So what is CNC milling? By delving into how CNC milling technology establishes a competitive advantage for your products, we will demonstrate how LS Manufacturing's "Technology-Process-Quality" iron triangle system provides "zero-defect" precision manufacturing solutions, systematically eliminating uncertainties throughout the supply chain and ensuring ultimate reliability from design to delivery. To save you time, here’s a quick overview of the core conclusions.

CNC Milling Full-Text Quick Reference Table

| Module Classification | Core Content |

| Basic Definition | A manufacturing process that employs digitally controlled milling cutters to precisely cut workpieces. |

| Key features | High accuracy, high reproducibility, and high degree of automation. |

| Types of equipment |

CNC milling machines, each with various degrees of freedom: 3-axis, 4-axis, and 5-axis. |

| Applicable Materials | It can process several types of CNC milling materials, but is not limited to metals, engineering plastics, and composite materials. |

| Process Capabilities | Capable of complex operations such as plane milling, contour machining, and curved surface machining. |

| Accuracy Grade | Maximum machining accuracy up to ±0.01mm, surface roughness Ra0.4μm. |

| Tool System | Equipped with special tools, such as end mills, face mills, and ball end mills. |

| Application Areas |

Widely used in precision manufacturing industries including mold making, aerospace, medical, and automotive. |

The digital program control makes a breakthrough in precision machining through the top-level CNC milling technology. With superior machining precision, stable repeatability, and a high degree of automation, this technology will continue to be indispensable as part of the core role in modern manufacturing. The extensive CNC milling applications across aerospace, medical devices, automobile manufacturing, and precision molds demonstrate its capability to provide solid, reliable technical support, and development impetus for precision parts manufacturing in these demanding industries.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing has accumulated fifteen years of technical accumulation in CNC milling, representing the high-precision processing of turbine blades for the aero-industry, manufacturing of implants for bone replacement in medical devices, and processing of base components for precision instruments. These highly successful practices have become a solid foundation for this guidebook.

We have developed unique insights into material analysis, toolpaths, and parameter optimization based on project experience. With production strictly following the Occupational Safety and Health Administration(OSHA) safety standards and the US Environmental Protection Agency(US EPA)'s environmental requirements, safe production and green manufacturing are realized through standardized operation procedures and waste disposal, thereby assuring service quality.

Based on the accumulation of experience in machining tens of thousands of complicated workpieces, a set of systems for CNC milling technology was established, covering key technology such as high-temperature alloy machining and thin-walled part control. This handbook condenses this practical experience and provides the industry with a practical and reliable technical reference.

What Are The Primary Advantages Of CNC Milling?

While CNC milling technology includes traditional machining precision and efficiency, its strategic value far exceeds that. The fundamental value of it lies in the fact that it achieves controllable manufacturing throughout the whole process. It is this digital characteristic that makes it the cornerstone of modern precision manufacturing, constituting an important advantage of precision CNC milling. Major benefits are specifically reflected in the following three dimensions:

Process Predictability

Quality Consistency Assurance

Complex Process Integration Capabilities

The 5-axis linkage and other advanced technologies enable the high-precision machining of complex spatial surfaces in one step, which significantly reduces the clamping time for workpieces and simplifies process flows. By completing multiple operations in a single setup, the need for complex fixtures and multiple machine transfers is eliminated. In addition, this integrated approach will not only improve production efficiency but will further enhance the controllability of final quality manufacturing with a marked reduction in accumulative errors caused by repeated repositioning.

The essential benefit of precision CNC milling, therefore, is the certainty afforded by controllable manufacturing. It converts traditional experience-based machining into a modern engineering system that is data-driven, predictable, and reproducible. LS Manufacturing, through its comprehensive digital management system, translates this advantage into stable quality output and supply chain reliability for its customers.

How To Plan The Optimal CNC Milling Process?

- Collaborative Design for Manufacturability (DFM): In our domain, even before programming, our engineers already intervene at the design phase to review the manufacturability of the parts in terms of machining. The adjustment in corner radii reduces the need for nonstandard tools, and optimization of wall thickness transition controls deformation-clearing obstacles for subsequent CNC milling process optimization right from the outset.

