The blanking process is a fundamental technique in metal manufacturing, essential for producing high-precision components across various industries. LS Hardware Tech Co., Ltd stands out as a leader in this field, leveraging its years of expertise to deliver exceptional quality and efficiency. In this article, we delve into the mechanics of the blanking process, explore its various applications, and highlight LS's latest product - the Precision Fit Gear Housing.

Blanking is a manufacturing process where a punch and die are used to cut flat sheet metal into desired shapes. This method is predominantly used for creating mass-produced components with consistent quality. A key advantage of metal blanking is its ability to produce precise parts with smooth edges, making it an ideal technique for industries that demand precision. In fact, the blanking die and blanking machine utilized in this process enable manufacturers to meet exact specifications while minimizing material waste.

In the realm of manufacturing processes, understanding the nuances of blanking vs punching is crucial. While both involve cutting materials, punching typically refers to creating holes, whereas blanking focuses on cutting the outer shape, or "blank." Each process has its strengths and is selected based on the requirements of the component being manufactured.

LS Hardware Tech Co., Ltd, under the visionary leadership of Mr. Nick Zhang, has positioned itself as a trusted name in high-precision parts production. With over 20 years of experience and a foundation of engineering excellence, LS provides innovative solutions to more than 5,000 clients globally. Their ISO 9001:2015 certification attests to their commitment to quality, reinforcing their status as a premier partner for industries ranging from automotive to aerospace.

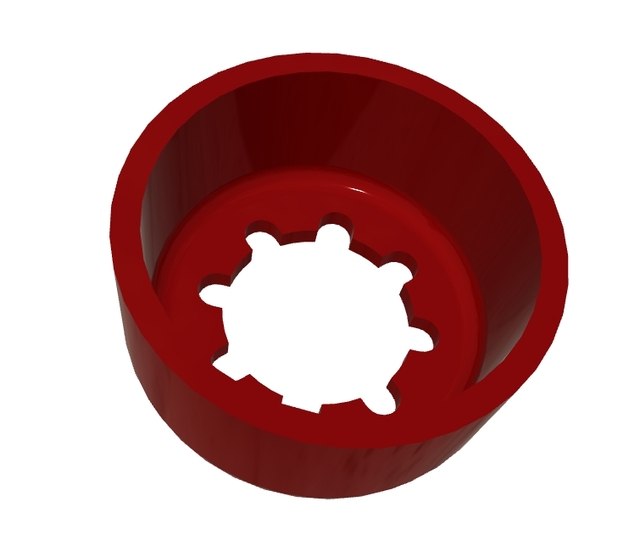

One of LS's flagship products exemplifying their manufacturing prowess is the Precision Fit Gear Housing. This robust component is crafted using a precision blanking process, ensuring exceptional accuracy in each piece. The gear housing is made from high-grade red polymer, known for its durability and resilience, particularly in extreme conditions. Its aesthetically pleasing red finish enhances visibility, a crucial factor in complex installations where quick identification is often necessary.

The Precision Fit Gear Housing is not just about looks; it's engineered for performance. At its heart lies a carefully designed internal gear structure, featuring precision-cut teeth for smooth operation and longevity. This meticulous design ensures seamless integration with various gear systems, enhancing the efficiency and lifespan of the machinery in which it is installed. Ideal for automotive, industrial, and robotic applications, this gear housing promises reliability and top-notch performance.

Steel blanking is a significant aspect of LS's manufacturing processes, facilitating the production of components like the Precision Fit Gear Housing. The process not only offers precision but also the durability required for high-stress environments. Steel's strength and flexibility make it an excellent choice for manufacturing components subjected to mechanical stress, ensuring that products stand the test of time.

The company's commitment to staying at the forefront of blanking in manufacturing is evident in their state-of-the-art factory. Equipped with over 100 high-end machining centers, LS achieves production efficiency that few can match. This infrastructure enables the company to cater to clients in more than 150 countries and regions worldwide, offering solutions ranging from prototypes to mass production.

In conclusion, the blanking process is pivotal in the manufacture of high-precision components, and LS Hardware Tech Co., Ltd has mastered the art of this technique. Their deep understanding of the process, combined with cutting-edge technology and an unwavering dedication to quality, positions them as leaders in the industry. Products like the Precision Fit Gear Housing are a testament to their innovation, reflecting a blend of functionality and style. As LS continues to enhance its capabilities, it remains an invaluable partner to industries seeking reliable and advanced manufacturing solutions. By choosing LS, clients are guaranteed components that meet the highest standards, enabling them to bring their ideas to life with confidence.

Mastering the Blanking Process: Manufacturing Excellence

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.