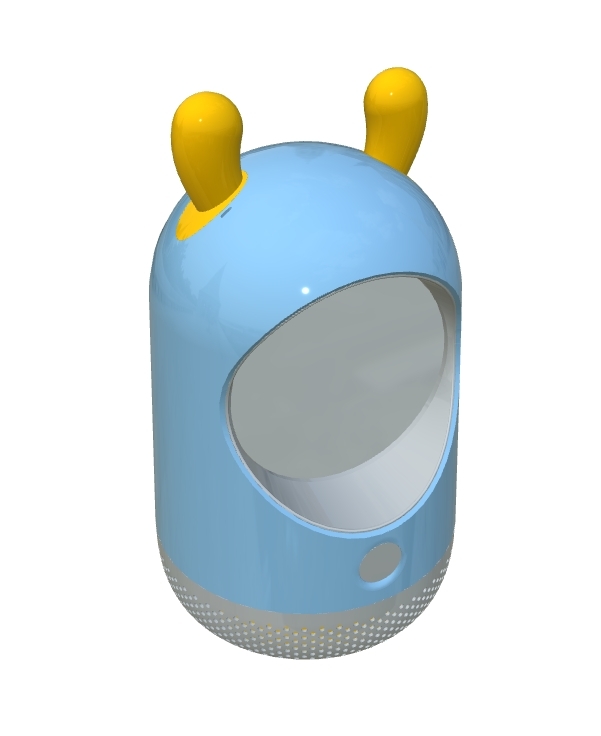

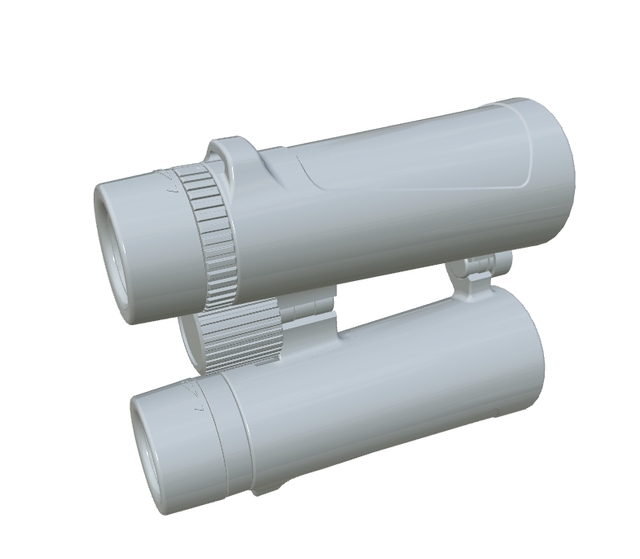

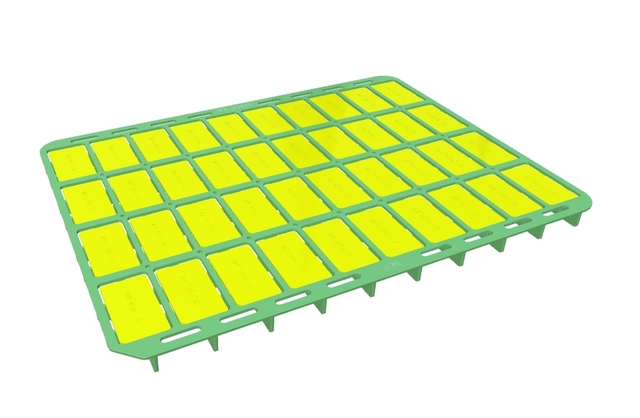

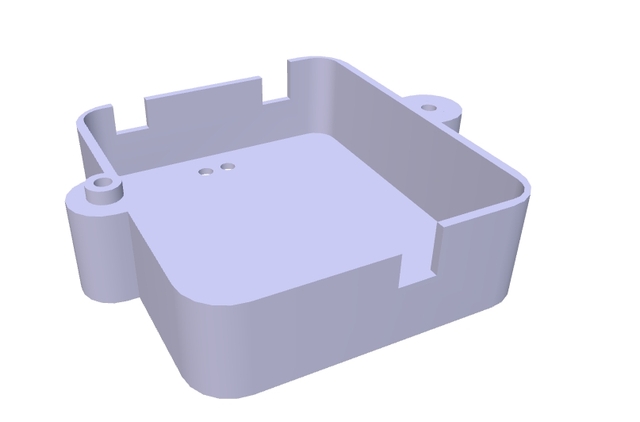

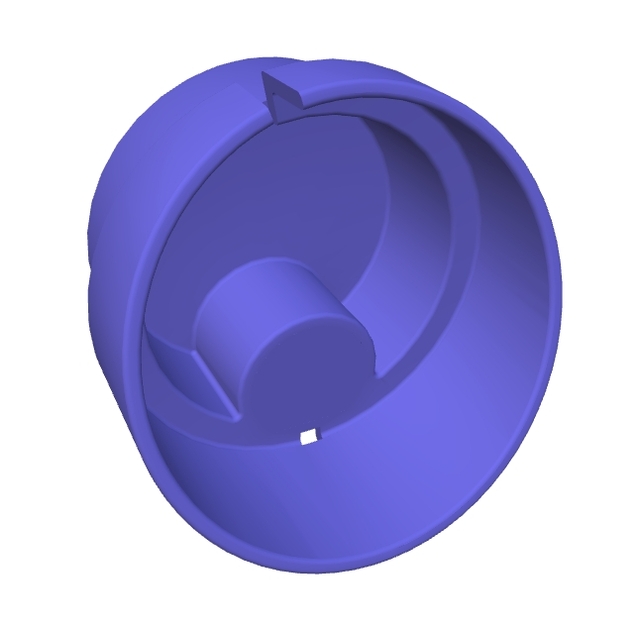

Insert molding has emerged as a revolutionary process in the manufacturing industry, especially concerning precision components like the Precision Grip Dial. This state-of-the-art insert molding process enables the seamless integration of plastic and metal parts, offering a composite design that features unmatched ergonomic benefits and durability. Insert molding techniques ensure the best possible performance for components that require manual adjustments, ensuring that these products meet modern needs with precision and efficiency.

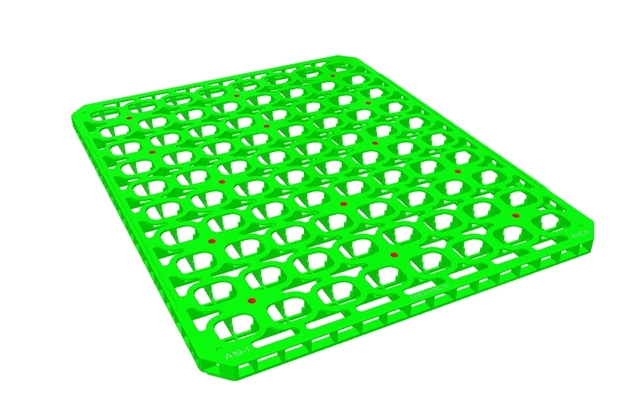

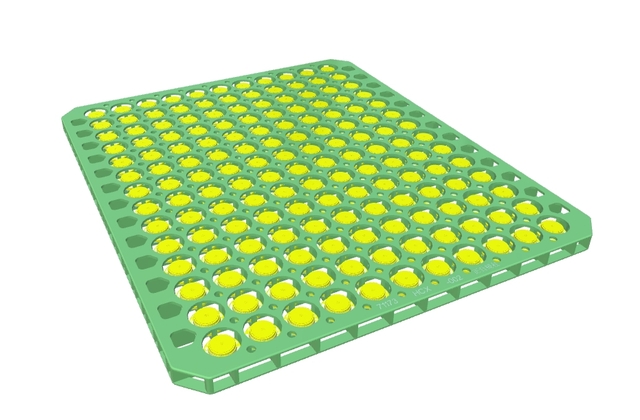

The insert molding process involves placing an insert, typically made of metal, into a mold before injecting plastic around it. This method allows for the creation of a strong bond between materials, facilitating reliability in even the most torque-intensive applications. With insert molding manufacturing, companies can produce bespoke designs such as the Precision Grip Dial with unparalleled consistency and quality. Given its lightweight and durable composition, the Precision Grip Dial showcases the sheer potential of insert molding applications, particularly in extending the longevity and functionality of small but integral components.

Choosing the right materials plays a pivotal role in insert molding. Combining the right insert molding materials with skilled craftsmanship ensures that products maintain high performance even under stress. Custom insert molding caters to unique designs and specifications, providing tailor-made solutions that reflect innovation and intent. Whether addressing insert molding design requirements or focusing on improving user experience with ergonomic features, custom insert molding offers endless possibilities. As the spike in demand for advanced manual adjustment tools continues, companies harnessing insert molding have a competitive edge in delivering new-age solutions to various industries. From improving design aesthetics to enhancing functional capabilities, insert molding remains a critical component in crafting intuitive, reliable, and stylish products like the Precision Grip Dial.

Revolutionizing Products with Insert Molding Techniques

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Overmolding, Insert Molding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.