In this era of rapid digital advancement,3D printing technologyis reshaping the appearance of manufacturing at an unprecedented speed. Among many 3D printing technologies, stereolithography (also known as SLA) technology is regarded as a leading additive manufacturing method due to its high accuracy, efficiency and ability to create complex shapes. With its unique advantages, this technology has become one of the indispensable key technologies in the future industrial design and manufacturing process.

This article will conduct an in-depth analysis of the working principle, advantages andcommon applications of stereolithographytechnology in multiple fields. The purpose is to show readers how this revolutionary technology leads a new trend in three-dimensional manufacturing.

What is Stereolithography?

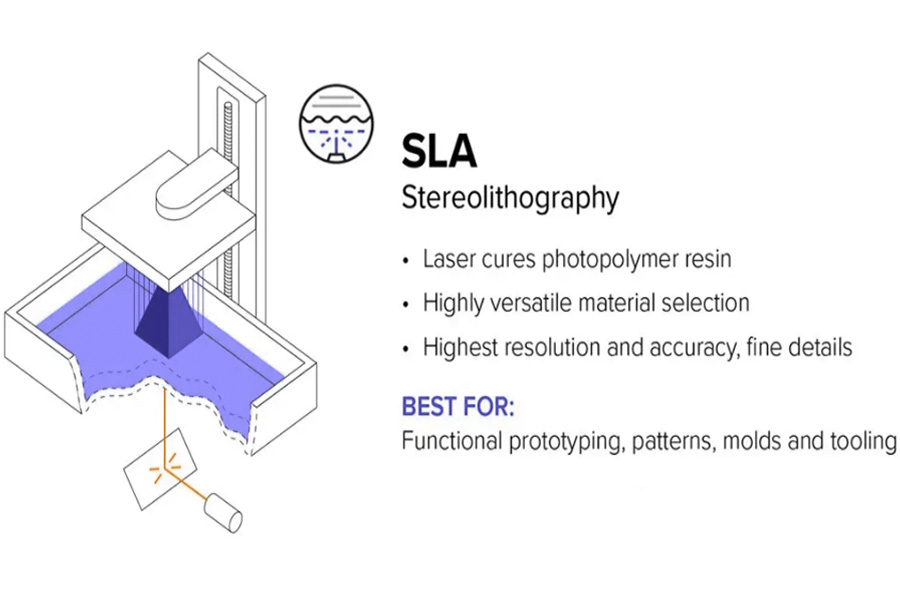

Stereolithography (SLA) represents a 3D printing technologythat uses ultraviolet light to fix liquid resin into a solid substance. This method can quickly prepare three-dimensional structures with high accuracy and resolution. In most cases, the inverted model building platform for SLA printing opportunities is usually placed in a photopolymer resin vat. To make the building process simple and precise, a series of three-dimensional models were invented that could be inverted and run within. The models are constructed from continuous layers thinner than a hair, allowing for high-resolution prints to be produced.

Stereolithography technology uses photopolymers or resins as materials. These photoreactive liquids contain a variety of different ingredients, and the appropriate mixture formula is selected according to its intended application requirements. Complex structures are obtained by depositing layers of different thicknesses and compositions on a substrate. Special properties of the material can be enhanced by mixing various additives such as glass, silicone or ceramic, thereby increasing its ability to be thermally deformed or waterproof. Since no harmful impurities are introduced during the manufacturing process, high optical quality and a high-gloss surface are achieved. This manufacturing process is an ideal choice for those who require high precision and fine parts. Because it can produce high-quality products without processing on the mold, and can obtain various complex shapes by adjusting different proportions. As a result,SLA is widely used in prototyping across multiple industries, ranging from medical devices and instrumentation to aerospace and automotive component manufacturing.

How Does Stereolithography Work?

Theworkflow of stereolithography technologyincludes steps such as preparation stage, layer-by-layer curing, platform lowering and resin supply, repeated curing process, and post-processing.

- First, fill the liquid photosensitive resin into the resin tank of the3D printerand make sure the stage is below the liquid level.

- Then, the computer controls the laser beam to scan the resin surface point by point according to the preset 3D model slicing data to solidify the resin in the exposed area.

