In the world of manufacturing, **deep draw stamping** emerges as a critical process, characterized by its remarkable ability to form complex shapes with high precision. As a key component in various industries, deep draw metal stamping is an indispensable technique that brings innovation and efficiency to the forefront of modern machinery production.

Deep draw forming, also known as metal deep drawing, involves the transformation of flat sheet metal into three-dimensional shapes through a die. This method is distinguished by its capacity to produce intricate parts without compromising on structural integrity. The deep drawing process offers unparalleled advantages, such as improved material utilization, reduced weight, and enhanced strength, making it particularly valuable in sectors like automotive and aerospace.

One of the leading pioneers in this domain, LS Hardware Tech Co., Ltd, stands out for its exceptional contributions to the field. Founded by the visionary Mr. Nick Zhang, LS Hardware embodies a legacy of over 20 years of expertise in manufacturing hardware and plastic parts. The company's commitment to quality and innovation has earned it a reputation as a trusted partner to major factories across China and beyond, extending its services to over 150 countries worldwide.

The strength of LS Hardware lies in its impressive infrastructure, boasting over 100 high-end machining centers that drive its high production efficiency and top-quality products. The company's ISO 9001:2015 certification further underscores its dedication to maintaining the highest standards in manufacturing. LS Hardware's specialization in the production of high-precision parts caters to industries like automotive, medical devices, consumer electronics, aerospace, and industrial equipment, seamlessly bridging the gap between concept and creation.

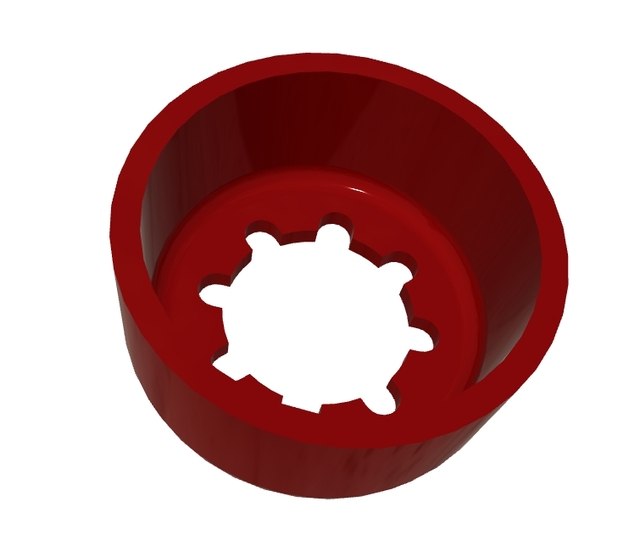

Among LS Hardware's exceptional product lineups is the Red Precision Gear Holder, a testament to the possibilities unlocked through custom deep drawn parts. This sleek and innovative component is designed for modern machinery, featuring a robust design with six integrated slots that ensure superior grip and compatibility with various gear systems. Crafted from high-strength materials, this gear holder boasts a vibrant red finish, merging durability with aesthetics.

Engineered with precision, the Red Precision Gear Holder optimizes performance and ensures seamless operation in complex mechanical applications. Whether for engineers or hobbyists, this component exemplifies the synergy between functionality and style, empowering users to enhance the efficiency of their machinery effortlessly.

The impact of deep draw stamping extends beyond mere production, influencing the capabilities and evolution of industries worldwide. Processes like automotive deep draw stamping drive innovation from the assembly lines of major automotive brands to the intricate components of medical devices that safeguard our health. Precision deep drawn components showcase the finesse with which everyday products are crafted, ensuring reliability and durability.

The enduring relevance of deep drawing process lies in its ability to adapt to the changing demands of technology and manufacturing. Continuous improvements in capabilities reflect LS Hardware's mission to deliver innovative manufacturing solutions that empower clients to bring their ideas to life. By staying at the forefront of technology, LS Hardware remains committed to meeting the evolving needs of its customers, providing efficient solutions that embody the highest standards of quality.

In conclusion, deep draw stamping serves as the backbone of modern manufacturing, defining the structure and efficiency of various industry sectors. LS Hardware Tech Co., Ltd's unwavering dedication to quality, precision, and innovation showcases how this intricate process translates into tangible results, enriching lives and shaping the future of technology. As industries continue to evolve, deep draw metal stamping will undoubtedly remain a cornerstone, driving progress and fostering collaboration across the globe.

Deep Draw Stamping: Revolutionizing Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Hydroforming, Deep Draw Stamping, Progressive Die Stamping, Blanking, Metal Stamping |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Deep Draw Stamping: Elevating Precision and Design

Deep Draw Stamping: Precision and Efficiency Redefined

Exploring Advanced Deep Draw Stamping Techniques for Precision Engineering

Deep Draw Stamping: Precision Solutions by LS Hardware Tech

Deep Draw Stamping: Revolutionizing Modern Manufacturing

Deep Draw Stamping: Precision & Applications

Deep Draw Stamping: Techniques & Precision Solutions

Deep Draw Stamping: Precision Solutions for Modern Industries