Custom CNC milling services present enormous challenges in the choice of the manufacturers involved. This accuracy can differ from relatively high levels of ±0.05mm accuracy to smaller levels of up to ±0.005mm based on the varying types of milling services involved despite the considerable differences in the levels of costs involved, which are estimated to be around 40% differences. Thus, the above-stated large differences would readily cause inefficient matching levels, thereby further indicating productivity efficiencies of up to 30% lower than the optimal point in addition to the involved risks of the projects.

These issues are connected to the lack of proper framework in the process of selection, understanding of the technology of milling, and cost models based on science - thus causing ineffective decision-making in the decision-making process. The research paper aims to construct an entire framework in making decisions on selection with the objective of choosing an appropriate supplier based on CNC milling services.

Custom CNC Milling Services: Quick-Reference Guide

|

Aspect |

Key Considerations & Options |

|

Milling Process Types |

3-Axis: The most basic form of 3D printing and best suited for less; Multi-Axis (5-Axis/Indexing): Complex shapes, Single setup; High-Speed Milling (HSM) - This is used for finishing purposes. |

| Primary Materials | Plastics: (e.g. ABS, Nylon) - Easy to machine, relatively; Metals: These may include Aluminum, Steel, or Titanium. There are different levels depending on the strength factors & machinability; Other Materials: Composites, Speciality |

| Precision Tolerances | Standard: ±0.1 MM to ±0.05 MM - for most non-critical fits; High Accuracy: ±0.025 mm to ±0.005 mm - For bearings, Aerospace; Above are the four primary cost drivers. Now we will discuss these cost drivers in detail: |

| Key Cost Drivers | Machine Time: Complexity and part size; Material: Type, quantity, waste; Labor & Setup: Programming, fixturing; Finishing: Anodizing, painting, plating. |

| Supplier Evaluation | Inspectable Capabilities:Equipment Match Your Needs; Qualification Certifications: ISO 9001, AS 910; Communication and Prototyping Support. |

The choice of the appropriate supplier with the custom CNC milling service offering will depend on identifying the level of complexity and accuracy required in the product and the technology skills that the supplier has. One of the most essential tasks in this process will be the capacity to identify the most significant variables that will impact the supplier selection with respect to costs and quality.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The current tutorial was prepared in the framework of a citation regarding the experience of the LS Manufacturing because each day we are confronted with a rather complicated task related to custom CNC milling. Our staff has to work in a real workshop but not in a laboratory because working in high-strength alloys means that we are confronted with a rather difficult task. Each recommendation from the tutorial was prepared on the basis of a problem solution. This is the only guarantee for us that the information provided is feasible.

The entire work that we do is based on industry-leading best practices as well as the latest theories. The principles that we follow from the best practices in our solutions are those of the American Production and Inventory Control Society (APICS). In addition to this, other manufacturing processes followed from the MIT Open Course Ware help to keep us well-informed in our respective fields, providing accurate information as a result of leading best practices and the latest theories.

But at the end of the whole process, it is derived from our reputation for fulfilling more than 50,000 orders for CNC machining of custom parts. The reason why CNC machining of critical parts of products like this is performed by us in these industries is that for products like this, accuracy means safety for aviation products, means life for medical products, and means performance for automobiles. The processes that we are sharing with you are actually being implemented by us for these industries.