- Intelligent CAM Programming and Virtual Simulation: With intelligent CAM software, efficient toolpaths are generated and virtually simulated for the full process according to the DFM-optimized model. This step can predict and avoid interference and collision risks in machining by 100%, hence guaranteeing that the program will be correct the first time it is run, with savings in material and time that would normally be wasted in traditional trial-and-error methods.

- Big Data-Based Cutting Parameter Library: We do not apply fixed parameters uniformly across all machines, but instead construct a dynamic parameter library based on extensive historical machining data. By systematically optimizing the three core cutting elements for specific material-tool combinations, we maximize metal removal rates while ensuring tool longevity, thereby directly increasing machining efficiency by more than 20% and significantly enhancing production economy.

The LS Manufacturing methodology embodies the CNC milling process optimization by design, programming, and execution. Using forward-thinking design and driving decisions with data will convert traditionally experience-based "skills" to stable, replicable "science." That will in turn enable customers to achieve predictable delivery times, controllable costs, and reliable quality.

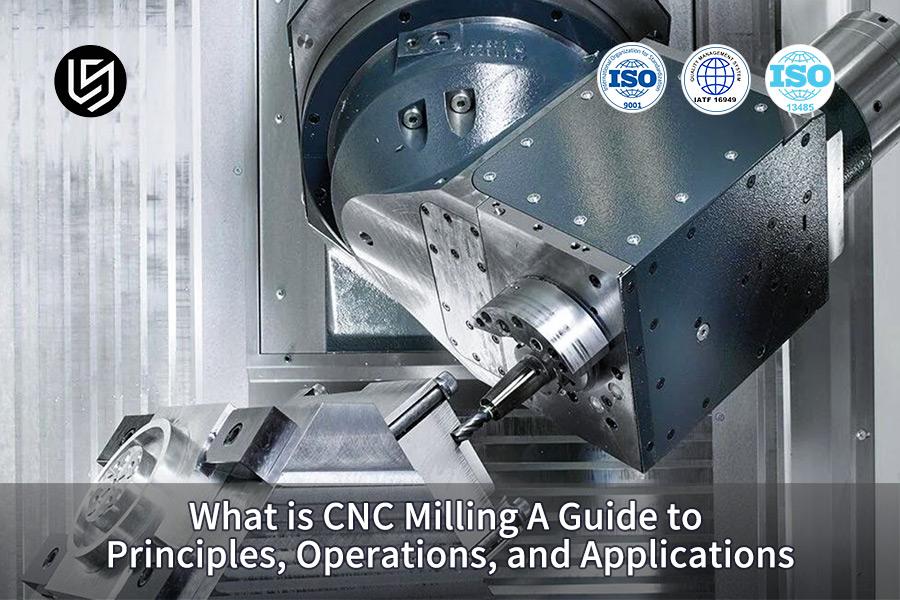

Figure 1: A modern CNC milling workshop currently in full operation by LS Manufacturing

3-Axis, 4-Axis, Or 5-Axis Milling? How To Choose?

Choosing the appropriate type of CNC milling is all about finding the right balance among machining cost, efficiency, and the complexity of the process. Different numbers of axes determine parts geometric handling capability and machining efficiency, while the value of 5-axis CNC milling is especially and can efficiently complete high-precision machining of complex spatial surfaces. For clarity, the table below will briefly compare the characteristics of the three machining methods:

| Machining Type | Motion Characteristics | Typical Applications | Relative Cost |

| 3-Axis Milling | Three linear axes are linked (X/Y/Z) | Planar contours, cavities, simple curved surfaces | Lowest |

| 4-Axis Milling | Adds one rotary axis-usually the A-axis | Cylindrical surface features, circumferential structures | Medium |

| 5-Axis Milling | Three linear axes plus two rotary axes linked | Complex spatial surfaces, impellers, irregular structures | Highest |

Simply put, the key to the selection of the type of CNC milling lies in matching geometric complexity and precision requirements of a part. For those with deep cavities, oblique holes, or complex curved surface features, 5-axis CNC milling realizes its value: it can complete multi-face machining in one setup without repeated positioning error and thus guarantees high accuracy and efficiency. Equipped with state-of-the-art five-axis machining centers and professional process technology, LS Manufacturing offers cost-effective solutions for complex parts.

