Metal blanking, as an efficient and precise forming process, occupies an important position in modern industrial manufacturing. It is through blanking tool to metal sheets impact or pressure, according to predetermined shape and size of the separation, so as to achieve accurate and efficient processing effect.

As a leading metalworking service service provider the industry, LS Company has a high level of technical expertise, advanced equipment and extensive experience in handling complex metal punching tasks. This paper aims to explore the precision control technology of metal blanking, analyze various factors that affect blanking accuracy, and introduce the advantages of LS in blanking process.

What is metal blanking?

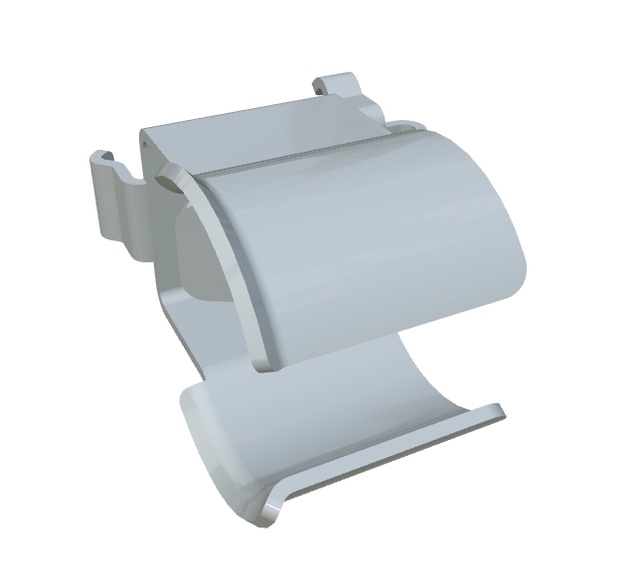

Metal blanking is a manufacturing process that takes advantage of the the plastic deformation characteristics metal materials to process raw materials into precision parts of specific shapes and sizes and to exert high-speed pressure on metal sheets through molds and punching tools. Its core processes include blanking (separation process) and forming (bending, stretching, etc.) and are widely used in automotive bodies, aerospace components, precision electronics, etc.

In the process of metal blanking, the design and manufacture of punching tools play an important role in the quality of stamped parts. Therefore, it is the key factor to ensure the precision and quality of metal blanking parts to design the tool reasonably, choose the appropriate process parameters and control the process strictly. As a professional metalworking service provider, LS Company has a wealth of hardware blanking experience and advanced technology equipment to provide customers with high-quality hardware blanking services and solutions.

What are the types of materials used in the blanking process?

1. Common metal materials

- Low-carbon steel (e.g. SPC, Q235B): high plasticity, easy processing, low cost, suitable for general punching processes

- Stainless steel (e.g. SUS301, SUS304): has a strong corrosion resistance, but has a noticeable tendency to harden work, suitable for special circumstances of the punch.

- Aluminum alloys (e.g. 6061, 6063): Aluminum alloys are relatively light in mass, low in density, good electrical and thermal conductivity, but have remarkable elasticity and are suitable for blanking parts that require weight reduction.

2.Special metal

- High strength steel (such as DP steel, TRIP steel): tensile strength ≥ 150 MPa, but prone to cracking when blanking.

- Titanium alloys (e.g. TA15, TC4): High specific strength, corrosion resistance, but sensitive to processing temperature.

- Magnesium alloy (e.g. AZ31B, WE43): Lightest metal structural material, flammable, requiring strict temperature control control.

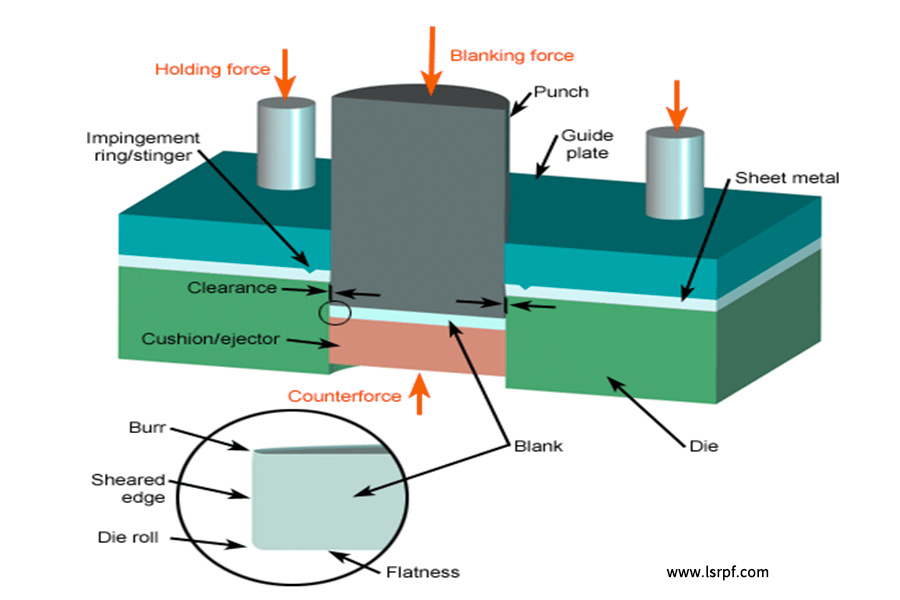

How does metal blanking work?