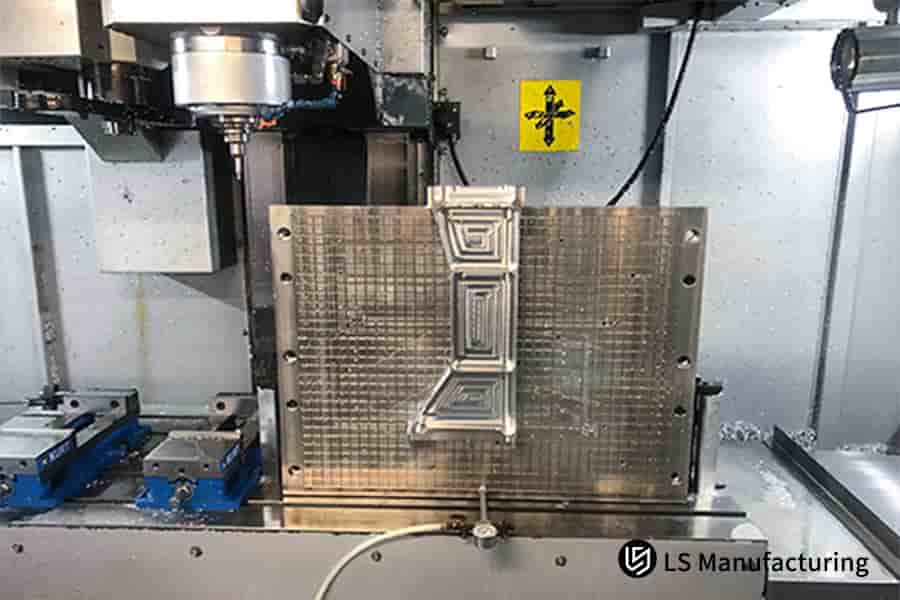

Figure 1: Modern factory's CNC-milled structural parts by LS Manufacturing

How To Choose The Most Suitable CNC Milling Type Based On Part Complexity?

There comes a stage when you are left with the task of trying to maintain the balance that may be required in terms of precision, speed, or cost. It is your responsibility to identify The CNC milling type selection that you may require. It may be 3-axis, 4-axis, or in some cases, 5-axis CNC machining. All this would depend upon your capability or the cost that is associated with it, which would affect you immediately. These guidelines would assist in arriving at your decision, which would be regarding custom CNC milling services.

3-Axis Milling: The Foundation for Simplicity

This milling has been discovered optimal at the area of the prism part for 2.5 D geometries. In the 3-axis milling scenario, economical starting strategy is preferably chosen. It is a point that allows the performance of regular precision CNC milling tolerance values ranging from ±0.1mm to ±0.05mm at astonishingly low costs in the machine, which costs $30k. One of the most fundamental applications of the milling machining process relates to pockets, drilling, or surfaces.

4-Axis Milling: Adding Rotational Efficiency

With the help of the added rotational axis, A-axis, for example, the 4-axis milling operation allows for uninterrupted cutting functions or indexing patterns on a component or piece of work. Efficiencies amplified by at least 50-70% on typical functions like cylinder milling and rim etching make this fall into a very interesting spot between simplicity and complexity, and it also offers a good level of accuracy for contours without necessarily needing a 5-axis machine (~\$80k-150k).

5-Axis Milling: Mastering Complex Geometry

Impellers, molds, and airplane parts with complex, free-form geometries require the machining of the fifth axis simultaneously. This offers unmatched flexibility in terms of accesibility, generally allowing a single-piece process. A relative efficiency improvement of 200% or even higher can be expected for very complex geometries. Zero tolerance precision CNC milling to ±.005mm was performed. The price of such equipment is somewhat high ($200k+). Highly competent personnel are required for the software.

Decision Framework: Matching Type to Task

A scientific selection process starts by analyzing part geometry. Prioritize 5-axis for true 3D contours and undercuts. Use 4-axis for rotational symmetry. Choose 3-axis for all other prismatic designs. Always cross-reference this with batch size, required precision CNC milling tolerance, and total project budget to find the optimal CNC milling type selection for your custom CNC milling services.

In summary, the optimal CNC milling type selection is a direct function of your part's geometric complexity. In an ordered process in your research tasks, in 3 axes for less complicated models and 5 axes in more complicated models, you can be covered in your study in advancing along with technology. In a step by step method in custom CNC milling services, you will be guaranteed final quality in costs and efficiencies in your projects.

What Are The Special Requirements For CNC Milling Technology In Different Industry Applications?