Medical CT Equipment Base: How Does LS Manufacturing Overcome Complex Flow Channels And High Flatness Requirements?

Client Challenges

Internally, the new CT scanner of this leading medical equipment manufacturer is designed with a very complex cooling channel in its core base, while the outside surface serves as the mounting platform of many precision components. Traditional segmented machining methods cannot guarantee that these channels are completely sealed; besides, accumulated error due to repeated clamping on the mounting plane surpasses specifications, leading to overheating and image jitter that seriously affect the time-to-market.

LS Manufacturing Solution

We abandoned traditional processes and adopted a 5-axis CNC center for the integral machining of the base. A custom-designed long-shank milling tool was used to mill the complex three-dimensional internal channels in one go, guaranteeing a smooth tool-free surface; real-time detection by a machine probe compensated by milling controls flatness within 0.02mm constantly for each mounting surface.

Results and Value

The optimized base improved the device's heat dissipation efficiency by 40%, completely solving the image drift problem caused by thermal deformation. The product passed strict quality certification on the first attempt, reducing the time-to-market of the customer by two weeks and establishing its advantage in competition within the high-field-strength CT market.

This LS Manufacturing case study demonstrates that by applying the fundamental principles of CNC milling through well-designed process flows and rigorous process control, we can not only solve functional realization challenges in precision machining of medical parts, but also serve as a key driver for breakthroughs in core product performance. By ensuring seamless transition from prototyping to mass production, such methodologies guarantee exceptional accuracy and stability, ultimately achieving a qualitative leap in product reliability and market competitiveness.

Are you facing a similar challenge? Click to get your personalized milling solution!

What Are Three Things To Keep In Mind When Choosing A CNC Milling Supplier?

Equipment Strength and Process Adaptability

Whether the supplier has machining centers that match the complexity of your parts, such as 5-axis machines for complex curved surfaces, is just the foundation. True strength lies in the capability to equip dedicated cutting tools, fixtures, and cooling solutions for specific materials like titanium alloys and high-temperature alloys. This is fundamental to efficiently and stably accomplishing the machining.

Following is the soft power in process proactive DFM capability

Quality system assurance and traceability

There should be an appropriate quality control system in place at the supplier's end, such as ISO 9001 certification, and it should also be adequately equipped with inspection, coordinate measuring machines, and roundness testers. More significantly, they must be able to provide detailed end-to-end inspection reports so that the quality of each product is traceable and verifiable.

Put differently, choosing a scientific CNC milling supplier needs to look further than the surface price but comprehensively assess equipment, process, and quality systems. Be especially wary of suppliers not having proactive DFM collaboration-this is usually where project risk comes from in the trap described above. Equipped with comprehensive hardware and technical reserves, we provides standard DFM consulting, sparing no efforts to become a full-cycle manufacturing consultant for customers from design to mass production.

Figure 2: Operational overview of a precision CNC milling workshop by LS Manufacturing

Save On CNC Milling Costs With Design Optimization?

Cost reduction for CNC milling in a highly competitive market cannot rely on supply chain price reductions alone; it has to be supported by design for manufacturability (DFM) optimization right from the product design phase. The main strategy for achieving such a goal is successful design for manufacturability (DFM) optimization. This kind of optimization converts manufacturing constraints into cost advantages through forward-looking design decisions, which effectively reduces CNC milling costs. Our engineering team adds value to customers in the following specific ways:

Unified Corner Radius and Standardized Features:

For example, standardizing the various corner radiuses of a part into a single, unified dimension can significantly enhance machining efficiency. This design optimization minimizes the need for frequent tool changes during the CNC process, allowing for more continuous toolpaths and reduced idle time. As a result, this straightforward adjustment can improve production efficiency by more than 25%, directly lowering the time cost.

