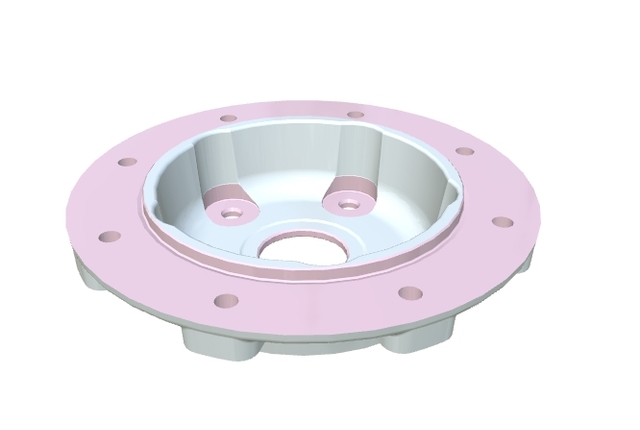

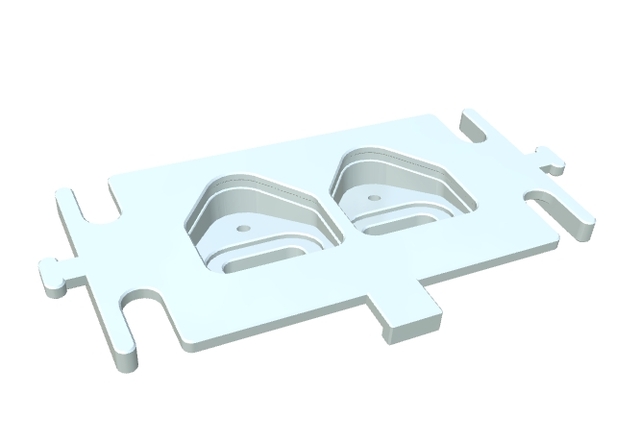

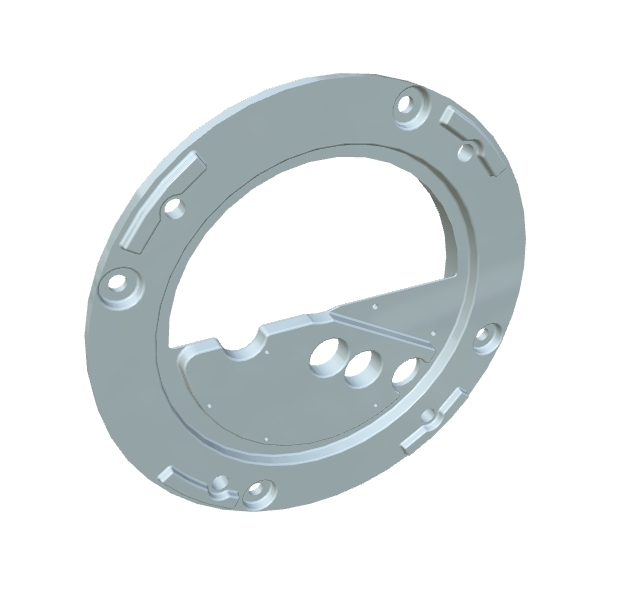

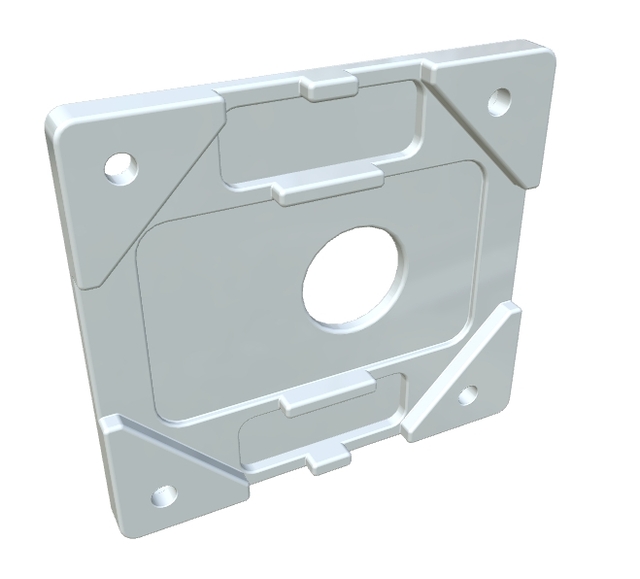

In the ever-evolving world of manufacturing, **die casting** emerges as a pivotal metal casting process that leverages high pressure to intricately shape metals like aluminum and zinc. This sophisticated casting technology has become essential across numerous industries, providing a streamlined, efficient means of production for a variety of high-quality components.