Custom CNC milling services must also change and adapt to some extent in an attempt to meet high standards and demands of high-profile industries. The type of material, accuracy, and quality are an integral part of the holistic approach that directly affects the technical approach of the chosen method. The CNC milling applications have an integral function within the success of this project.

| Industry | Material Focus | Key Requirements | Technical Emphasis |

| Aerospace | Titanium, Inconel, Composites | Ultra-high strength, light, Certification required under AS9100 | Specialized cutting, heat management, and traceability |

| Medical | 316L Stainless Steel, Titanium, PEEK | Biocompatibility, high surface finish, sterility (ISO 13485) | Micro-milling, superior deburring, validated processes |

| Automotive | Alloys, Steel, Plastics | High volume uniformity, economies of scale, durability | Fast cycle time, hardened tooling, SPC control |

Essentially, when selecting a CNC milling manufacturer their experience in the industry would have to be factored in. In fact, the custom CNC milling services offered by the best partner would involve an established procedure that is critical in your industry.

What Are The Key Factors Influencing CNC Milling Costs?

When making a CNC milling quote, you have to be aware of the main factors that are considered to form the entirety of the cost. As a CNC milling cost analysis that seems so at first, this process will surely educate you on the decisions that have to be made and more optimization that is possible through your tailored custom CNC milling services.

| Cost Factor | Typical Share | Primary Drivers | Optimization Strategy |

| Machine & Depreciation | ~30% | Machine capability, age, and cycle time | Optimize CAM for speed; use high-efficiency toolpaths |

| Labor & Programming | ~20-25% | Part complexity, programming time, operator skill | Standardize designs; use experienced programmers. Material Costs |

| Material Costs | ~20% | Type/grade of raw material, stock size, waste | Nest the parts efficiently; consider near-net-shape blanks |

| Tooling & Wear | ~15% | Dependent on tool material, part material abrasiveness, parameters | Apply HSM techniques; use coated tools; monitor for wear |

| Energy & Overhead | ~10% | Facility, quality control, finishing processes | Consolidate orders, lean manufacturing |

The ability to CNC milling cost analysis is, therefore, the answer to helping you control your budget. Now that you know the secret to analyzing the CNC milling quote, I can assure you that your discussion with your supplier will be very fruitful as you can ask for the most effective solutions in your custom CNC milling services.

Figure 2: Large structural component undergoing CNC milling by LS Manufacturing

How To Evaluate The Comprehensive Capability Of A CNC Milling Supplier?

Choosing the right and trusted CNC milling supplier is the crucial area that makes the difference between success and failure in any project. For a supplier to be assessed in making a personal choice, there are four crucial areas that must be considered. These areas will ensure that the CNC milling manufacturer.

Equipment and Technical Capability

There is also a need for an assessment of the equipment that they have. This requires that there be an examination of their equipment capability qualifications so that it may be determined how probable it is that they are capable of multi-axis machining. The availability of high-speed spindles also has a role. The age of the machines also provides a basis for identifying how probable it is that a high degree of precision CNC milling.

Technical Team and Expertise

The best technology that has been developed would be ineffective without an underlying technical team. One needs to consider the overall technical experience, particularly with regards to similar material and similar parts that are involved in your own process. The certifications that you programmers and engineers have, with regards to your industry, will also be taken into account. The overall technical experience in terms of path optimization, problem-solving, and implementing an ideal process at your manufacturing process would be beneficial.

Quality Management Systems

There is a need for a quality management system that is preferably ISO 9001 registered. However, the key is how influential and important the supplier's status as being ISO 9001 registered in their respective industry is, or better yet, As9100 registered in the aviation industry. Moreover, one of the key parts of supplier assessment is the assessment of the process by the supplier in examining carefully the final quality and its documentation. This would ensure that every part of the CNC milling manufacturer is traceable as far as precision CNC milling is concerned.

Service and Communication

The best technical ability is undermined by poor service. Evaluate their responsiveness, project management clarity, and transparency on challenges. Assess their ability to act as a collaborative partner, providing proactive feedback and effective solutions, not just operating as a passive order-taker. This partnership approach is crucial for complex projects.

Thus, for you to be able to do the overall assessment for your CNC milling supplier, you will be required to do the assessment for the machine, people, system, and support environment. This will help you to ensure that you are able to choose the right CNC milling manufacturer so that they are able to do the precision CNC milling for you.

Figure 3: Custom CNC milled aluminum components batch by LS Manufacturing

How Is Micron-Level Accuracy Achieved In High-Precision Milling?

