Key Features

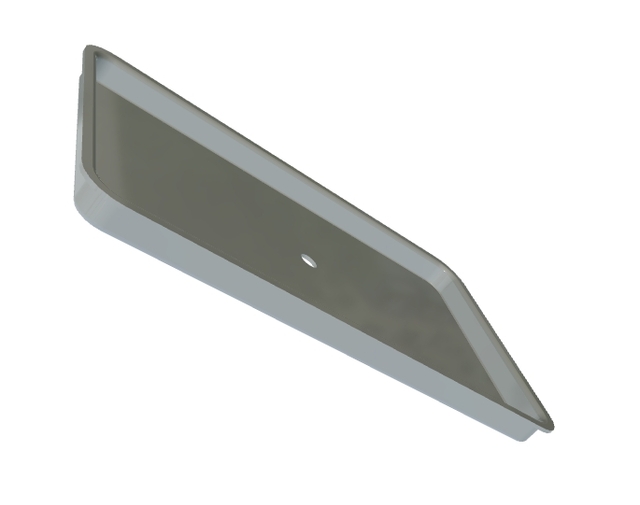

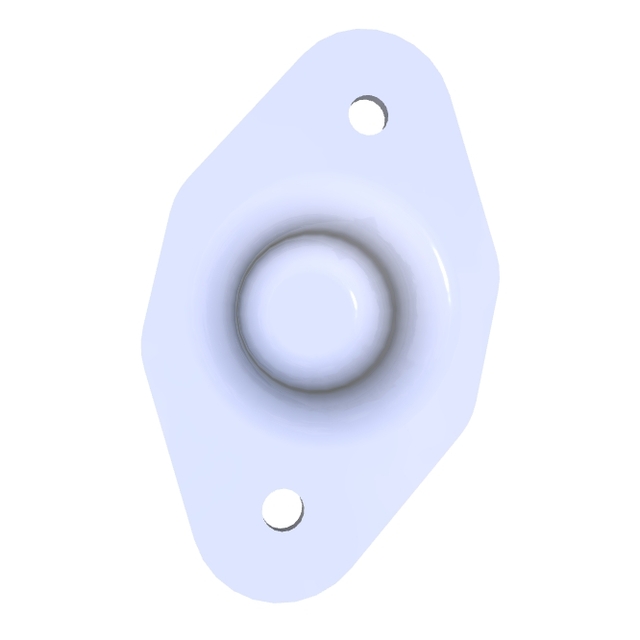

The CNC-machined mounting plate offers industry-leading performance, crafted for precision and durability. Its key features include:

- High Dimensional Accuracy: Designed with tight tolerances, this plate ensures a perfect fit for precision applications. Learn more about our 5-axis CNC machining capabilities.

- Lightweight Structure: Engineered to reduce weight without compromising strength, making it ideal for various industries like aerospace.

- Pre-Drilled Holes: Simplifies installation, reducing production time. Explore our CNC turning services for additional customizations.

Each feature ensures the mounting plate’s adaptability to high-performance industries.

Applications

This CNC-machined mounting plate is widely used across diverse fields, including:

- Aerospace: Provides lightweight yet strong mounting solutions for avionics and structures. Check out our aerospace solutions.

- Medical Devices: Ideal for precision components in diagnostic and therapeutic equipment. Learn about our medical device machining capabilities.

- Robotics: Perfect for automation systems requiring stable and reliable components. Read more about our robotics and automation solutions.

- Industrial Equipment: Ensures durability and strength under extreme operating conditions. Explore our industrial equipment solutions.

These applications highlight its versatility and precision across industries.

Manufacturing Process

Material Selection

- High-quality materials are chosen to meet application demands, ensuring durability and efficiency. See our material selection guide.

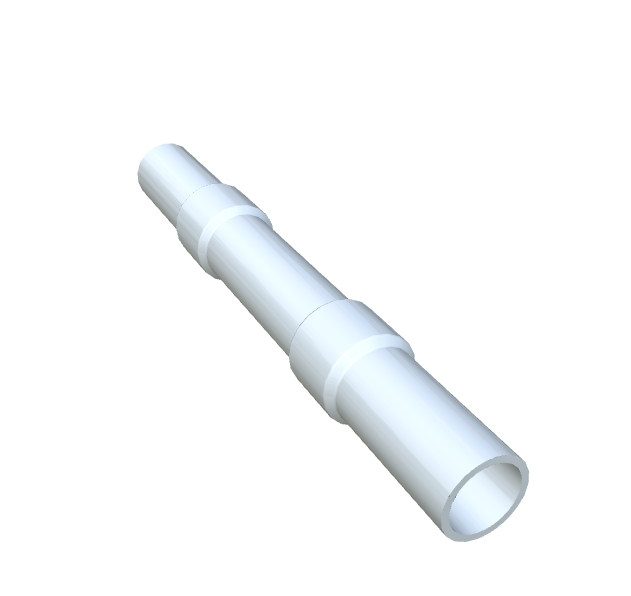

CNC Machining

- Advanced CNC milling and turning processes create parts with exact specifications. Explore our CNC milling services for precise components.

Surface Finishing

- Techniques like anodizing and powder coating are available for improved appearance and durability. Learn about our surface finishing services.

Quality Assurance

- Rigorous quality control ensures the part meets industry standards. Check out our quality control procedures for more details.

Our streamlined processes ensure consistent and high-quality output.

Materials

The mounting plate can be manufactured using a variety of materials, including:

- Aluminum: Lightweight and corrosion-resistant, perfect for aerospace and automotive applications.

- Stainless Steel: Offers excellent heat resistance and tensile strength for medical devices and industrial equipment.

- Titanium: Combines lightweight properties with exceptional strength, suitable for high-performance industries.

- Plastics: Materials like PEEK and polycarbonate provide lightweight, insulating options for electronics.

Selecting the right material enhances durability, functionality, and performance for specific uses.

Why Choose Us?

Custom CNC Parts

Get tailored solutions with our custom CNC machining services to meet your project requirements.

Fast CNC Quotes

Receive accurate quotes quickly through our quote request system.

Expertise Across Industries

With experience in aerospace, robotics, and medical devices, we deliver solutions that excel in precision.

Advanced CNC Technology

Our state-of-the-art 5-axis CNC machining and CNC lathe services ensure tight tolerances and superior finishes.

Comprehensive Support

We offer solutions for every step, from prototyping to assembly.

Partner with us for all your precision machining needs, and experience unparalleled quality and service.