Insert molding is revolutionizing the manufacturing industry, offering a versatile and reliable method for creating composite parts by embedding inserts into molten plastic during the molding process. This innovative technique has gained popularity due to its unique ability to combine metal or other materials with plastic, leading to enhanced product features and expanding its applications across various industries.

The insert molding process is a specialized form of injection molding that involves placing inserts—often metal components like nuts, screws, or mesh—into a mold cavity and then injecting plastic resin around them. This method not only streamlines production but also results in components that embody the strength of both materials, with the plastic securely encapsulating the inserts. This capability is particularly beneficial for manufacturers seeking to produce parts that require integrated fasteners or are designed for electrical or structural applications, hence the rising interest in custom insert molding.

In the realm of plastic insert molding, companies are opting for this technique to address demanding manufacturing needs efficiently. The advantages of insert molding are manifold. Notably, it reduces assembly time and the costs associated with traditional post-molding assembly processes. Furthermore, insert molding enhances the strength and reliability of the assembled product, as the bond formed during the process is generally stronger than mechanical assembly alone. These insert molding advantages are key in industries such as automotive, electronics, and consumer goods, where durability and precision are paramount.

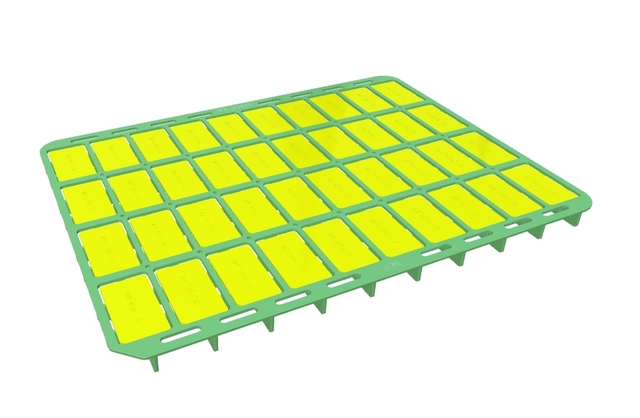

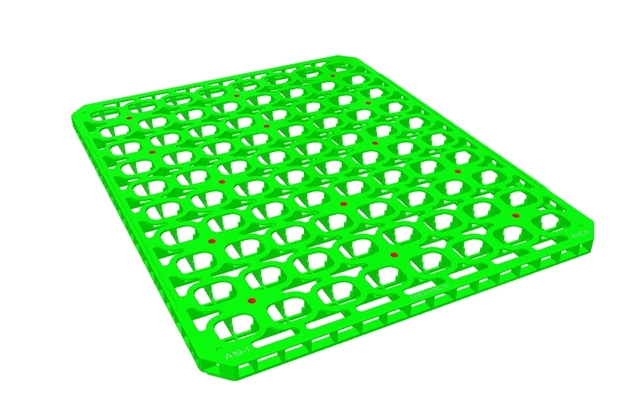

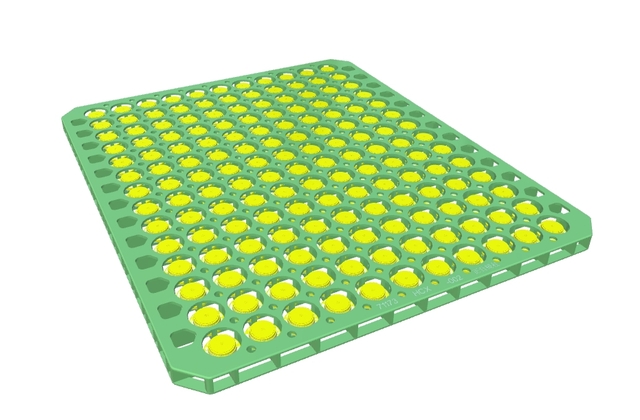

The application is further exhibited in products like the eco-friendly grid pallet system, which benefits from insert molding techniques to maximize its efficiency and sustainability. Engineered with a sophisticated grid pattern, each segment of this vibrant green pallet features precisely placed cut-outs enhanced by red accents, bolstering stability and preventing slippage with various loads. This strategic design not only improves functionality but also aligns with environmental objectives. Combined with high-durability and lightweight construction, the pallet exemplifies how insert molding can play a crucial role in modern logistics by providing smart, responsible solutions that support both heavy-duty usage and sustainability goals. Through insert molding applications, manufacturers like those creating the innovative grid pallet system can craft products tailored to meet specific needs while adhering to eco-conscious principles.

Insert Molding: Techniques, Advantages, and Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Understanding the Insert Molding Process: Advantages and Applications

Insert Molding: Revolutionizing Electronic Enclosures

Revolutionizing Products with Insert Molding Techniques

Insert Molding: Revolutionizing Modern Manufacturing

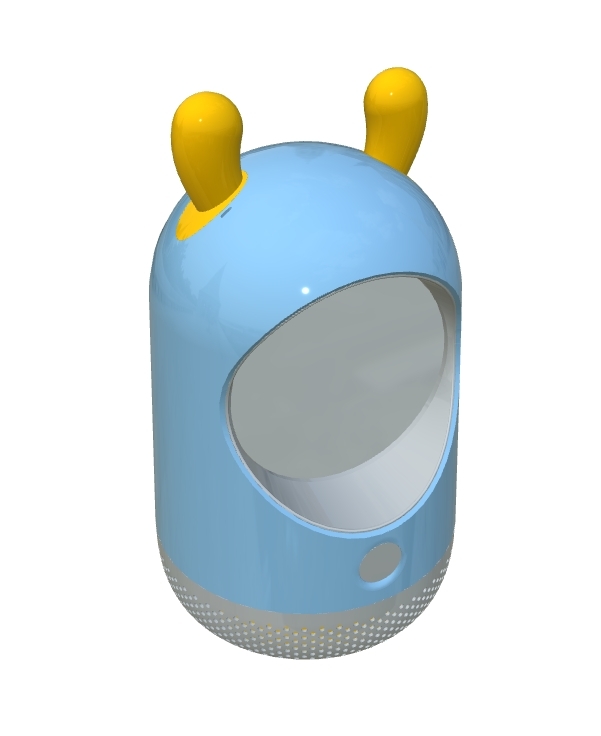

Insert Molding: Revolutionizing Smart Interactive Buddy

Insert Molding: Revolutionizing Plastic Manufacturing

Insert Molding: Techniques, Advantages, and Applications

Revolutionizing Manufacturing with Insert Molding Technology