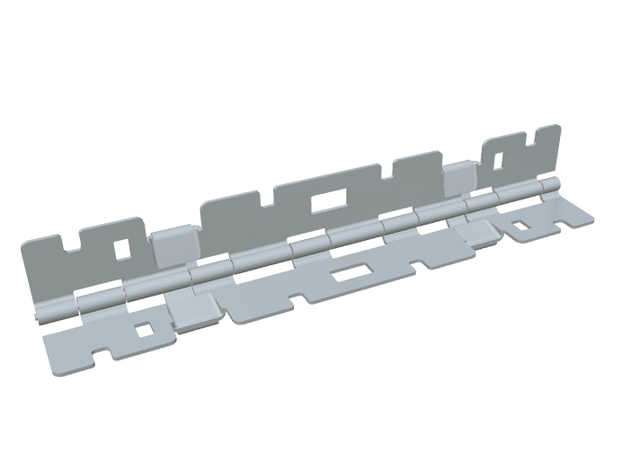

The blanking process is integral to the manufacturing of high-precision parts, catering to various industries like automotive, medical devices, consumer electronics, aerospace, and industrial equipment. This essential metal fabrication method involves the cutting of flat material, typically sheet metal, into a desired shape. In the world of mechanical engineering, the blanking process is indispensable, leading to the creation of precision gears and components used in numerous applications.

Understanding the nuances of the blanking process is crucial, particularly for manufacturers seeking to achieve high-quality results in sheet metal blanking and metal blanking operations. Blanking die is a key element in this process, determining the specific shape and size of each cut. Unlike punching, which leaves behind a sheet with holes, the blanking process focuses on creating the blank itself. This results in a clean, precise output that forms the backbone of subsequent manufacturing stages.

LS Hardware Tech Co., Ltd, a leader in the hardware and plastic parts industry, has harnessed the power of the blanking process to produce a stellar range of gear solutions. Their products are crafted with superior finesse and functionality, ensuring the utmost performance for various industrial applications. For over 20 years, LS has excelled in delivering innovative manufacturing solutions, led by Mr. Nick Zhang and his team of experienced engineers. With a strong commitment to quality and efficiency, LS serves clients in over 150 countries, setting a global standard for excellence.

