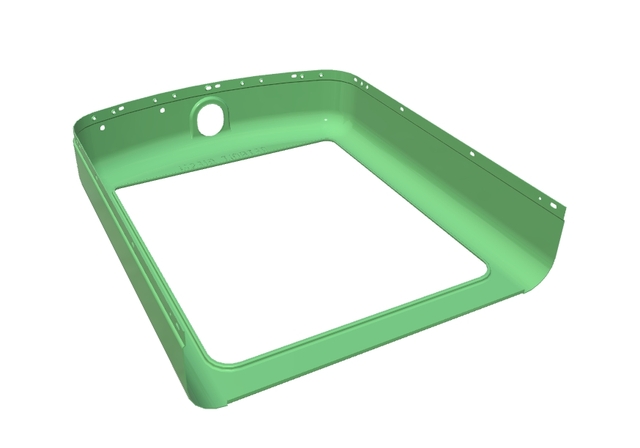

The art and science of the blanking process have revolutionized the way we approach manufacturing, especially in the realm of metalworking. This intricate method, central to many industries, involves cutting sheet metal into precise shapes and sizes for further processing. Known as the **blanking process** in industrial jargon, it stands as a pivotal operation in transforming raw materials into a myriad of functional components.

In the backdrop of the metalworking industry, **metal blanking** emerges as a fundamental technique. It is celebrated not only for its efficiency but also for its precision in creating consistent and uniform pieces. This process is executed using a *blanking machine* that expertly shears the desired shapes out of larger sheets of metal. These machines are integral to the *blanking operation*, as they ensure meticulous execution and high throughput, which industries increasingly rely on.

**Sheet metal blanking** is another critical aspect of this process. Given the burgeoning demand for high-quality metal components in sectors such as automotive and aerospace, companies like LS Hardware Tech Co., Ltd are leveraging these techniques to stay ahead. Founded by Mr. Nick Zhang alongside a team of brilliant engineers, LS Hardware Tech boasts over two decades of prowess in the field. The company prides itself on its best-in-class solutions, having served over 5,000 clients across diverse industries.

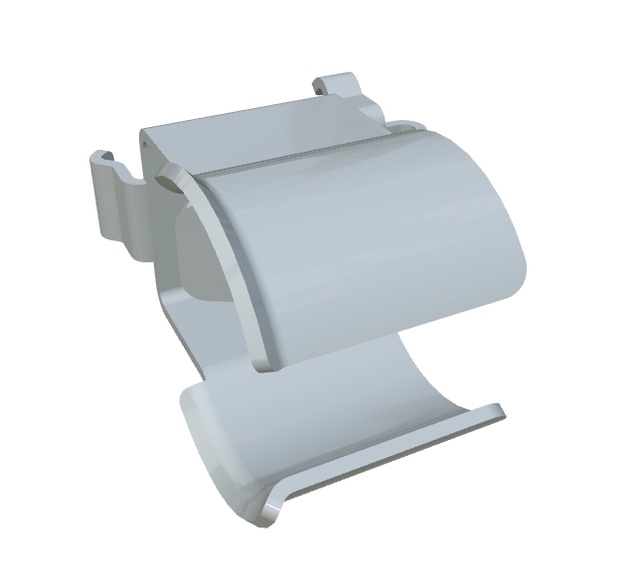

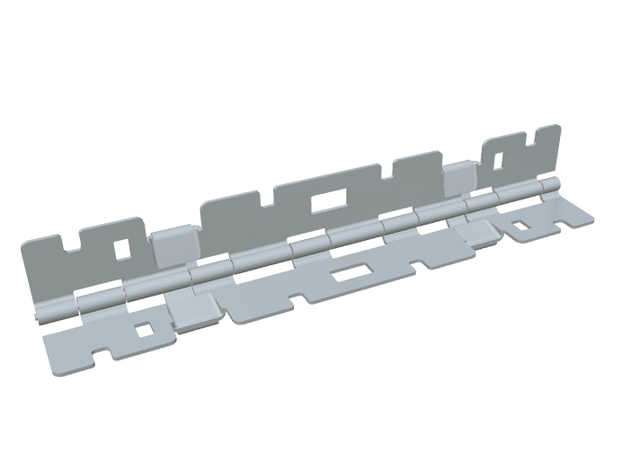

Their innovative approach is evident in their latest product offering: the Modular Design Hinges. Crafted with a keen eye for detail, these hinges are the culmination of what precise **blanking die design** can achieve. Intelligently engineered, these hinges are constructed from high-quality metal, reminiscent of the astute craftsmanship Nick Zhang champions. The design includes numerous cut-outs and flexible sections, testament to the capabilities of advanced *blanking tools* and their role in achieving bespoke customization.