1.Material pretreatment

- Material choices: SPC carbon steel), SUS301 (stainless steel), 6061 aluminum, etc., with thickness tolerance + -0.05mm.

- Surface treatment: phosphating/galvanizing (increase mold life), lubricating coating (reduce friction).

- Flattening and cleaning: Elimination of plate bending (≤ 0.03mm/m) and surface impurities.

2.Mold system

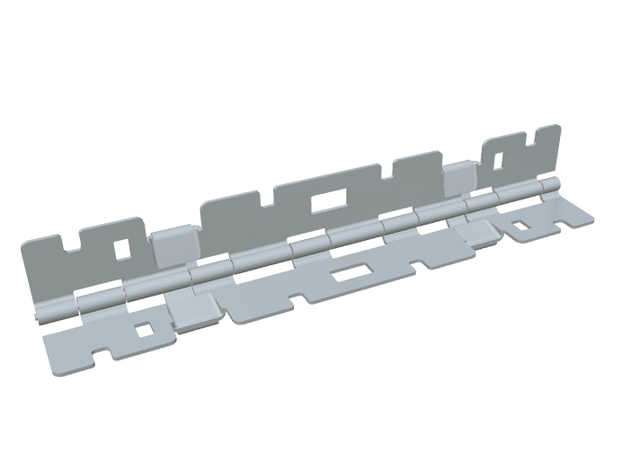

| Mould type | Structural characteristics | Typical applications |

| Single process mold | Convex mold+concave mold+discharge plate | Small batch simple parts |

| Composite mold | Nested convex concave mold+rigid discharge | Medium batch high-precision parts |

| Continuous mode (progressive mode) | Multi station arrangement+material guide pin positioning | Large quantities of complex parts |

- Positioning stage: The feeder delivers the sheet to the specified position of the die (accuracy ± 0.01mm), assisted by vacuum adsorption or guide pin positioning.

- Pressure application: Hydraulic/mechanical press at high speeds (0.1-200m/s) can produce thousands of tons of thrust.

- Material deformation:

Shear separation: The convex mold penetrates the material, while the concave mold die carries waste (typically shear plane tilts 45 °).

Plastic forming: The production of slip lines during bending/stretching (such as yield plateau for low carbon steel).

- Unload phase: The spring/pneumatic device ejects the punching part and the waste is discharged automatically.

4.Comparison of typical process types

| Process type | Processing method | Speed range | Applicable material thickness |

| Cold blanking | Shear at room temperature | 0.1-10m/s | 0.1-6mm |

| Heat blanking | Heating the material to above 600 ℃ | 0.05-2m/s | 2-8mm |

| Hydroforming | High pressure liquid drive | 0.01-0.5m/s | 0.5-4mm |

5. Follow up processing

The cutting parts are depilated, cleaned and leveled to improve the cutting precision and appearance quality. Further machining parts as required, such as cutting, drilling, welding, etc.

What are the influencing factors of metal blanking process?

Material properties (directly affecting processing feasibility)

1. Material strength

- High-strength steel (such as DP steel): punching speed must be reduced or a mild flush used, otherwise cracking is easy.

- Aluminum alloy: remarkable elasticity recovery, require negative clearance blanking (clearance 5% -8% less than material thickness).

2. Material thickness

- Ultra-thin plate (<0.1mm): Hydraulic pad assist or liquid nitrogen cooling is required to prevent deformation.

- Thick plates (>4mm): a large tonnage press are required and corner collapse defects occur easily.

- Oil/oxide layer: Causes poor lubrication or mold adhesion.

- Phosphating/galvanizing layer: Improved mold life, but required matching lubrication conditions.

Mold design and manufacture (determine upper limit of accuracy)

1. Leaf geometry

- Circle radius: Too small (Ra<0.05 μ m) leads to wear and tear, while too large (Ra>0.1mm) leads to burrs.

2. Gap control

- Ordinary blanking: gap=Material thickness × (0.05-0.1)

- Precision blanking: Negative clearance (e.g. -0.03mm for aluminum alloy) reduces recoil.

