The **sand casting process** is a foundational method in the manufacturing industry, particularly valued for its versatility and cost-effectiveness. This technique involves creating metal components by casting molten metal into sand molds. Over the years, the process has become widely adopted in diverse industries, including automotive, due to the multitude of benefits it offers over other manufacturing techniques.

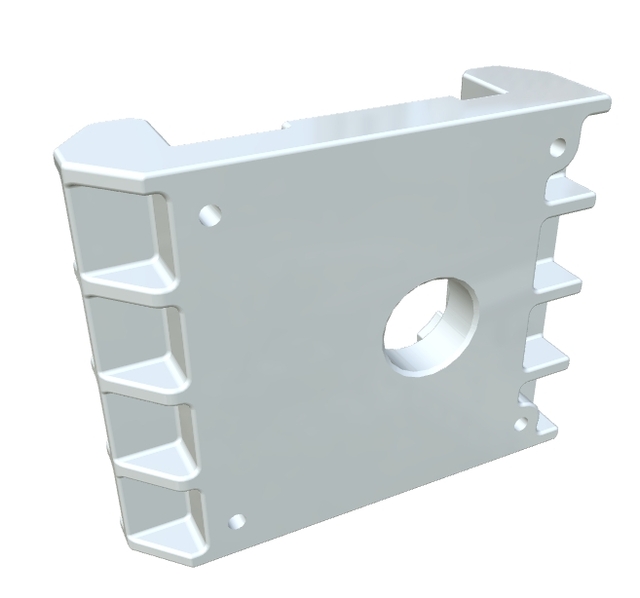

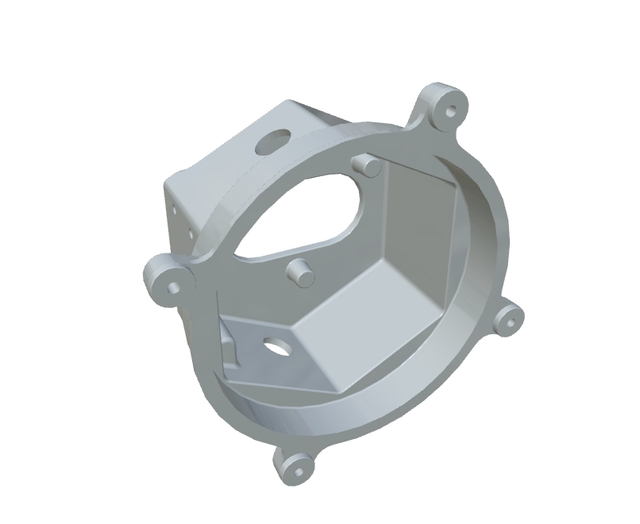

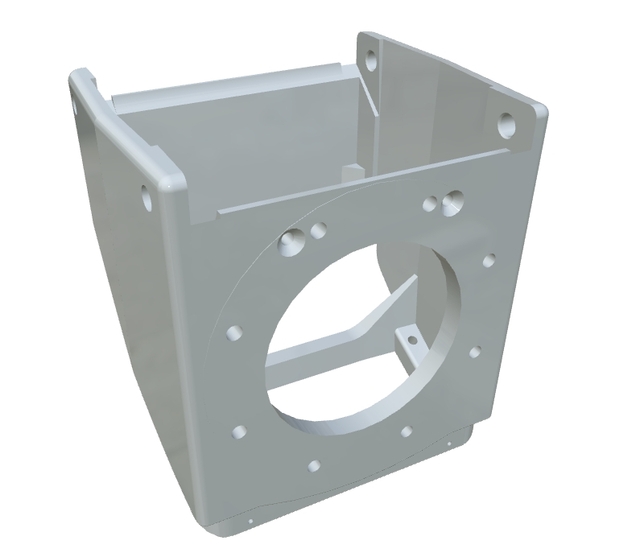

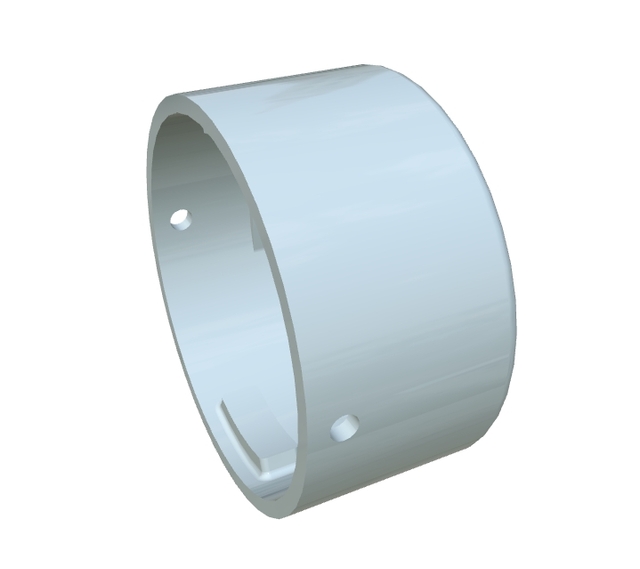

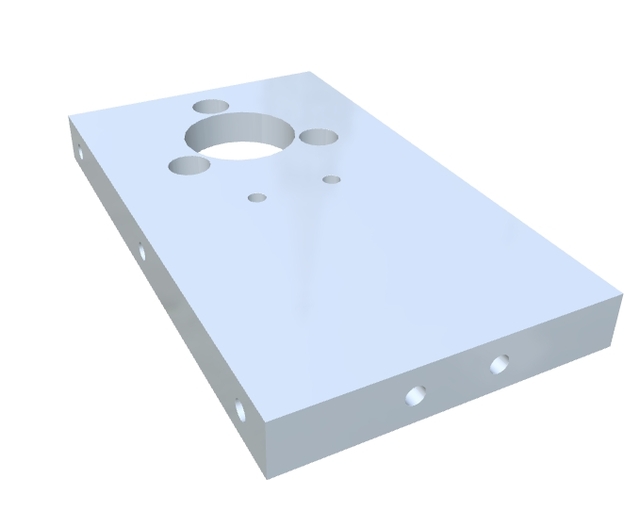

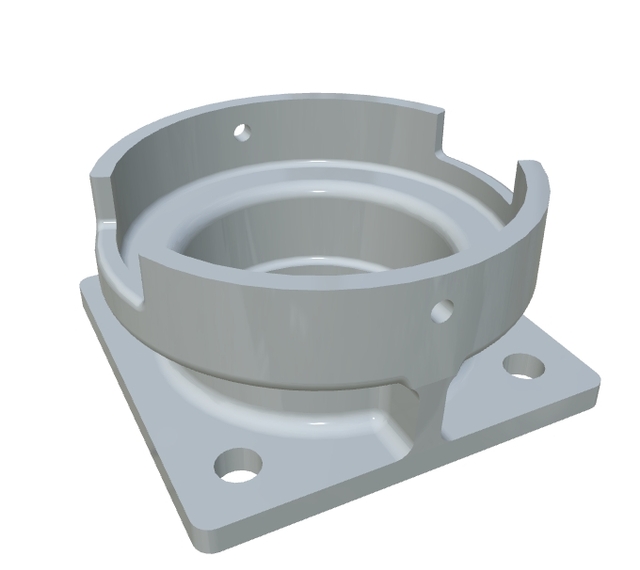

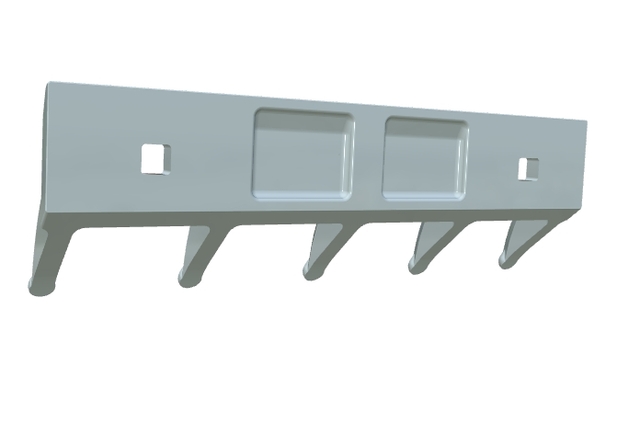

One of the primary **benefits of sand casting** is its ability to handle complex shapes and sizes that other casting methods may find challenging. This makes it particularly suitable for producing parts like the automotive transmission system, where precision engineering and efficiency are paramount. The materials used in sand casting are predominantly silica sand, clay, and water, which are molded around a pattern of the desired shape, creating a negative impression to house the molten metal. The sand casting materials are key to ensuring the quality of the final product, providing the necessary durability and stability.

However, like any other industrial process, sand casting is not without its challenges. **Sand casting defects**, such as shrinkage, porosity, and surface imperfections, can occur, but with advanced techniques and vigilant quality control, such issues can be minimized. Understanding **how sand casting works** allows manufacturers to optimize the process, ensuring that components such as the cutting-edge automotive transmission system are crafted with precision. This precision is crucial in automotive applications, where the seamless integration of parts can significantly impact performance and fuel efficiency.

