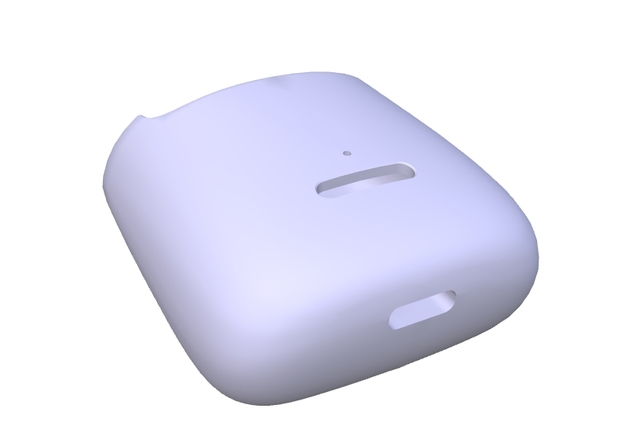

Plastic injection molding is at the forefront of modern manufacturing, providing a seamless blend of precision and practicality. As industries continue to innovate, the injection molding process stands out as an essential method in creating high-quality components like our latest product, the GreenArc Shell. This state-of-the-art method not only ensures cost-effective production but also guarantees the durability and craftsmanship of each piece.

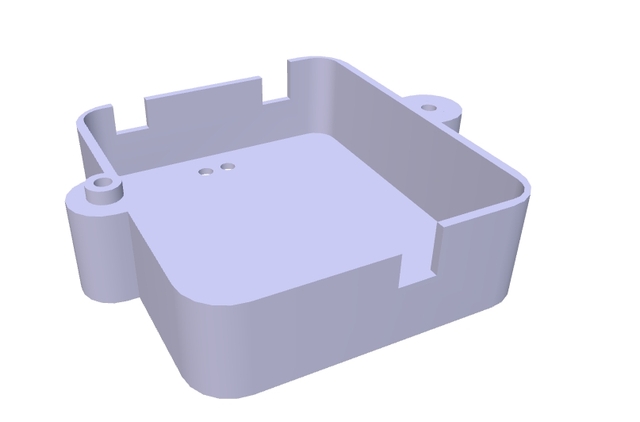

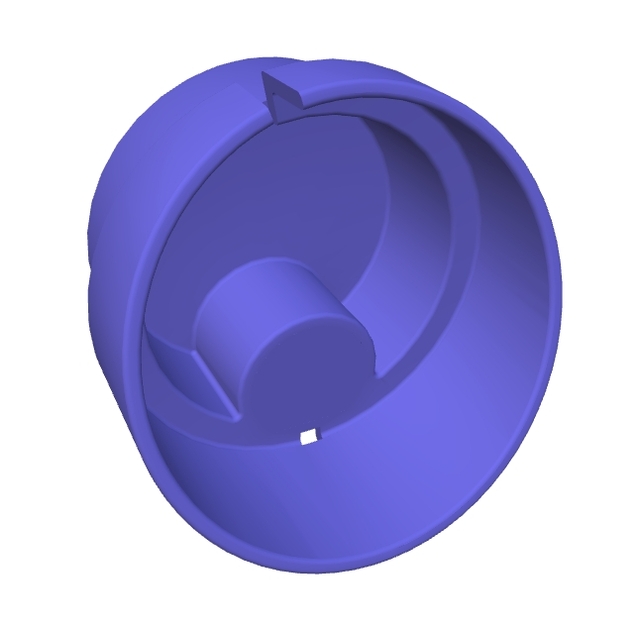

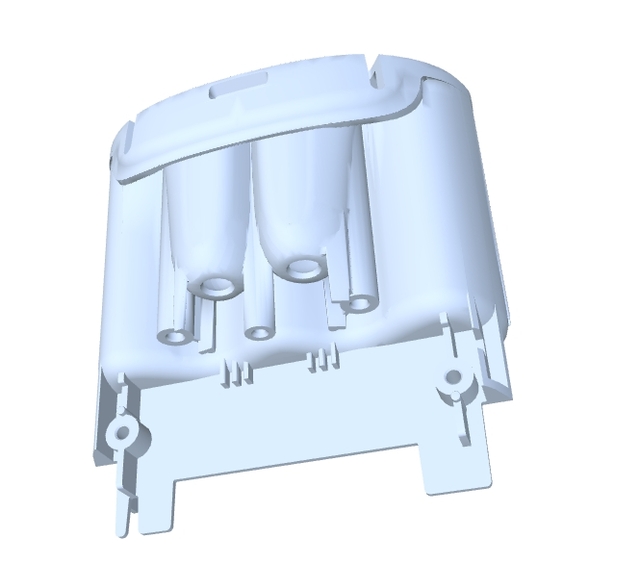

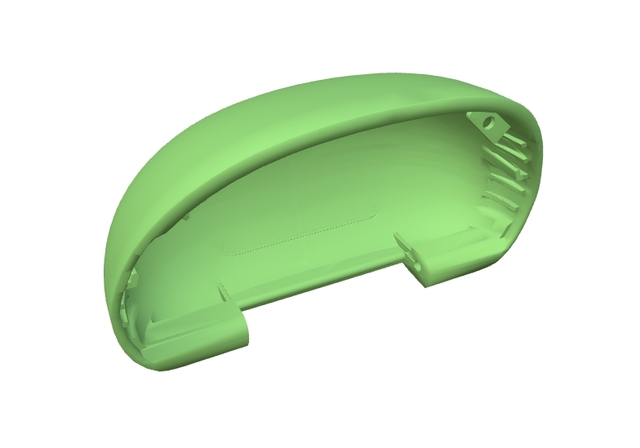

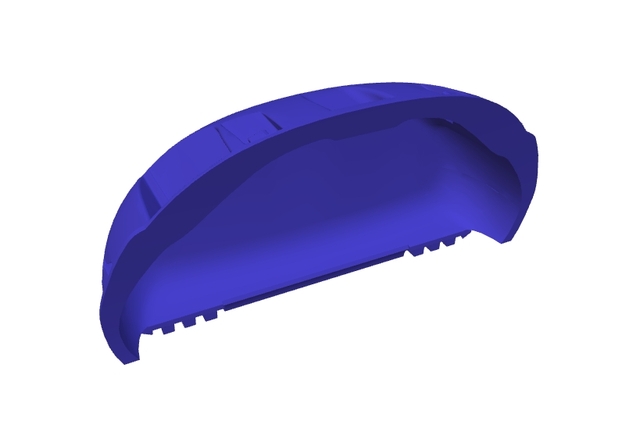

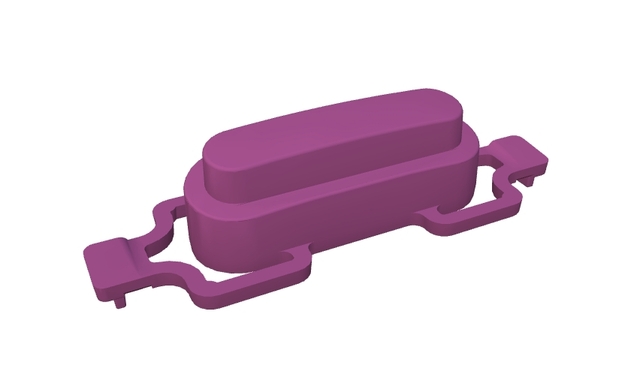

Through custom injection molding and plastic mold making, the GreenArc Shell is designed to meet the highest standards of functionality and style. Each injection molded part is crafted with meticulous attention to detail, ensuring that it enhances the electronic devices it protects. The injection molding process allows for the incorporation of thermoplastic materials, which are renowned for their resilience and performance. This technique plays a vital role in realizing the smooth, aerodynamic shape of the GreenArc Shell, providing users with ergonomic efficiency and a comfortable grip.

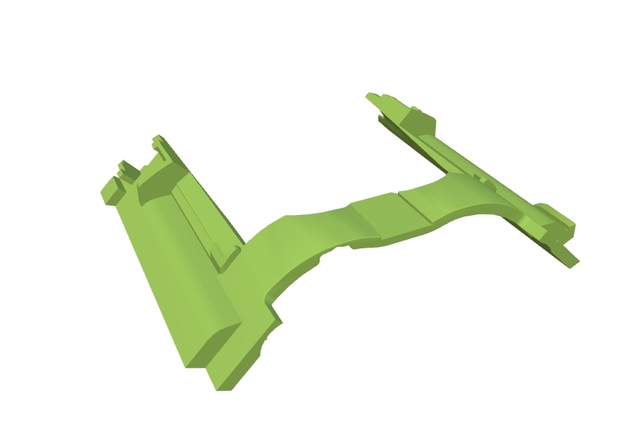

The vibrant and robust GreenArc Shell goes beyond just protective functionality. It is a testament to advanced plastic manufacturing, where creativity and technological prowess converge. Small-batch and large-scale production are made possible through our plastic molding services, ensuring that each shell is consistent in quality and finish. The result is a visually stunning yet practical solution for tech enthusiasts looking to elevate their device's aesthetic and performance. Whether you are upgrading your device's exterior or simply adding a pop of color, the GreenArc Shell offers unparalleled quality for discerning users.

Plastic Injection Molding: The Key to Quality GreenArc Shell

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Overmolding, Insert Molding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Plastic Injection Molding: Innovation in Electronics Cases

Innovations in Plastic Injection Molding: A Deep Dive into Modern Techniques

Exploring Plastic Injection Molding in Modern Manufacturing

Plastic Injection Molding: Revolutionizing Automotive Components

Plastic Injection Molding: The Key to Quality GreenArc Shell

The Future of Plastic Injection Molding: Innovation & Precision

Revolutionizing Production: Plastic Injection Molding Techniques

Understanding Injection Molding Process in Modern Manufacturing