- After one layer of curing is completed, the stage is lowered by a preset layer thickness, and the liquid resin in the resin tank is automatically replenished above the cured layer to prepare for the next layer of curing. This process is repeated until the entire3D modelis constructed layer by layer.

- Finally, necessary cleaning and post-curing treatments are performed to obtain a complete 3D printed product.

When was stereolithography invented?

- Early 1970s:Japanese researcher Dr. Hideo Kodamainvented modern layered stereolithography, which uses ultraviolet light to cure photopolymers.

- 1984:American inventor Charles Hull patents stereolithography, a technology subsequently used to create 3D models.

- 1986:Charles left the UV Products Company and founded his own company, 3D Systems, and began to focus on the development of 3D printing technology. Based on stereolithography technology, the company became the first company in the world to produce 3D printing equipment.

- 1988:3D Systems launched the SLA-250, the world's first 3D printer based on stereolithography technology. This technology began to attract attention from the industry and was gradually applied in various fields.

What Are the Advantages of Stereolithography?

Theadvantages of stereolithography technology (SLA)mainly include:

-

High dimensional accuracy.SLA can produce parts with very high dimensional accuracy and intricate details.

-

Smooth surface finish.SLA parts have a very smooth surface finish, making them ideal for visual prototypes.

-

Material choice.Specialty SLA materials are available, such as clear, flexible and castable resins.

-

Speed.SLA printing is the fastest form of 3D printing, making the technology well-suited to rapid prototyping and small-batch production.

-

Minimal warping or shrinkage.Unlike other 3D printing methods, SLA-printed parts usually typically exhibit minimal warping or shrinkage while printing, resulting in high degrees of dimensional accuracy.

-

Minimal waste.SLA printers use liquid resin efficiently – and leftover resin can often be reused – resulting in minimal material waste.

-

High resolution.SLA technology maintains high resolution consistently across the entire build volume, enabling uniform quality throughout large prints.

What Are the Disadvantages of Stereolithography?

Thedisadvantages of stereolithography (SLA)mainly include the following points:

- Material brittleness:The photosensitive resin used in SLA can be more brittle than some thermoplastics, which limits its use in applications requiring high strength and toughness.

- Post-processing requirements:After SLA printing is completed, post-processing steps such as curing and cleaning are usually required, which increases the overall processing time and cost.

- Higher cost:The equipment purchase cost, material cost and maintenance cost of SLA technology are usually higher than other 3D printing technologies (such as FDM).

- Relatively slow printing speed:Because SLA builds objects by solidifying liquid resin layer by layer, its printing speed is relatively slow and is not suitable for rapid prototyping or mass production.

- Sensitive to the operating environment:The SLA printing process needs to be carried out under specific environmental conditions, such as controlling air humidity and temperature, which increases the complexity of the operation and its dependence on the environment.

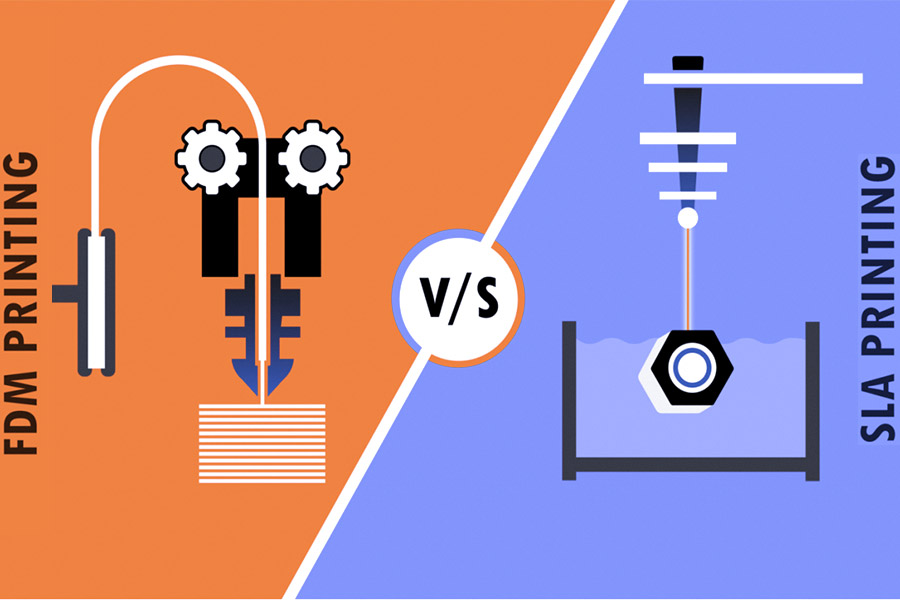

What Is the Difference Between Stereolithography and FDM?

