stainless steel plates, a higher power device needs to be selected.

4.How to balance cutting accuracy and speed?

Cutting accuracy and speed are two important performance indicators of laser cutting machines. In stainless steel plate cutting, if the cutting accuracy is high, such as the production of fine crafts, you should choose equipment with high precision and good stability; if you pay more attention to cutting speed to improve production efficiency, you can pay attention to the cutting speed parameters of the cutting machine. In practical applications, it is necessary to find a balance between accuracy and speed according to specific needs.

Resource

Effect of laser cutting parameters on surface quality of low carbon steel (S235)