The revolutionary world of 3D printing continues to advance at a rapid pace, and selective laser sintering (SLS) remains at the forefront of these technological strides. SLS technology, an integral part of additive manufacturing, enables the creation of complex structures with exceptional precision and flexibility. This advanced 3D printing method is particularly well-suited for producing parts with intricate details and high-performance features, making it a go-to choice for industries aiming to push the boundaries of innovation. Whether it's for prototyping or end-use part production, SLS brings unparalleled versatility and efficiency to industrial 3D printing.

At the heart of SLS technology is the laser sintering process, where a laser selectively fuses powdered materials layer by layer to form a three-dimensional object. This method not only ensures superior detail and accuracy but also allows for the use of various SLS materials, such as nylon, polyamide, and other specialized polymers. These materials contribute significantly to the durability and functionality of the final products, making them ideal for applications that demand robust and reliable components. From aerospace to consumer electronics, the applications of 3D printing SLS are virtually limitless, enabling industries to realize their most ambitious design concepts.

Spearheading innovative hardware solutions in this landscape is LS Hardware Tech Co., Ltd, a company that embodies the spirit of technological advancement. Established by Mr. Nick Zhang, a seasoned expert with over 20 years of experience, LS has grown into a leading provider of high-precision hardware and plastic parts. The company has effectively served more than 5,000 clients globally, thanks to its state-of-the-art facilities equipped with over 100 high-end machining centers. With a focus on quality and efficiency, LS is ISO 9001:2015 certified, providing products and services to a diverse range of industries including automotive, medical devices, and industrial equipment. Their mission is to continually innovate and offer manufacturing solutions that meet the ever-evolving needs of their customers.

