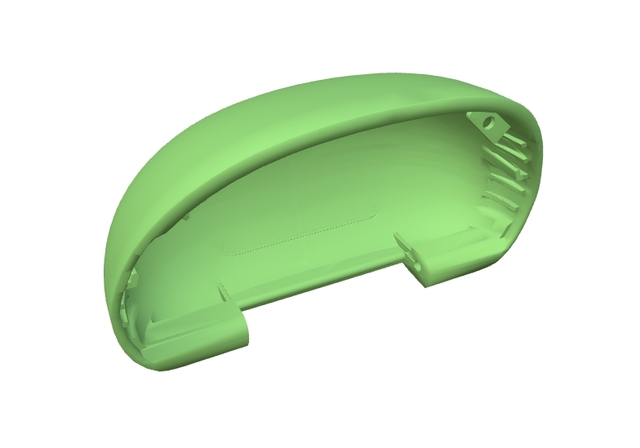

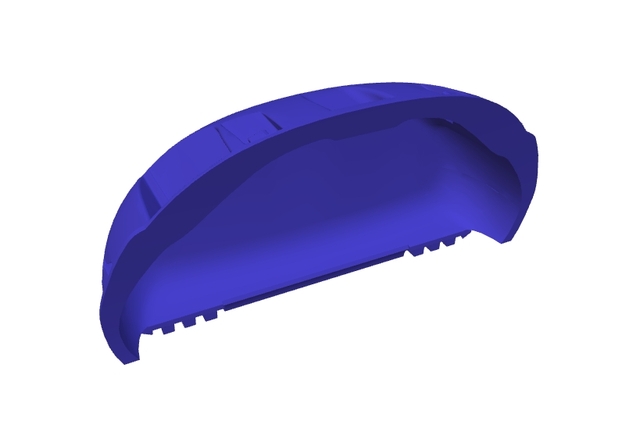

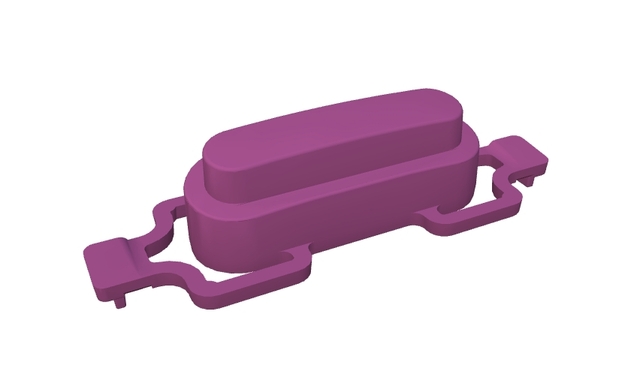

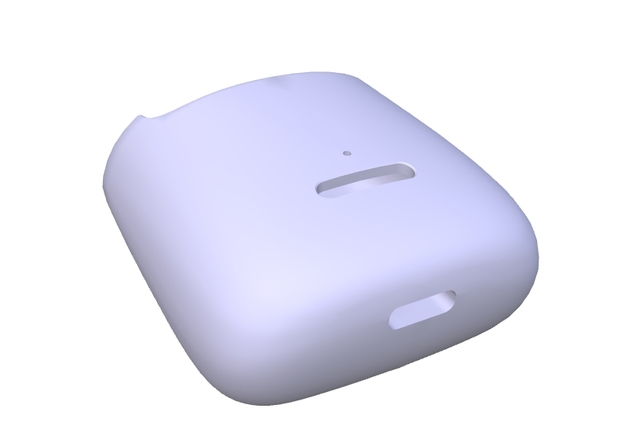

Plastic injection molding has revolutionized the manufacturing sector, particularly in the realm of creating high-precision components such as our new industrial housing unit. This advanced process allows injection molding companies to craft intricate parts with unparalleled accuracy and efficiency, meeting the intricate demands of modern machinery. As a primary technique in plastic mold manufacturing, plastic injection molding ensures that each unit aligns perfectly with its design specifications, enabling smooth integration into complex systems.