Optimized Wall Thickness and Rib Layout:

In addition, by optimizing the layout of ribs and designing gradual contour transitions, vibration and deformation during the machining of thin-wall parts are effectively mitigated. This structural enhancement improves the dynamic stability of the machining system and ensures more uniform material removal. This control measure reduces the scrap rate significantly from 8% to below 1%, thereby greatly lowering the quality cost and enhancing dimensional stability in CNC milling, which is crucial for meeting tight tolerance requirements.

Rationalized tolerances and simplified geometry:

It is essential to rigorously differentiate critical mating surfaces from non-functional surfaces and strategically relax the tolerance requirements for non-critical dimensions. For instance, increasing the tolerance on a non-mating internal surface from ±0.02 mm to ±0.05 mm can eliminate an entire finishing operation, thereby reducing the manufacturing cost by approximately 15% while still meeting all functional and performance criteria.

In a nutshell, DFM optimization will be the most effective method for reducing CNC milling costs. An engineering team from LS Manufacturing is your external support in giving specific design suggestions to convert your ideas into high-performance, cost-effective manufacturable solutions that give your projects an edge within the competitive market.

Five Factors Affecting CNC Milling Quotes

- Material Costs: The raw material procurement cost is fundamental, forming the baseline of any manufacturing budget. Different materials—aluminum alloys, stainless steel, and titanium alloys—are very different in price, and their machinability directly influences tool wear and machining time. This variability in workability dictates parameters such as cutting speeds and tool life, thereby acting as a key lever for the total cost of production.

- Machining Time: This geometric complexity of the part, such as the number of curved surfaces, deep cavities, narrow slits, etc., directly determines the difficulty in programming and actual machining time of machine tools. Complex geometries often require specialized tooling, multi-axis machining strategies, and significantly longer processing durations. Thus, it is the largest variable affecting cost fluctuations, as even minor design changes can lead to substantial differences in both programming effort and production time.

- Batch Quantity: The lot size varies greatly between the cost of single-piece sampling and that of small- and large-batch production. Quite logically, the larger the batch, the lower is the per-piece cost because of the programming and debugging of equipment. These initial setup costs, as with many others like fixture installations, tooling preparations, and first-article inspections, are spread over a much larger quantity of parts. Larger runs also provide more opportunity for superior machining parameters, further enhancing the cost efficiency by minimizing per-part material waste.

- Precision and Tolerances: More stringent tolerances of dimension and surface finish require machinery that is more precise, with much slower machining rates, and more complicated procedures of inspection. Besides raising the cost because of special tooling and longer cycle times, such specifications also drive up the manufacturing cost because of the need for more sophisticated measurement equipment such as CMMs or surface profilometers.

-

Post-processing and Packaging: All of the above-mentioned factors are necessary to achieve complete cost transparency in a quotation for CNC milling. We would recommend requesting a quotation with as complete technical information as possible, including material, post-processing, and quantity. LS Manufacturing will get back to you with clear and exact quotes calculated from standard time and material costs with no hidden charges attached.

All of the above factors should, in fact, be included to achieve cost transparency in a CNC milling machining quote. We would strongly recommend providing as comprehensive technical requirements as possible, including material specifications, dimensional tolerances, surface finish requirements, and annual production volume, when requesting a quotation. Later, LS Manufacturing will do a detailed analysis and get back with crystal clear and accurate quotations without attaching any hidden fees to it so that you have a thorough understanding of the costs involved in the project.

Figure 3: Precision CNC milling process schematic illustration by LS Manufacturing

Start Your Project With LS Manufacturing Today: Seamless Process

Starting a CNC milling project is not complicated. A proper and efficient LS Manufacturing collaboration process assures that your ideas flow effectively from drawing to finished product. We have standardized our collaboration path with the objective of keeping your management cost at a minimum, so you can focus on your core business. Our standard process includes five key phases:

- Submission and Initial Need Assessment: 3D drawings and technical specifications can be sent using our website or directly via email. Initial feasibility review by the engineering team and confirmation will be provided within 4 hours for quick response to your project needs.