Further celebrating the synergy between form and function, the hinges’ sleek design is accentuated by a uniform matte finish. This modern elegance does not detract from their primary function, instead augmenting their appeal. These hinges are tailored for easy integration into a variety of applications, from cabinetry to industrial machinery. Professionals and hobbyists alike find that these are not just hinges, but an intelligent solution for seamless, reliable motion technology. Such innovations are a nod towards how **automated blanking** has significantly evolved, allowing manufacturers to achieve enhanced precision and efficiency.

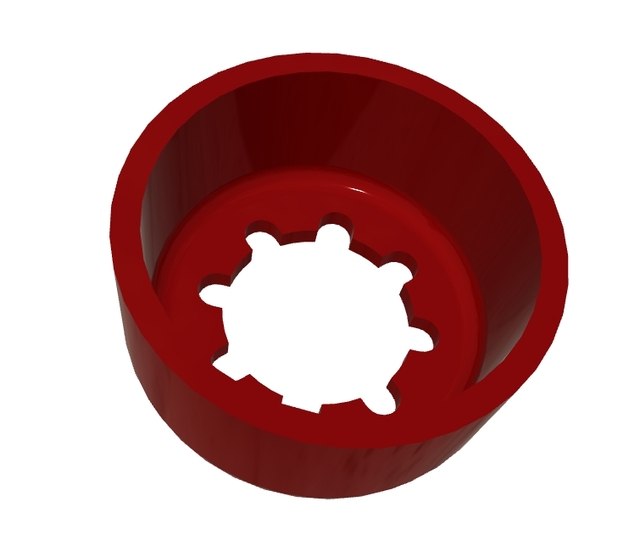

The facilities at LS Hardware Tech Co., Ltd have played a crucial role in their success. Their factory, brimming with over 100 high-end machining centers, ensures that high production efficiency and top-quality products remain constant outputs. This commitment to excellence is validated by their ISO 9001:2015 certification, which echoes their dedication to stringent quality standards and reliable deliverables.

LS’s state-of-the-art technologies not only cater to domestic needs but also fulfill international demands, with their services extending to more than 150 countries and regions worldwide. Whether in the automotive, medical, consumer electronics, or aerospace sectors, the company is poised to meet a wide spectrum of needs, from developing intricate prototypes to fulfilling mass production orders efficiently.

Their Modular Design Hinges are positioned to be a game-changer for industries seeking innovative connectivity solutions. They offer the promise of strength, versatility, and aesthetic appeal, making them ideal for modern design needs. By channeling their expertise in **blanking process** and related technologies, LS Hardware Tech Co., Ltd continues to empower clients to bring their ideas to life, consistently pushing the envelope in terms of what can be achieved through metalworking innovation.

In conclusion, the blanking process remains a cornerstone of manufacturing, allowing for the creation of precise and innovative components that drive various industries forward. Companies like LS Hardware Tech Co., Ltd not only exemplify mastery over this technique but also highlight the potential of what skilled execution and dedication to quality can bring to the global stage. With continuous improvements and adherence to the highest standards, they stand as a beacon of innovation and reliability in the manufacturing landscape.

Exploring the Blanking Process: Key to Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering the Blanking Process: Precision in Metal Blanking

Blanking Process: Mastering Metal Blanking and Tool Design

Understanding the Blanking Process in Modern Manufacturing

Exploring the Blanking Process: Key to Modern Manufacturing

Exploring the Blanking Process: Efficiency and Innovation

Mastering the Blanking Process: Manufacturing Excellence

Exploring the Precision of Blanking Process in Modern Manufacturing

Mastering the Blanking Process in Metal Fabrication