Additive manufacturing FDM, also known as fused deposition modeling, represents a revolution in the world of 3D printing. This advanced technology is pivotal in crafting intricate and precise parts across numerous industries. From automotive to medical devices, additive manufacturing FDM is reshaping traditional processes, offering new dimensions of efficiency and innovation.

FDM 3D printing leverages thermoplastic extrusion techniques to build parts layer by layer. This method stands out due to its simplicity and versatility, accommodating a wide range of FDM materials. Different thermoplastics, such as ABS, PLA, and PETG, can be utilized to create diverse components with varied physical properties. This flexibility makes the FDM process suitable for both prototype development and the production of functional parts.

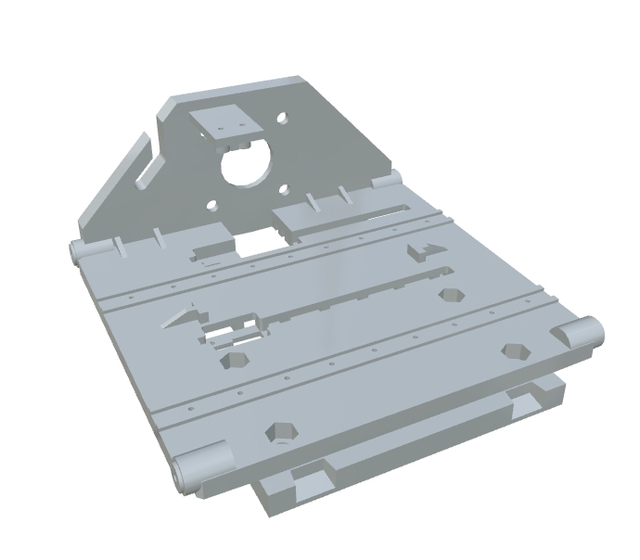

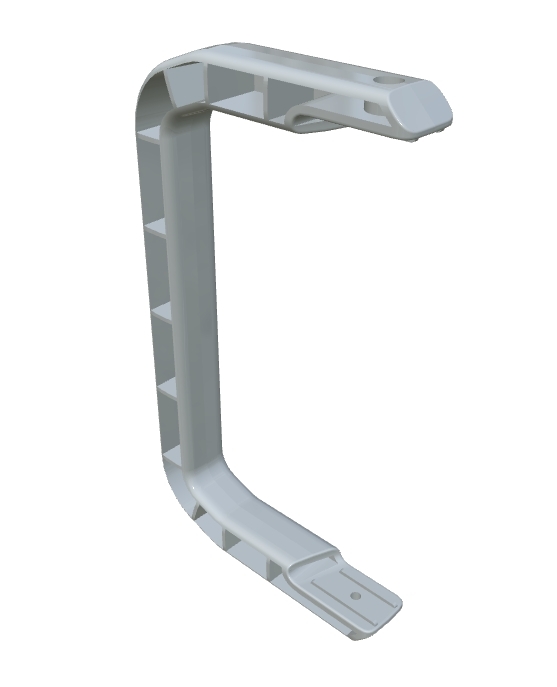

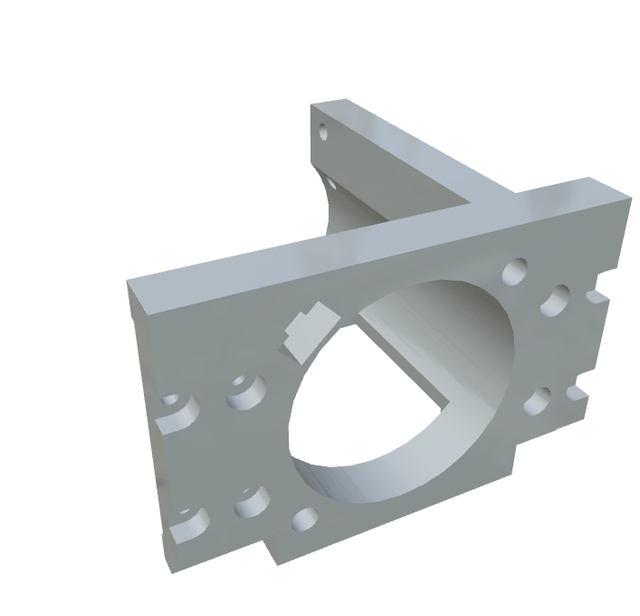

The Sewing Machine Needle Plate from LS Hardware Tech Co., Ltd is a testament to the capabilities of FDM technology. This component is specifically designed to enhance the precision and durability of sewing machines, ensuring a seamless operation for users. Made from high-quality materials, the needle plate boasts superior resistance against corrosion and wear, which is crucial for product longevity. The strategic cutouts and screw holes allow for easy installation, offering consumers a hassle-free upgrade to their sewing machine setup.

Founded by Mr. Nick Zhang, LS Hardware Tech Co., Ltd has been at the forefront of manufacturing excellence for over 20 years. Specializing in hardware and plastic parts, the company has established itself as a leader in the production of high-precision components. With a factory equipped with more than 100 state-of-the-art machining centers, LS ensures high production efficiency and top-quality products. This commitment to quality is reflected in their ISO 9001:2015 certification, which upholds the stringent standards of operation across all company activities.

LS Hardware Tech Co., Ltd serves a vast customer base spanning over 150 countries and regions worldwide. Their expertise extends across various industries, including automotive, medical devices, consumer electronics, aerospace, and industrial equipment, to name a few. The company's mission focuses on delivering innovative manufacturing solutions that empower clients to bring their pioneering ideas to life.

The advantages of FDM technology are evident in its application to the Sewing Machine Needle Plate. The process's precision allows for the creation of components with perfect stitch alignment, minimizing wear and tear on the fabric. This aspect is particularly beneficial for users who demand excellence and reliability from their sewing machines. Additionally, the FDM advantages include cost-effectiveness and reduced material waste, contributing to sustainability in manufacturing.

As industries continue to look for ways to enhance productivity and quality, additive manufacturing FDM remains a leading solution. By embracing this technology, LS Hardware Tech Co., Ltd exemplifies a commitment to innovation and customer satisfaction. Their expertise in crafting high-precision parts positions them as a trusted partner to major factories, both within China and internationally.

In conclusion, the seamless integration of FDM 3D printing technology into products such as the Sewing Machine Needle Plate highlights the potential of additive manufacturing. LS Hardware Tech Co., Ltd stands at the forefront of this technological transition, delivering exceptional products while meeting the evolving needs of their clients. As they continue to push the boundaries of what's possible with FDM technology, LS exemplifies the promise of a future where precision and efficiency walk hand-in-hand.

Exploring Additive Manufacturing FDM: Innovation & Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Exploring Fused Deposition Modeling in Modern Manufacturing

Fused Deposition Modeling: Transforming Additive Manufacturing

Fused Deposition Modeling: Pioneering 3D Printing Advances

Fused Deposition Modeling: Transforming Manufacturing with LS Hardware Tech Co., Ltd

The Future of Connectivity: Fused Deposition Modeling Transforming Streamline Data Relayer

Exploring Additive Manufacturing FDM: Innovation & Applications