In the world of metalwork and component production, **progressive die stamping** has emerged as a pivotal technology that elevates the manufacturing process. As industries continue to demand efficient, precise, and cost-effective solutions, progressive stamping technology meets these criteria and provides unparalleled advantages. LS Hardware Tech Co., Ltd, a highly esteemed company, leverages this technology to produce exceptional products such as the Wall-Mount Bracket. This innovative product exemplifies the potential of metal stamping and reflects the company's commitment to quality and customer satisfaction.

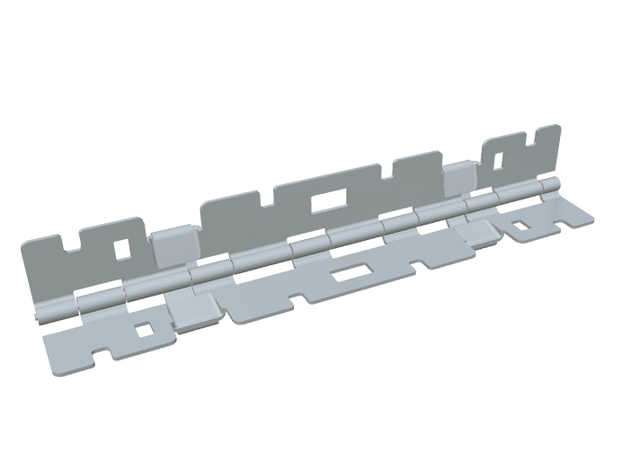

Progressive die stamping, one of the most advanced methodologies in metal stamping, involves a sequential process where a strip or coil of metal is introduced into a series of stations within the die. Each station performs a distinct operation, which could include cutting, bending, or piercing, culminating in the creation of a complex part. This method is highly efficient as it can be operated in a continuous loop, producing parts at high speeds without compromising on quality. LS Hardware Tech Co., Ltd capitalizes on this technology to ensure the accuracy and reliability of its products, including custom die stamping for diverse applications.

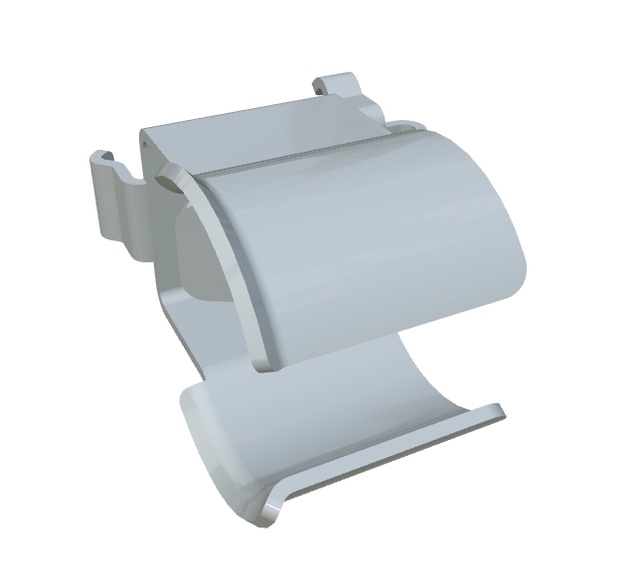

The intricate design of the Wall-Mount Bracket showcases the precision and creativity needed in die design for stamping. Each detail, from the integrated cable management slots to the contoured curves, is meticulously crafted to fulfil both aesthetic and functional demands. The metal stamping process ensures that each bracket is uniform in quality, essential for maintaining the structural integrity required to securely hold devices or tools in an organized manner. This makes the bracket an ideal choice for office use, workshops, or homes aiming for a clutter-free environment.

LS Hardware Tech Co., Ltd, with its strong foundation and expertise, has made significant contributions to automotive stamping parts and precision stamping, providing high-quality components to automotive and other major industries. Founded by Mr. Nick Zhang, an expert in manufacturing hardware and plastic parts, LS prides itself on delivering innovative solutions to over 5,000 clients globally. The company operates over 100 advanced machining centers, ensuring high production efficiency and exceptional product quality. This capability allows LS to produce stamped metal components with precision unmatched by competitors.

The company's prowess is not limited to hardware, as it also excels in producing high-precision parts for various sectors such as medical devices, consumer electronics, aerospace, and industrial equipment. The ISO 9001:2015 certified company is dedicated to utilizing cutting-edge technology and continuously improving its processes. This commitment enables LS to deliver innovative manufacturing solutions that empower clients, forming a trusted partnership with major factories in China and beyond, reaching over 150 countries and regions worldwide.

A significant aspect of progressive stamping technology and its application in products like the Wall-Mount Bracket is the sustainability factor. By optimizing the use of materials and minimizing waste in the production process, LS Hardware Tech Co., Ltd contributes to environmentally responsible manufacturing practices. As industries and consumers alike become increasingly conscious of environmental impact, the role of precision-engineered components becomes ever more crucial.

In conclusion, the Wall-Mount Bracket exemplifies the innovative spirit of LS Hardware Tech Co., Ltd and the transformative power of progressive die stamping. This metal stamping technique not only enhances production efficiency but also guarantees high-quality, durable, and aesthetically pleasing products. As LS continues to explore and develop within the industry, their dedication to quality and precision remains a benchmark for excellence. For businesses and individuals seeking advanced solutions in organizational infrastructure or hardware applications, LS Hardware Tech Co., Ltd stands ready to provide products that meet and exceed expectations.

Progressive Die Stamping: Elevating Metal Component Production

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Progressive Die Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Progressive Die Stamping: Revolutionizing Metal Fabrication

Progressive Die Stamping: Innovative Metalwork Techniques

Revolutionizing Manufacturing with Progressive Die Stamping

Mastering Progressive Die Stamping: A Key to Precision

Progressive Die Stamping: Elevating Metal Component Production

Progressive Die Stamping: Precision & Innovation

Progressive Die Stamping: Efficiency in Metal Stamping Solutions

Progressive Die Stamping: Precision Meets Innovation