To be able to have a stable level of accuracy at 0.01mm levels, there has to be a total system beyond only basic tools. The level of accuracy in sub-0.01mm precision CNC milling can be gained from the improvement on the current advanced technology. As offer custom CNC milling services, there must be a professional CNC milling manufacturer which excels all aspects capable of providing stable services.

The Basis Support Function

The basis support function for micron-level machining would be to provide a dedicated working site that maintains a controlled ambient temperature, which could range from 20°C ± 1°. The temperature would ensure that there is no expansion with regards to the machines, tools, and components used. There would be no factors affecting the operations of the precision CNC milling because of vibration-reduced floors and smooth airflow within the floors designed to dampen vibrations.

More advanced compensation for machines and errors

It is true with the machine that it too has to be an asset perse. The requirements may include certain specifications belonging to symmetric machines, thermally stiff machines, resolution feedback scales, and also need liquid-cooled spindles. The thermal expansion error correction capability is a fundamental criterion for a sensor for error correction.

Active Process and In-Process Control

A control of any kind is always good in any kind of machining in any form. There should be harmonic tools, appropriate spindle speed in the CNC machine, and specific damping tools which will not chatter and will not resonate. What is particularly special about this process to make this process more precise is on-machine probing. With the use of on-machine probing, the work location as well as the confirmation of the critical dimensioning data can be verified.

Meticulous Tooling and Post-Process Verification

The last criterion needed is related to appropriate tooling and proximity to quality. In regard to this, a search is necessary for quality pre-set tools and issues linked with tool wear and tear. In all matters of verification, what is most important is the fact that every process carried out by the correct CMM would ensure Final Result & thus completes the loop to ensure the deliverance of all services according to micron tolerance in our custom CNC milling services.

In conclusion, reliable micron-level machining is a disciplined approach. It involves a controlled environment, a compensated machine, an actively controlled process, and verification. It is very important to partner with a CNC milling manufacturer that does all of the above with excellence in order to achieve precision CNC milling.

How To Obtain An Accurate And Reliable CNC Milling Quote?

A good quotation system is vital to get a good CNC milling quote. Today, innovative methods use technology for a comprehensive CNC milling cost analysis. This is very beneficial and by understanding how it all works, you will be in a position to compare quotations for your custom CNC milling services.

- Digital Model-Based Analysis: The backbone of modern quoting intelligent analysis forms the basis of your CAD model. An intelligent software system will, therefore, automatically analyze your 3D model while picking out details such as pockets, holes, and curved surfaces among other features. This automated feature recognition provides a precise breakdown of the required operations, setting a factual foundation for the entire CNC milling cost analysis.

- Automated Process Planning: Based on this feature analysis, it automatically schedules the said machining operations. It selects tools to be used, optimal feeds and speeds, and analyzes all operations for the most efficient procedures. This is in line with the best practices in the industry, eliminating human guesswork in developing the initial process plan for the custom CNC milling services that are being quoted.

- Dynamic Cost Processing: This means the solution uses an all-inclusive approach to the integration of all cost drivers that can be quantified in a dynamic, real-time environment. Some of these cost drivers are addressed by dynamic calculation of machine time from the tool paths and current material price databases for raw materials.

- Batch and Requirements Optimization: Lastly, a great system will review orders for quantity and special requirements. It dictates how much money one could save by manufacturing in batches and takes into consideration other processes or rigorous certifications that may be involved. This final stage refines the final CNC milling quote by not leaving any surprise costs after embarking on a particular project.

In summary, an accurate CNC milling quote stems from a systematic, technology-driven evaluation of your part's design. By ensuring the quote is rooted in automated process analysis and comprehensive real-time data, you gain a transparent and reliable CNC milling cost analysis. This allows for confident budgeting and partnership with a provider offering advanced custom CNC milling services.

LS Manufacturing 5-Axis Aerospace Titanium Milling Case Study

For example, a good example can be observed by understanding the way LS Manufacturing is a good solution provider since they have managed to transform difficult challenges within the aerospace industry into manufacturing success. The example aptly shows the way advanced precision CNC milling is necessary for one to be good at custom CNC milling services.