3. Mold hardness

- TD Coated Mould (HRC85-90): 300% increase in service life, suitable for high precision requirements.

- Ordinary Carbide (HRC60-65): Low cost but easy to break.

Process parameters (directly affecting yield)

1. Punch Speed

- High-speed punches (>100m/s): High efficiency but easy to vibrate and requires active damping system.

- Low speed blanking (<10m/s): suitable for high strength steel or thin-walled parts.

2. Tons of presses

- Calculation principle: Tonnage ≥ material shear strength x punching area equals safety factor (usually 1.2-2).

- Typical value: blanking 2mm SPCC board (σ b=345MPa) requires tonnage ≥ 200 tons.

3. Lubrication conditions

- Dry friction: Low cost but easy mold wear (SPC).

- Oil based lubrication: reduce friction coefficient to 0.05, prolong the service life of the die.

Common defects and countermeasures

| Defect type | Cause analysis | Solution |

| Burr | Blade passivation and excessive gap | Re grind the blade edge and use negative clearance |

| Flanging/twisting | Insufficient unloading force and elastic recovery | Install pneumatic unloading and optimize clearance |

| Crack | Material stress concentration and excessive punching speed | Warm blanking, reducing punching speed |

What are the application fields of metal blanking?

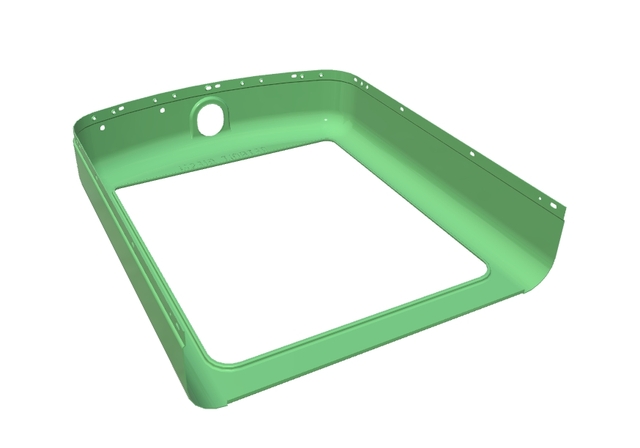

1.Automobile manufacturing: metal blanking is especially important in automobile manufacturing. A large number of metal presses are used for body components such as doors, soot engines, hood, trunk lid, chassis attachments, engine attachments, gearbox attachments, etc. These stamped parts not only meet the structural and functional requirements of automobiles, but also improve production efficiency and reduce costs.

2.Aerospace: The manufacture of key components such as aircraft hood, exterior and interior building panels usually requires sophisticated metal blanking processes. These components not only require high strength and rigidity, but also need to meet the requirements of lightweight.

3.Healthcare: From medical devices to medical device components, metal blanking parts are widely used for their precision and reliability. Titanium implants, for example, are common in medical implants.

4.Electronic products: from the cooling hole of computer chassis to the internal structure of portable devices such as mobile phones, metal punch not only provides necessary structural support, but also meets the aesthetic and functional requirements of the products.

How to choose blanking tools?

According to the characteristics of the punch.

1. Material and specifications:

- For medium and small metal punch, bending or shallow stretch, open punch presses or open mechanical punch should usually be selected.

- For large, medium and high precision blanking products, it is recommended to use a door press or a double axle press or a closed mechanical press.

- If the material needs high strength and rigidity processing, such as leveling, bending correction, molding and other special technology, we should choose a punch or punch with corresponding properties.

2. Finished Size and Precision:

Considering the size and precision requirements of stamped parts, choose a punch tool that can meet these requirements. For example, a high-precision punch may require the selection punching machines high-rigidity or high-capacity punch.

Choose according to production needs.

1. Production batch

- For mass production (more than100000 units peryear), high-speed presses or multiple fully automated presses can greatly improve production efficiency and molding quality.

- Flexible blanking tools such as manual presses or small mechanical presses are available for small-scale or trial production (500-5,000 units/month).

2. Process requirements:

- Select appropriate blanking tools such as blanking, bending and deep drawing according to the nature of blanking process.

- Taking into account the special requirements of processing, hydraulic presses are selected if larger force stroke is required.

Choose based on production costs

| Scheme | Applicable scenarios | Initial Investment | Maintenance cost | Total cost of ownership (5 years) |

| Purchase all new devices | Long term mass production/high-precision demand | 100% | Centre | Rising-falling |

| Used equipment | Short term projects/testing validation | 30%~50% | Tall | Lower |

| Leasing equipment | Temporary orders/technical iteration period | 0 | Rising-falling | Minimum |

- Prioritize long-term needs: Choose to purchase all new equipment to balance initial investment with long-term returns.