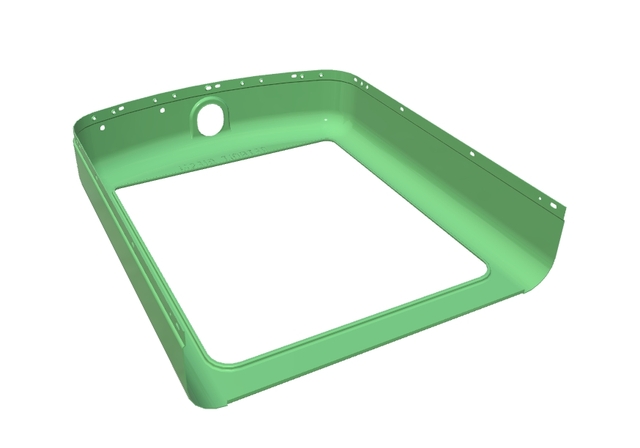

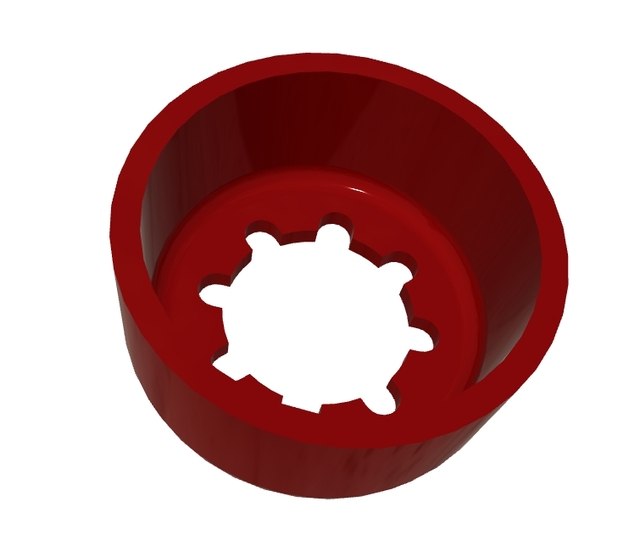

Among LS's offerings are meticulously crafted precision gears, each designed to meet the demands of specific engineering applications with unmatched efficiency. The spur gear, for instance, is impeccable in its straightforward performance, minimizing power loss in high-speed, low-torque scenarios. Helical gears, another of LS's innovative solutions, offer a quieter operation and increased torque capacity due to their angled teeth, making them ideal for situations where noise reduction is key.

In applications requiring smooth transmission and higher load capacity, LS's spiral bevel gears stand out. These gears deliver right-angle power transmission while reducing noise, a testament to the precision engineering that goes into each product. Likewise, straight bevel gears provide smooth motion and high durability for intersecting shafts, exemplifying the simplicity and efficiency that LS Hardware Tech Co., Ltd is renowned for.

Equally remarkable is the company's worm gear, perfect for situations necessitating substantial gear reduction. With its self-locking mechanism, it combines safety with efficiency, ensuring quiet operation while preventing back-driving. Additionally, LS’s gear rack is indispensable for those aiming to convert rotational motion into linear motion, offering precise control across varied mechanical applications. The internal gear rounds off LS's comprehensive catalog, offering a compact solution for planetary gear systems needing high efficiency and stability in space-constrained environments.

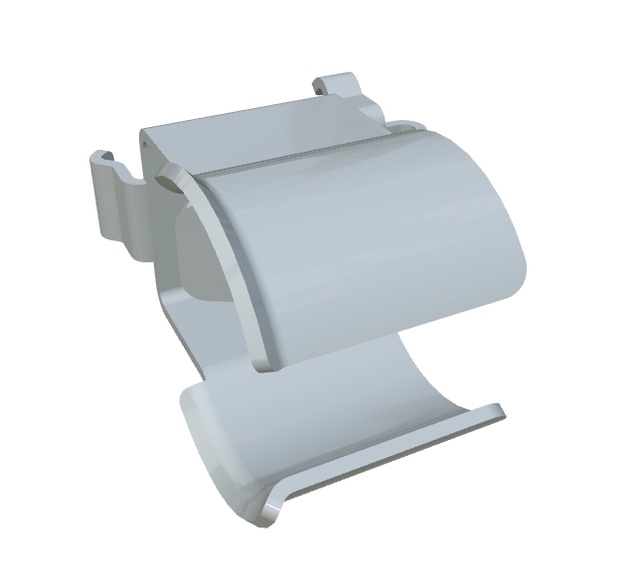

Further showcasing LS's dedication to innovation is the Smart Home Sensor. Designed with aesthetics and functionality in mind, this sleek device seamlessly integrates into any room. Encased in a glossy white finish, the sensor offers precision-driven enhancements to living spaces, equipped with cutting-edge detection technology and intelligent connectivity. Offering real-time updates and insights, it elevates the home environment while ensuring optimized comfort and security.

The blanking process and the meticulous craftsmanship at LS Hardware Tech Co., Ltd are pivotal to the creation of such high-caliber products. This company's emphasis on quality and precision is reflected in their ISO 9001:2015 certification, ensuring that each product meets stringent international standards. By leveraging over 100 high-end machining centers, LS guarantees high production efficiency and top-quality outcomes, underscoring their role as a trusted partner for major factories globally.

Ultimately, LS Hardware Tech Co., Ltd is committed to delivering innovative solutions that bring clients' ideas to life, constantly adapting to meet the evolving needs of the market. This dedication to technological advancement cements their position at the forefront of the industry, providing a full range of services from prototype development to mass production. Through the integration of processes like blanking, LS remains a beacon of innovation and reliability, empowering their clients to achieve unparalleled success across diverse industrial applications.

Mastering the Blanking Process in Metal Fabrication

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.