Challenge

An aerospace customer was facing issues in manufacturing 50 Titanium structural parts, entailing heavily complicated machining processes, that would be impossible in 3-axis machining owing to thermal distortion of 0.1mm, thereby permitting no more than 65% yields, thereby going beyond their budget by 40%.

LS Manufacturing Solution

Overcoming such constraints, a solutions-oriented approach was required at LS Manufacturing, and the primary significance was given to 5-axis simultaneous machining capability. The development of customized fixtures that could reduce clamping stresses, optimize cutting parameters to handle generated heat, and work on an in-process measurement concept that would provide real-time error corrections was required. It provided an overall solution of a single setup machining process that could provide unambiguous stability and excellence, a basic requirement of our high-performance precision CNC milling solution for custom CNC milling services.

Results and Value Delivered

The effect was nothing short of dramatic. The accuracy in the final parts remains at ±0.02mm, while the first-pass yield rate touched an incredible 98.5 percent. The project costs dropped by an impressive 30 percent, and the total delivery time was reduced by an incredible 40 percent. This success meant that the client project was delivered on schedule, and in the future, LS Manufacturing was to be the preferred choice for manufacturing.

From this particular case study, it is evident that it shows how technical know-how in 5-axis technology by LS Manufacturing and problem-solving methods can be applied directly from difficult obstacles in high-risk production to high-value outputs. Another aspect this particular case study confirms is the ROI value achieved from working with a firm associated with precision CNC milling.

How Can Small-Batch Production Achieve High-Volume Cost Efficiency?

One of the biggest problems associated with the machining process, as of date, is the challenge of realizing near high volume economies for smaller lots. This report examines strategic methods for the CNC milling manufacturer to help reduce costs per piece considerably, making for unexpectedly economical solutions for custom CNC milling services for smaller lots.

- Advanced Setup and Fixturing Strategies: The first barrier to efficiency is setup time. Implementing modular, reconfigurable fixtures and standardized tooling pallets allows for dramatically faster changeovers. This approach, often part of a lean “SMED” (Single-Minute Exchange of Die) system, directly slashes non-cutting time, a major cost driver in any CNC milling cost analysis for small-batches.

- Intelligent Process and Production Planning: It is the efficiency introduced in the Planning step that is achieved through the utilization of Group Technology to group similar parts together and through the utilization of intelligent CAM software to optimize tool path planning. The best production scheduling software is the software that will be utilized to combine all the above processes in order to create a software that will optimize total machine down time in order to ensure a respondent CNC milling manufacturer.

- Strategic Standardization and Pre-Production: Cost savings prior to the first chip being cut. Develop a library of pre_defined machining processes, approved tools, and designated values for common materials found in many machining tasks to reduce engineering repetitive tasks. This front-loaded preparation standardizes quality and significantly reduces programming and setup time for recurring custom CNC milling services.

- Holistic Cost and Value Optimization: The final section is having a complete comprehension of total cost. Although material and machinetime are considered direct, it is these categories that hold more substantial opportunities for cost reduction, as they relate to indirect labor, inspection time, and scrap. A detailed CNC milling cost analysis that factors in these elements justifies investments in the technologies above, proving that higher upfront process discipline yields the lowest total cost per quality part.

In short, small-batch cost-effectiveness will no longer be an oxymoron but an attainable outcome of successful process innovation. With the optimization of quick changeover times, clever planning, and extensive standardizations, the brilliant CNC milling manufacturer will be able to deliver custom CNC milling services that can provide the versatility of low-volume manufacturing with the economic benefits that can only be harnessed in a massive production environment.

How Do Different Materials Differ In Their CNC Milling Properties?

It is essential to point out that choosing a material for a particular project is critical, and beyond that, machinability is also critical. It is important to state that it is essential to possess a deeper understanding of metal and plastic properties in dealing with a cutter tool in order for one to be successful in CNC milling applications. This will allow one to offer custom CNC milling services for maximum benefits, which will impact precision CNC milling.

Material Removal Rates, Heat, and Response

The first condition that should be considered in material handling is the cutting force required, which translates to heat. Aluminum, for instance, is very tough but easy to handle during cutting. Aluminum has one major issue, however, which is that it tends to accumulate material on the cutting tool. The other metal, titanium, is very strong. This generates high forces during cutting. The material requires low speed, rigidity, and adequate cooling to avoid work hardening during precision CNC milling.