**High pressure casting** and its variants such as aluminum die casting and zinc die casting, play critical roles in creating components that demand precision and durability. These methods are particularly valued for their ability to produce high-volume die casting outputs while maintaining stringent quality standards. Additionally, pressure die casting stands out for its ability to deliver exceptionally detailed and precise molds, ensuring every product crafted meets exceedingly high-quality benchmarks—perfect for industries that require precision die casting.

The advantages of pressure casting are numerous. Its ability to produce complex parts with minimal machining, offer enhanced mechanical properties, and provide a smooth surface finish truly sets it apart. Moreover, the use of casting technology allows for efficient high-volume production which is crucial for meeting the substantial demands of modern manufacturing sectors.

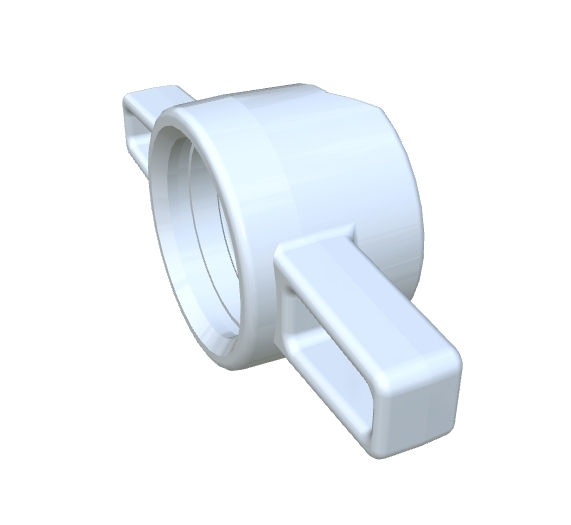

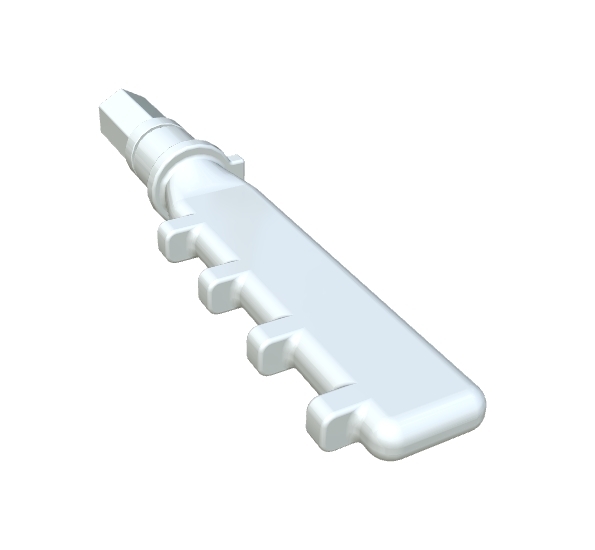

In complement to the robust world of die casting, innovative products like the 3D-printed coupling nut demonstrate the cutting-edge applications of modern material processing. This sleek, white coupling nut, crafted with precision from high-grade plastic, exemplifies the integration of state-of-the-art engineering with practical application. Its dual lugs are designed to offer enhanced grip, making hand-tightening an effortless task—a true testament to its ease of use and functionality.

The coupling nut effortlessly merges aesthetics and performance, marrying the minimalist elegance of its cylindrical body with the robust functionality required in various industrial settings. It is ideal for creating secure connections, providing reliable fastening solutions for pipes or tubing. Thus, not only does it spotlight superior engineering but also embraces a contemporary style that complements both industrial and DIY projects alike.

In summary, both die casting and cutting-edge components like the 3D-printed coupling nut reflect the way modern material processes are transforming industries. They not only highlight the synergy between precision engineering and durability but also underscore the potential for merging technological advancements with practical innovation. Such developments ensure that die casting and related products continue to offer invaluable advantages, upholding their significance in today's competitive market.

Die Casting: Precision Technology Revolutionizing Metalwork

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sand Casting, Metal Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.