Stereolithography (SLA) and FDM (Fused Deposition Modeling) are two common 3D printing technologies, and there are significant differences between them. Here is a table outlining the main differences between SLA and FDM:

| Stereolithography (SLA) | FDM (Fused Deposition Modeling) | |

| How it works | Liquid photosensitive resin cures rapidly under ultraviolet laser illumination | By heating and extruding the plastic filaments, layer by layer is stacked to form the final model |

| Precision and detail | High precision, able to capture fine details, and the surface of the printed object is smooth | The accuracy is relatively low, and the surface of the printed object has obvious lamellar lines |

| Speed and efficiency | The print speed is relatively fast, especially when printing over a large area | The printing speed is relatively slow and requires the material to be stacked layer by layer |

| Cost vs. materials | Equipment and photosensitive resin materials are more expensive | The price of equipment and plastic filament materials is relatively low |

| Post-processing and maintenance | Post-processing steps such as curing, cleaning, and sanding are required, but the effort is relatively small | Post-processing steps such as removing support structures and sanding surfaces can be relatively heavy |

| Scope of application | Medical, jewelry, hand molds, and other industries that require high precision machining, as well as prototyping and product development that require high precision and detail | Prototyping in education, architecture, advertising, industrial design, and other fields, as well as scenarios that require a large number of prints and do not require high accuracy |

What Are the Applications of Stereolithography?

Stereolithography technology (SLA) has the characteristics of high precision, high surface quality, material diversity, etc., so it is widely used in many fields, as follows:

1. Prototype development and design verification

SLA technology can quickly convert CAD digital models into three-dimensional physical prototypes, helping designers and engineers conduct intuitive design evaluation and optimization in the early stages of product development. This technology is particularly suitable for product prototyping with complex shapes and structures, which can greatly shorten the product development cycle and reduce development costs.

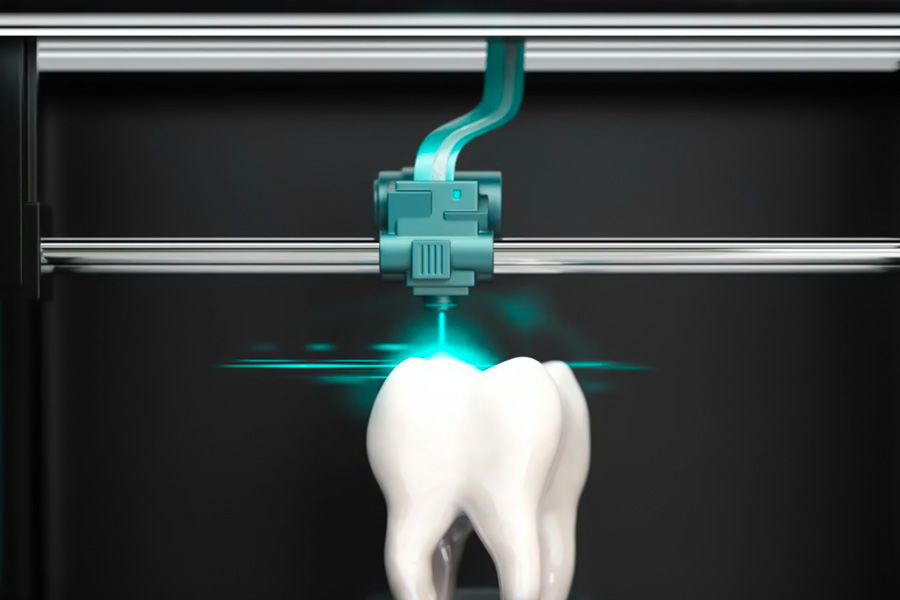

2. Medical field

In the medical industry,SLA technology is widely used to produce personalized medical devicesand implants. For example, dental models, surgical guides, prosthetics and orthotics, etc. can be customized. These customized products can better adapt to the individual needs of patients and improve the accuracy and success rate of surgery.