Tool Wear Patterns and Material Selection

Various materials have their unique effects on tool wear. When dealing with stainless steel, a hard material, a notching and tearing action is involved, and a sharpened and coated carbide tool is required. When working with an abrasive composite, polycrystalline diamond tools are needed, as they have greater wear resistance. The primary cause of lack of finish, lack of precision, and higher cost in custom CNC milling services may lie in the misuse of tools on materials.

Surface Integrity and Dimensional Accuracy

The quality of the surface finish and the accuracy of the part being machined are reliant solely on machining conditions unique to particular materials. Engineering materials such as PEEK and Delrin will result in melting and burrs if machined using inappropriate feed rates. The temperature of the machine may present problems in materials with high expansion coefficients at increased temperatures, as in some aluminum alloys. A successful machining operation considers all the above, utilizing unique parameters to create accurate parts in difficult CNC milling applications.

Optimized Parameters for Efficiency

The final aim is making sure that there is a good amalgamation of quality and speed. This is achieved in the CNC machining process by making use of optimized parameters instead of guessed ones. For example, high feed rate and shallow cut are preferred in aluminum, and low feed rate and moderate cut are preferred in tough steel. This is what a good machinist can do.

In conclusion, accurate machining can be defined as a dialogue between the material. One-size-fits-all thinking results in tool breakages, poor outcomes, and high costs. CNC milling applications requires in-depth knowledge of material with respect to forces, temperatures, and tool wear. This domain knowledge can be identified as an indicator that shows an expert who offers excellent quality precision CNC milling in all engineering material

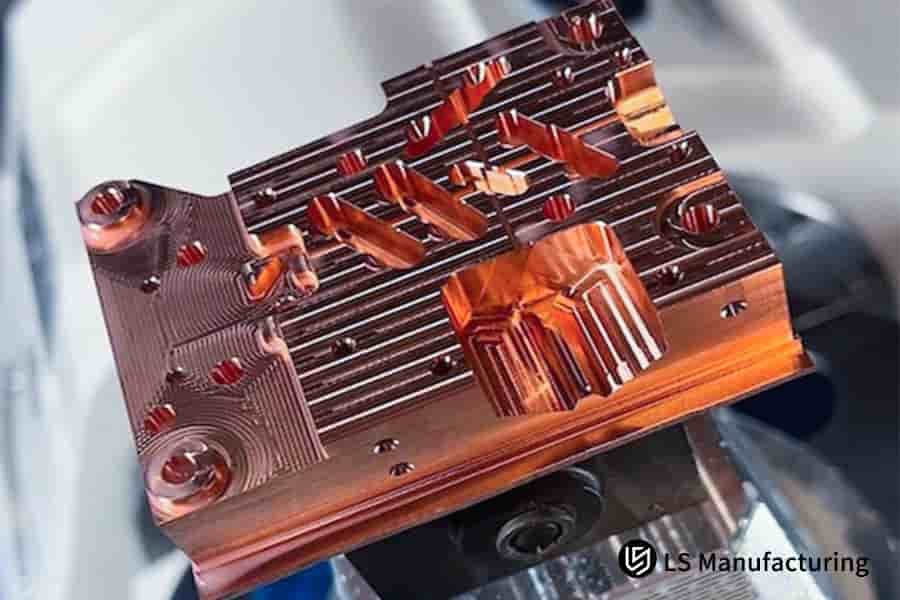

Figure 4: Intricate CNC machined copper alloy part closeup by LS Manufacturing

How To Build A Long-Term CNC Milling Partnership?

While procurement of suppliers represents a transaction, building partnerships represents the keys to unlocking maximum potential for maximum value. CNC milling supplier becomes more than just a processing facility—it becomes an extension of your engineering team because it is crucial for custom CNC milling services.

Foundational Technical and Quality Validation

Every partnership begins with foundational validation of competencies. The initial samples for testing must focus on analyzing the actual potential of the CNC milling manufacturer, from size to quality of the surface. And then, of course, there is the systematic pilot production series to evaluate the quality control and documentation of the producer.

