In the evolving landscape of manufacturing, **progressive die stamping** has emerged as a cornerstone of high-precision production processes. With its roots firmly embedded in innovation and efficiency, this technique is pivotal for delivering high-volume stamping solutions that are both adaptable and reliable. Among the vanguard of companies leveraging this technology is LS Hardware Tech Co., Ltd, a trailblazer in the domain of metal stamping services and custom metal fabrication.

Progressive die stamping is a metalworking method widely adopted for its capability to produce complex parts at a high volume with precision and consistency. The process involves multiple metal stamping operations, such as cutting, bending, and piercing, performed in one fluid sequence through a series of dies. This allows for automation and faster production, significantly enhancing productivity and reducing manufacturing costs. Progressive die design is central to the success of this process, as it determines the efficiency and quality of the output. Companies like LS Hardware Tech Co., Ltd, with their expertise in stamping die manufacturing, ensure that the dies are meticulously crafted to meet specific client needs.

LS Hardware Tech Co., Ltd stands at the forefront of offering specialized metal stamping services, boasting a robust infrastructure characterized by over 100 high-end machining centers. This allows them to cater to the ever-growing demands of industries ranging from automotive to aerospace. Founded by industry luminary Mr. Nick Zhang, LS has spent over two decades honing their craft, amassing a client base of more than 5,000 satisfied partners around the globe. Their ISO 9001:2015 certification underscores a commitment to quality and precision, essential factors when undertaking high-volume stamping and custom metal fabrication projects.

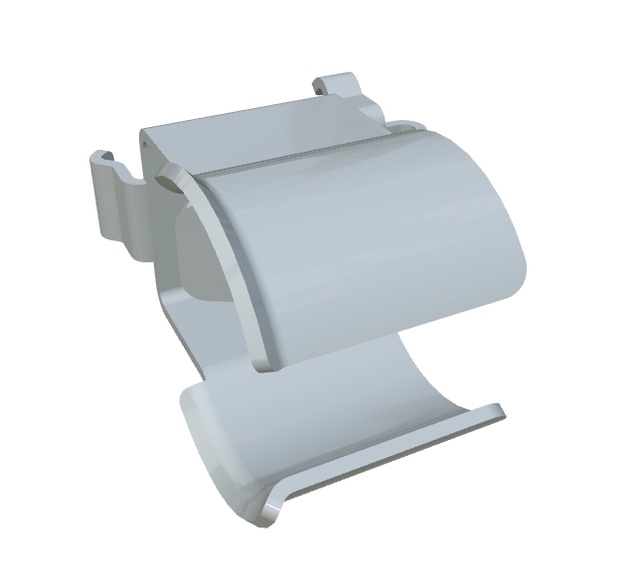

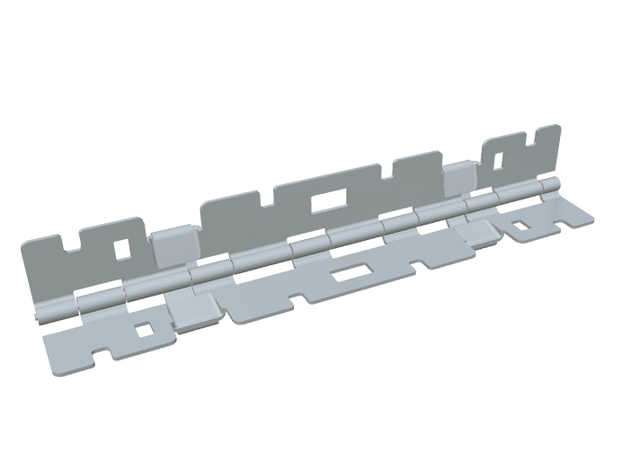

One of the flagship products from LS Hardware Tech is the cutting-edge Precision Grooved Rail System. This innovative solution is a testament to their prowess in precision metal stamping and product design. Crafted from top-grade materials, the rail system is not just robust but also adaptable. Its intelligently designed grooves enhance grip and flexibility, ensuring that the system fits seamlessly into varied industrial applications. Designed with efficiency in mind, the rail's evenly spaced holes simplify customization and allow for a quick, hassle-free integration into existing setups. This design drive is a direct reflection of the LS commitment to superior product engineering through automated stamping solutions.

The Precision Grooved Rail System embodies the company's mission to deliver innovative manufacturing solutions that empower clients. By continuously advancing their capabilities and refining their processes, LS Hardware Tech positions itself as a strategic ally in bringing complex ideas to fruition. Their focus on precision metal stamping techniques guarantees top-tier products that rise to meet the multifaceted requirements of modern industrial applications.

The journey of LS Hardware Tech from a nascent entity to a global industry leader illustrates the transformative power of continuous improvement and technological adoption. It’s companies like LS Hardware Tech that exemplify the strides being made in stamping die manufacturing and progressive die design, forging paths to newer heights in production efficiency and product quality. With a commitment to excellence, LS continues to set benchmarks in metal stamping services, tirelessly expanding their influence to more than 150 countries and regions worldwide.

In conclusion, the role of progressive die stamping in today's manufacturing ecosystem cannot be underestimated. It represents a fundamental shift towards more efficient, high-volume production that meets the precise specifications modern industries demand. LS Hardware Tech Co., Ltd, through their bespoke solutions such as the Precision Grooved Rail System, demonstrates not just a mastery of this art but also a clear vision towards the future of manufacturing—a future where precision, reliability, and innovation chart the course for ongoing success.

Mastering Progressive Die Stamping: A Key to Precision

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Progressive Die Stamping, Metal Stamping, Deep Draw Stamping, Hydroforming, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.