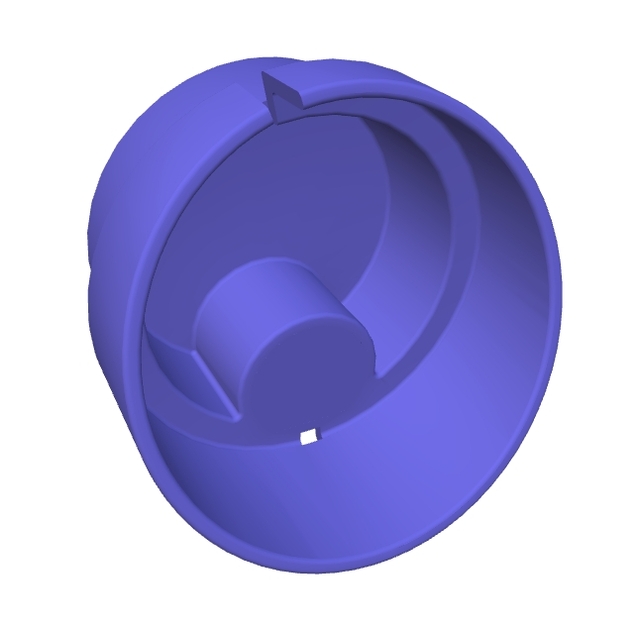

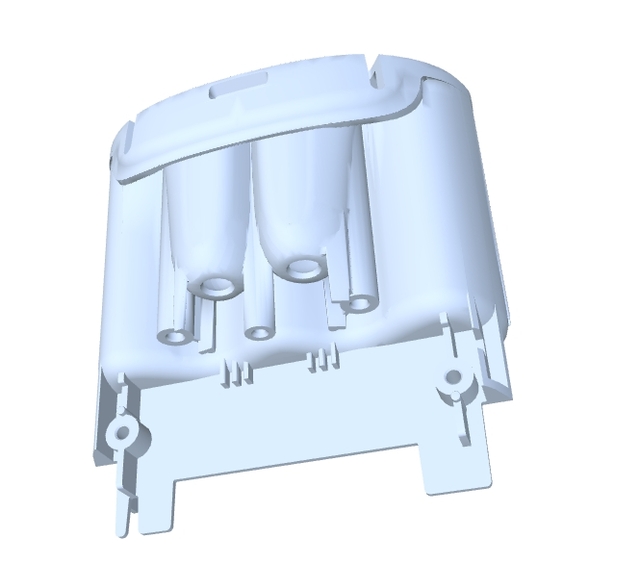

The injection molding process is renowned for its ability to produce durable and high-quality components, making it ideal for manufacturing our state-of-the-art housing unit. This component is crafted to withstand high-stress environments, showcasing robustness and longevity, ensuring it can uphold the integrity of any assembly line or mechanical setup. Featuring an ergonomic design, it includes cylindrical inlets that enhance its versatility, allowing seamless integration with varied conduit systems. This not only broadens its application range across industries but also reinforces its role as crucial support in automated systems.

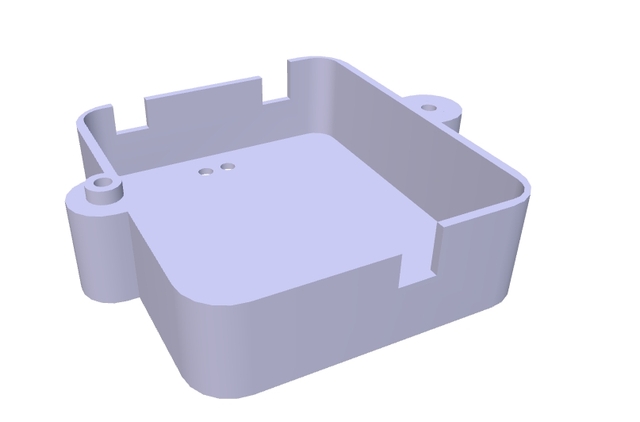

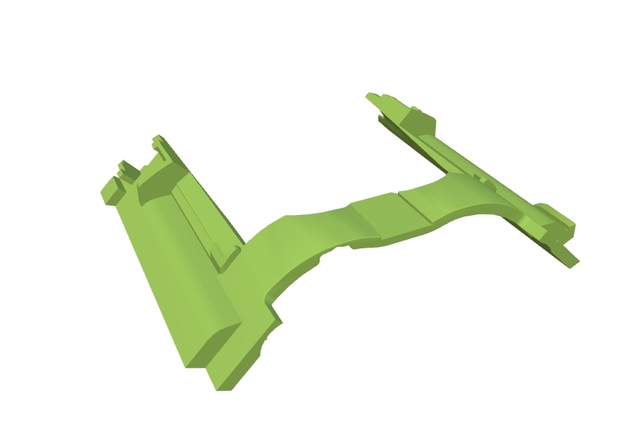

Custom plastic injection molding has further refined the manufacturing process, allowing for tailored designs that address specific industry needs. Through precise plastic molding design, companies can innovate and adapt components that augment performance and safety in automated environments. The strategic placement of mounting holes in our housing unit exemplifies meticulous design considerations, enabling easy installation and secure attachment. This facilitates a secure, streamlined setup that boosts efficiency in industrial operations.

In summary, our new industrial component stands at the forefront of plastic injection molding innovation, combining sleek aesthetics with functional excellence. It is a testament to the capabilities provided by injection molding services and the critical role of custom plastic injection molding in modern manufacturing solutions. The dependability and adaptability of this component make it an indispensable part of advanced industrial systems, reinforcing the efficiency and reliability of today's technological advancements.

Exploring Plastic Injection Molding in Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Plastic Injection Molding: Innovation in Electronics Cases

Innovations in Plastic Injection Molding: A Deep Dive into Modern Techniques

Exploring Plastic Injection Molding in Modern Manufacturing

Plastic Injection Molding: Revolutionizing Automotive Components

Plastic Injection Molding: The Key to Quality GreenArc Shell

The Future of Plastic Injection Molding: Innovation & Precision

Revolutionizing Production: Plastic Injection Molding Techniques

Understanding Injection Molding Process in Modern Manufacturing