Alignment on Communication and Responsiveness

Trust is built when communication is open and proactive. You must be able to rate their project management, issue escalation, and response times early on in a project. Trust means that a company has visibility into their timelines, that they point out problems before they happen, and that things are done together toward a solution as opposed to issued commands. It’s as vital as skills when considering a long-term relationship between the CNC milling supplier.

Commitment to Joint Improvement and Value

The essence of a strategic alliance is shared efforts for continuous improvement. A quality CNC milling manufacturer will review your production data in order to make recommendations for design for manufacturability, process improvements, or alternatives for cost savings, or so goes the view of analysts in the field.

Systemic Integration and Risk Management

In order to reach the most intense relationships, one needs to reflect on the issue of systemic integrations. This might involve, among other tasks, the management of quality control systems, the sharing of forecasts to foster better capacity management, and the development of common contingency planning. It is through this means that risk management, the resilience of the supply chain, and CNC milling supplier becomes a significant stakeholder in your success.

In other words, a partnership that works is based on proven expertise, communication, and mutual progress. This extends beyond the price of the part, as well as the value of standard custom CNC milling, as it examines how the expertise of the CNC milling manufacturer can add value with regard to quality, speed to market, as well as value beyond what standard custom CNC milling services can normally offer.

FAQs

1. Where exactly does the difference lie between 5-axis and 3-axis machining?

It enables the processing of complex curvature in just one process, decreases clamping, enhances the precision of processing three times, and improves processing efficiency by over 50%. Hence, this could be very useful in the treatment of complex parts regarding Aerospace, Medical Device, etc. This tool possesses efficacy to produce effectively geometric tolerance and surface quality.

2. What is unit cost for an order of small lot size production?

We also take single item orders. Optimized processes and quick changeover systems allow for effective cost management of small orders, providing the possibility of producing unlimited minimum orders. This is ideal for rapid prototype development in line with R&D requirements. Small productions are also applicable in giving our clients the best price offer.

3. What, to your knowledge, is considered normal delivery time for complicated components?

Depending on the level of complexity, it generally needs 5-15 working days. Urgent orders are treated on an expedited basis. By using the expedited process, we could do it within 3-7 days. At the same time, we ensure that we are also on time while delivering our projects to our valuable customers.

4. Are quality inspection reports available for the machining process?

We deliver total satisfaction for quality inspection in terms of quality traceability for both online inspections as well as final inspections. The result for quality inspection includes all quality-related documents such as critical dimension inspection, certificate of material, and process parameter result.

5. Which function does consistency play in mass production?

Through the use of the process for statistical process control, based on the critical dimension of CPK ≥ 1.67, the quality of the mass production of our product ensures the quality stability level of above 99.5% quality. Moreover, our quality control methodology focuses on the three-level inspection process comprising First Article Inspection, Process Inspection, and Final Product Inspection.

6. Do changes to design require a new price quote?

Change involving major alterations demands re-evaluation. Slightly changed requirements can be achieved by making changes to the initial quotation. Change evaluation, which is provided free, helps in change risk associated with cost.

7. Do you offer expedited delivery services for rush orders?

We also have an expediting method of production. We are capable of revising the production schedule depending on the needs of our esteemed customers. We are able to meet their demands for urgent orders. This is because this type of order is normally placed and completed within a period of 72 hours.

8. What technical documents are needed in new projects for forming partnerships?

Please share the 3D models, technology specs, quality factors, and so on. You will receive the full spectrum of technology support services from our technology professionals, along with other services such as process analysis, savings, and timelines to ensure that the flow of your activities is not hampered.

Summary

While considering the selection of the CNC milling service provider, it is important to achieve a balance between technology adoption and efficiency of the service with respect to its cost effectiveness. LS Manufacturing aptly uses technology, experience, and quality management for industry-specific solutions.

For professional milling of components that have been machined using CNC, you could reach out to us to get an adequate solution. We would provide you with an evaluation of our services at no cost to you. We would also get back to you within 2 hours of inquiry to help you through our engineering experts. Click on “Get Customized Solution.”

Achieve optimal quality, efficiency, and value in your CNC milling production. Get your custom quote now.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.