- DFM analysis and optimization of solutions by professionals: As part of a detailed manufacturing feasibility analysis, the engineering team issues a comprehensive DFM report detailing specific cost optimization suggestions and process improvement recommendations arising from close work with you in order to finalize an optimal implementation plan.

- Quotation and Signing of Contract in a Transparent Manner: We will then present an itemized quotation concerning the solution that is being confirmed. All the cost items will appear clearly on the quotation. We confirm, then a contract can be signed immediately, to put it into production without delay according to the plan.

- Production Order and Progress Reports: After the start of production, you will be assigned a project manager who will provide you with progress reports with timely communication so as to ensure full control of the whole production process.

- Fully inspect the quality and deliver punctually: Before leaving the factory, all parts undergo strict quality inspection in accordance with established standards. Each batch has an accompanying inspection report in detail and is delivered to you safely on schedule as agreed.

The LS Manufacturing collaboration process is standardized to make it easy and reliable to start the CNC milling projects. From the very moment of submitting your requirements, full support by a professional team is guaranteed, each project having a project manager in charge to oversee every detail and maintain clear communication throughout the production cycle. That means on-time delivery, within budget, and to the highest possible standards of quality-a guarantee of seamless collaboration right from the initial inquiry to final delivery.

Figure 4: An organized presentation of precision CNC milling tool collections by LS Manufacturing

FAQs

1. What is the minimum order quantity at LS Manufacturing?

Can you support prototyping? We offer highly flexible manufacturing services, fully supporting everything from single-piece prototypes to tens of thousands of units in mass production. Whether it is the development and verification of a product or large-scale mass production, we are able to provide matching economical solutions to support your product lifecycle management.

2. How would you ensure that my product designs and drawings are absolutely secure?

We guarantee the security of your intellectual property: right from the start of our cooperation, we are legally bound by an NDA, while your design data enjoys the best security possible through an end-to-end encrypted file transfer and storage system at all stages.

3. Is 5-axis machining more expensive? In what scenarios can it save me money?

While the initial cost is rather high, there is strategic value that can be viewed through the savings 5-axis machining promises to yield over overall costs. It saves a lot on the total cost of manufacturing complex parts through the reduction of clamping operation times, combining the processes of machining, and improving the first-piece success rate drastically.

4. Do you do quality inspection reports during the machining process?

Of course, we can provide detailed reports according to your demands from first-piece inspection to full-dimensional inspection. All the inspection data will be recorded to guarantee traceability, transparency, and controllability of product quality during the whole process.

5. How can surface scratches and deformation be avoided while machining aluminum alloy parts?

The optimized parameters of cutting and path, special non-metallic tooling, and strict control of the process can well solve two common problems related to surface scratch and machining deformation in the industry, taking care of the characteristics of the aluminum alloy.

6. Does the quote include the surface treatment-anodizing?

The basic quotation usually consists of the cost for machining. We offer a one-stop CNC milling service. Surface treatments such as anodizing and sandblasting are listed separately, and you may include them or not. All costs are completely transparent.

7. Suppose I'm not satisfied with the first sample?

We immediately activate the technical team for root cause analysis, closely communicate with customers, and provide optimization solutions as soon as possible; remake the sample free until it is fully met by customers' technical requirements. So, we are quite confident to meet customers' standards.

8. How to get started? What information do I need?

You only need to send us 3D drawings, such as STEP, IGES format, with some basic technical requirements. Then our project manager will make an immediate response, professional technical consulting for you, and an accurate quote too after submission.

Summary

Get the most reliable manufacturing support for your designs now! Just click the button below to upload your drawings. Within 4 hours, you will get a detailed quotation including professional DFM advice. Alternatively, you can also directly schedule a 15-minute one-on-one technical consultation with one of our senior engineers.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.