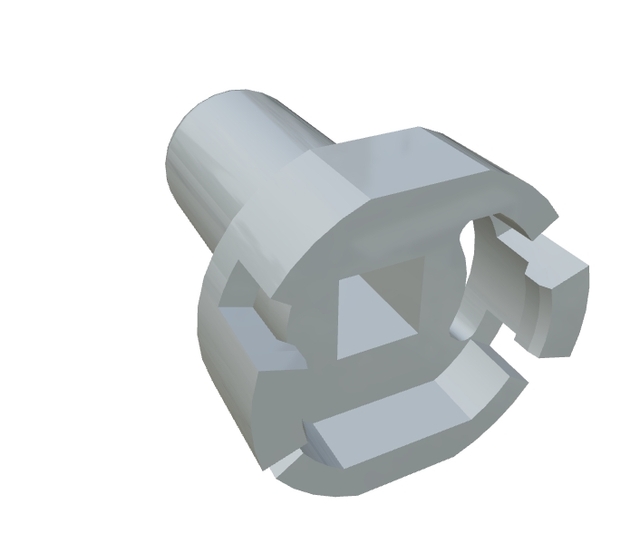

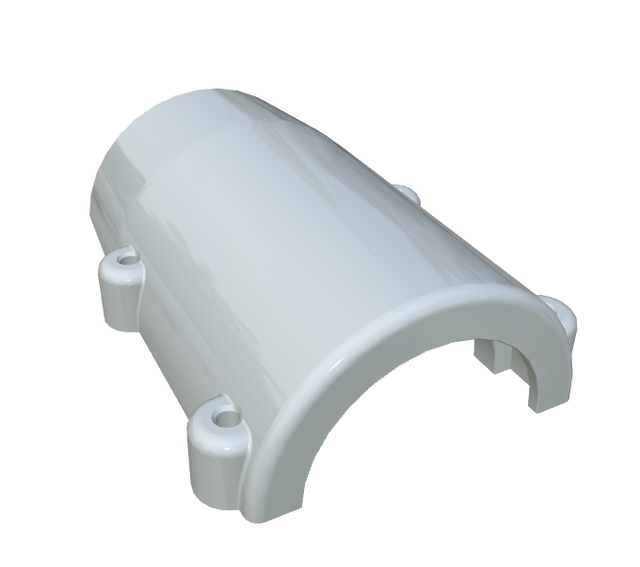

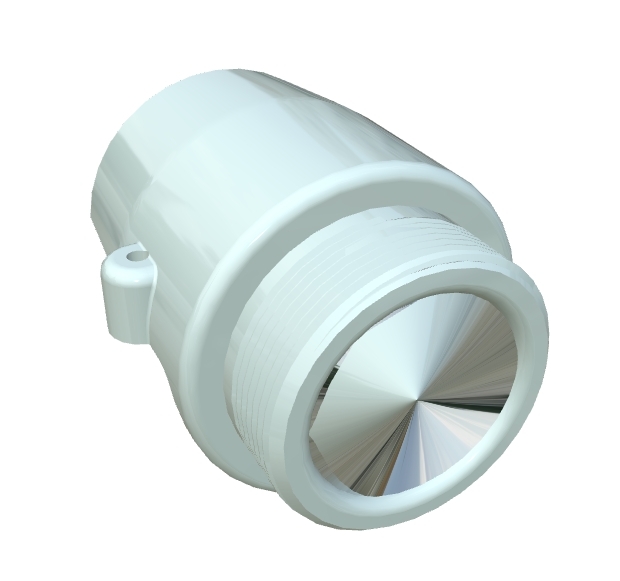

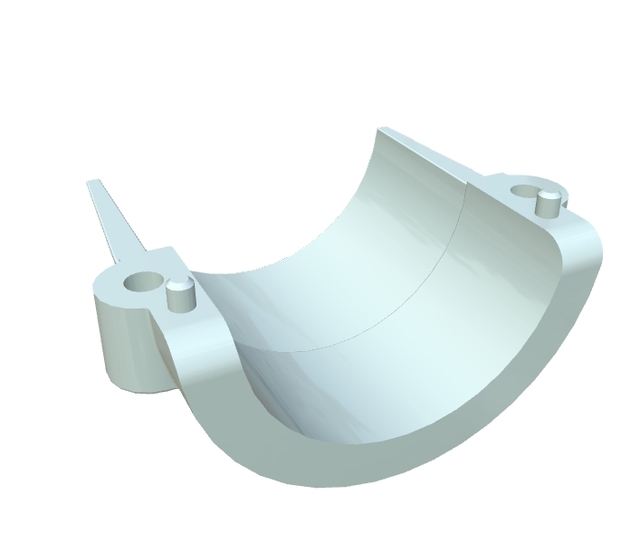

One of the standout products from LS Hardware Tech Co. is the Tri-Lock Fastener, a testament to the company's commitment to quality and innovation. Designed using principles of SLS technology, this fastener features a sophisticated multi-point connection system that promises exceptional stability and precision. Made from high-strength SLS materials, the Tri-Lock Fastener is synonymous with durability and longevity while maintaining a sleek and compact design. Ideal for both industrial and consumer applications, it simplifies the assembly process with its user-friendly installation, saving time and effort without compromising on reliability. The introduction of the Tri-Lock Fastener marks a significant advancement in the domain of secure fastening solutions, setting a new standard for both performance and ease of use.

In essence, LS Hardware Tech Co., Ltd embodies the transformative potential of selective laser sintering in the realm of manufacturing and beyond. With its rich industry experience and dedication to technological excellence, the company not only offers high-quality, precision-made parts but also empowers its clients to unlock new opportunities in design and production. As the possibilities of additive manufacturing SLS continue to expand, LS remains committed to pioneering advancements while supporting its clients with innovative solutions that transcend traditional manufacturing limits. The introduction of products like the Tri-Lock Fastener showcases their ability to harness the power of SLS technology for practical, real-world applications, ultimately paving the way for a future unlimited by the constraints of conventional methods.

By leveraging the unique benefits of the laser sintering process, LS Hardware Tech Co. stands at the forefront of a rapidly evolving industry, reinforcing its status as a trusted partner and innovator in high-precision part production. As the industry continues to evolve, the company's commitment to staying at the cutting edge of technological advancements ensures it is well-equipped to meet future challenges and opportunities. In doing so, LS remains true to its mission: to deliver innovative manufacturing solutions that help clients bring their ideas to life, adapting its processes and capabilities to keep pace with the dynamic needs of the global market.

Exploring Selective Laser Sintering: Revolutionizing 3D Printing and Beyond

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

SLS Technology Advancements: Future, Safety, Applications

Selective Laser Sintering: Revolutionizing Industrial 3D Printing

Exploring the Impact of SLS Technology in Modern Manufacturing

Selective Laser Sintering: Revolutionizing Additive Manufacturing with SLS Technology

Exploring Selective Laser Sintering: Revolutionizing 3D Printing and Beyond

Selective Laser Sintering in Modern Manufacturing

Selective Laser Sintering: Revolutionizing Additive Manufacturing

The Innovations of Selective Laser Sintering Process