3. Automobile manufacturing

The application ofSLA technology in the field of automobile manufacturingis mainly reflected in prototype development, functional testing and production of molds. It can quickly produce high-precision prototypes of automotive parts for design verification and functional testing. In addition, SLA technology can also be used to produce tooling fixtures and rapid molds to meet customized needs and small batch production in automobile manufacturing.

4. Aerospace

In the aerospace field,SLA technology is used to manufacture complex structural parts, engine parts, and spacecraft shells. These parts often need to work in extreme environments, so materials are required to have high strength, high toughness and high corrosion resistance. SLA technology is able to meet these requirements and produce products with complex geometries and details.

3D printing provider LS can provide a variety of 3D printing services, including SLA, PolyJet and SLS technologies.

SLA (stereolithography):

- LS provides high-precisionSLA printing services, suitable for models that require front-facing surfaces and intricate details.

- LS will help you choose the appropriate photosensitive resin material and provide post-processing services such as cleaning, curing, and coloring.

PolyJet expertise:

- LS’s PolyJet servicecan print multi-material and multi-color fashion, perfect for prototypes and visible fashion.

- They offer a wide range of fabric options and ensure that the printed models have smooth surfaces and precise details.

SLS (Selective Laser Sintering):

- LS’s SLS printing serviceis suitable for the production of functional parts, especially those requiring robustness and power.

- LS will help you select the best thermoplastic powder material and provide necessary post-processing such as grinding and dyeing.

LS can provide professional advice and high-quality 3D printing services based on your specific needs. Whether you need prototypes, functional parts, or creative pieces, they've got you covered!

Summary

Stereolithography (SLA), also known as stereolithography technology or light-curing technology, is an advanced 3D printing technology that uses liquid photosensitive resin as raw material and solidifies the resin layer by layer through ultraviolet laser under computer control to create a three-dimensional solid model. Since its inception, this technology has been widely used in many fields due to its high precision, high surface quality and diverse material selection. With the continuous advancement and innovation of technology, I believe that SLA technology will play a more important role in the future and bring more convenience and surprises to our lives.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.What is stereolithography?

Stereolithography (SLA for short) is an advanced 3D printing technology that builds three-dimensional entities by solidifying liquid photosensitive resin layer by layer. This technology is based on the principle of photopolymerization, using ultraviolet laser beams to accurately scan the surface of the liquid resin, causing the resin in the exposed area to quickly solidify, thereby superimposing layer by layer to form the final 3D model.

2.How does stereolithography work?

The workflow of stereolithography technology includes steps such as preparation stage, layer-by-layer curing, platform lowering and resin supply, repeated curing process, and post-processing. First, fill the liquid photosensitive resin into the resin tank of the 3D printer and make sure the stage is below the liquid level. Then, the computer controls the laser beam to scan the resin surface point by point according to the preset 3D model slicing data to solidify the resin in the exposed area. After one layer of curing is completed, the stage is lowered by a preset layer thickness, and the liquid resin in the resin tank is automatically replenished above the cured layer to prepare for the next layer of curing. This process is repeated until the entire 3D model is constructed layer by layer. Finally, necessary cleaning and post-curing treatments are performed to obtain a complete 3D printed product.

3.What are the advantages of stereolithography?

Stereolithography technology has the advantages of high precision, high detail expression and wide material selection. It can print complex three-dimensional structures with fine surface quality, making it ideal for producing detailed models, prototypes and artworks. In addition, with the continuous development of technology, stereolithography technology can also use a variety of different photosensitive resin materials to meet different application needs.

4.How is stereolithography different from other 3D printing technologies?

Compared with other 3D printing technologies, the biggest difference between stereolithography technology is the materials and printing methods it uses. Stereolithography technology uses liquid photosensitive resin as a printing material and solidifies it layer by layer to build a three-dimensional entity. Other 3D printing technologies such as fused deposition modeling (FDM) use filamentous materials such as plastic or metal powder to build up layer by layer. In addition, stereolithography technology also has higher precision and detailed expression, and can print more complex and fine structures.

Resource

Aplication of the stereolithography technique in complex spine surgery