When comparing **sand casting vs metal casting**, the former stands out for its economical nature, especially in producing small-batch items or prototypes. Additionally, the sand casting techniques have evolved substantially, allowing for enhanced accuracy and surface finish, making it a viable alternative for parts previously restricted to metal casting methods. This adaptability is a testament to the sand casting process's enduring relevance in industries focused on innovation and efficiency. Types of sand casting include green sand casting, dry sand casting, and shell mold casting, each offering unique benefits depending on the specific requirements of the product.

In conclusion, the sand casting process continues to play a significant role in the production of vital components such as automotive transmission systems. This process not only supports the demand for high-quality, durable parts but also aligns with the industry's pursuit of balancing power and economy through advanced technology. As manufacturers strive for excellence, the incorporation of modern **sand casting techniques** enhances their ability to deliver sophisticated and functional products, embodying the future of automotive technology.

Techniques de moulage au sable : méthodes modernes pour des conceptions complexes

Obtenez le dernier prix >

| Label | Value |

|---|---|

| Marque | Fabricants de pièces personnalisées LS |

| Service de personnalisation | Moulage métallique, Coulée de sable, Coulée à basse pression, Coulée à haute pression, Casting d'investissement |

| Format du dessin | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Capacités des matériaux | Aluminium、Laiton、Bronze、Cuivre、Métaux durcis、Métaux précieux、Acier inoxydable、Alliages、TPR |

| Échantillon | Libre |

| Capacité d’approvisionnement | 100000 pièces par jour |

| Finition de surface | Finition sur mesure |

| Épaisseur | Épaisseur personnalisée |

| Type | Brochage/Perçage/Gravure / Usinage chimique/Usinage laser/Fraisage/Tournage/EDM à fil/Prototypage rapide/Autres services d’usinage |

| Services | Usinage CNC,Moulage de métaux,Moulage par injection,Fabrication de tôles,Prototypage rapide,Impression 3D |

Trouver des produits similaires

Contact

Prêt à commencer votre prochain projet avec LS Manufacturing?

Contactez-nous dès aujourd'hui pour en savoir plus sur nos services et comment nous pouvons vous aider à atteindre vos objectifs.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdDes délais de plomb rapides à partir de seulement 1 jour ouvrable.

ISO 9001, ISO 14001, IATF 16949 et certification AS9100D.

Plus de 100 matériaux disponibles, avec plus de 50 options de finition de surface.

Production de masse rentable.

Commander aussi bas que 1 pièce.

Les gens qui ont vu cela ont également vu

Procédé de moulage au sable : avantages et techniques

Techniques de moulage au sable : méthodes modernes pour des conceptions complexes

Casting Agency: Essential Services for Entertainment

Services de moulage experts pour des composants de précision

Le processus de moulage au sable : techniques, matériaux et applications

Le procédé de moulage au sable : avantages et techniques dévoilés

Maîtriser les techniques de moulage au sable pour des solutions innovantes

Explorer le processus polyvalent de moulage au sable dans la fabrication moderne