- Short-term/ pilot production demands: Preference to leasing equipment to avoid financial risk, use of second-hand equipment as an alternative if budget allows.

- Core principles: match the most optimal combination of cost input resource flexibility according to production size precision requirements requirements and speed of technical iteration.

What are the differentiated competitive advantages of LS company?

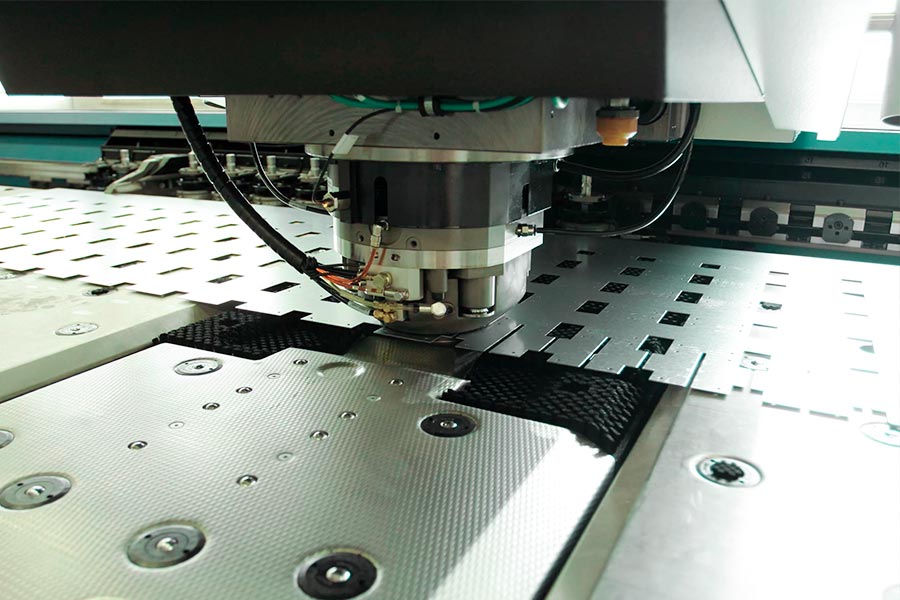

1.Technology integration: CNC+blanking collaboration: through online platform to achieve seamless integration of design and production, utilizing CNC precision processing to optimize mold details, shorten development cycles.

2.High precision, high complexity manufacturing: equipped with high speed precision punching machines and high precision die, falling die is durable, does not affect quality. To meet the strict requirements of high-precision micrometer level tolerances in electronics and medical devices.

3.Material flexibility: Covers common metals such as carbon steel, aluminum alloy alloy, titanium alloy, and provides surface treatment (plating, spraying) for enhanced functionality. Optimization technology of high strength steel or corrosion resistant material to improve product yield.

4.Customization and Rapid Response: Led by Nick Zhang, the company provides customized modular mold design or rapid replacement solutions to reduce long-term production costs for customers and support flexible transitions from single piece to mass production. Technical support response time is less than 4 hours and critical spare parts are well stocked (e.g. convex/concave molds contingency plan).

Summary

Mastering blanking process, especially the precision of metal punching, is an important challenge and core technology of metal forming technology. Blanking, as one of the basic methods of metal processing, requires a thorough understanding of various factors in the punching process, such as mold type, material characteristics, process parameters, etc, in order to ensure the precise size and excellent surface quality of the final punch. The combination of blanking technology and numerical control technology can balance efficiency and complexity. By fine-tuning these factors, the precision of punched parts can be effectively improved, and the need for high-precision parts can be met, thus promoting the sustainable development of metalworking industry.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.Why is metal blanking accuracy important to our products?

High precision punch can guarantee the stability and reliability of the product and reduce assembly problems caused by size deviation. At the same time, it can also improve the aesthetics and service life of the products and enhance the competitiveness of the market.

2.What happens if the precision of metal punch is not up to standard?

If the accuracy of the hardware punch does not meet the standard, it will lead to product assembly difficulties, performance degradation, and even cause safety hazards. At the same time, it will increase the cost of production and waste rate, and reduce the economic efficiency of enterprises.

3.What is the relationship between the precision of metal blanking and the cost of production?

There is a connection between the two. While high-precision blanking equipment and molds may increase initial investment costs, in the long run they can reduce production costs by improving product quality, reducing scrap and rework rates. Therefore, it is of great significance to control the precision of metal blanking to reduce production cost and improve the economic efficiency of enterprises.

4.What is the difference between punching accuracy of ordinary steel and aluminum alloy?

Steel has high hardness, easy deformation, high tonnage requirements for equipment and large die gaps. Aluminum alloy has a soft texture, good ductility, easy burr, fine lubrication and small clearance.

Resource