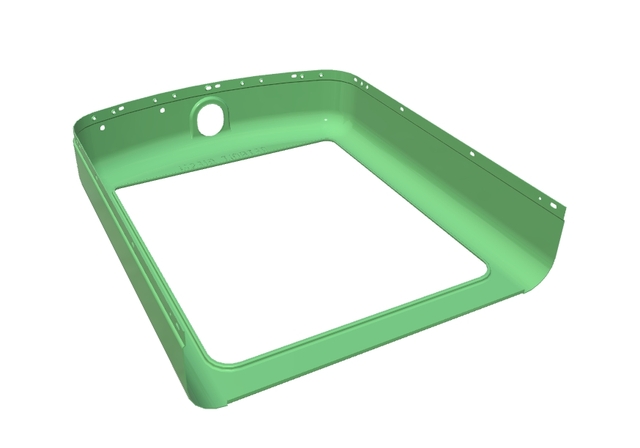

In the realm of cutting-edge manufacturing technologies, "deep draw stamping" emerges as a pivotal process in the fabrication of high-quality, precise metal components. LS Hardware Tech Co., Ltd, with over 20 years in the industry, excels in delivering solutions that elevate this metal forming technique to meet the dynamic needs of modern industries. The company’s latest product, the AeroEdgeline Shelf, embodies the essence of deep draw technology, reflecting sophistication in design coupled with robust functionality.

Deep draw stamping is an intricate stamping process that involves the radial drawing of a sheet metal blank into a forming die by the mechanical action of a punch. It is one of the industrial stamping techniques employed to create complex parts that are impossible to achieve through other metal forming methods. The hallmark of precision stamping is evident in LS Hardware Tech's approach, where die design plays a crucial role in ensuring consistency and superior quality of the end product.

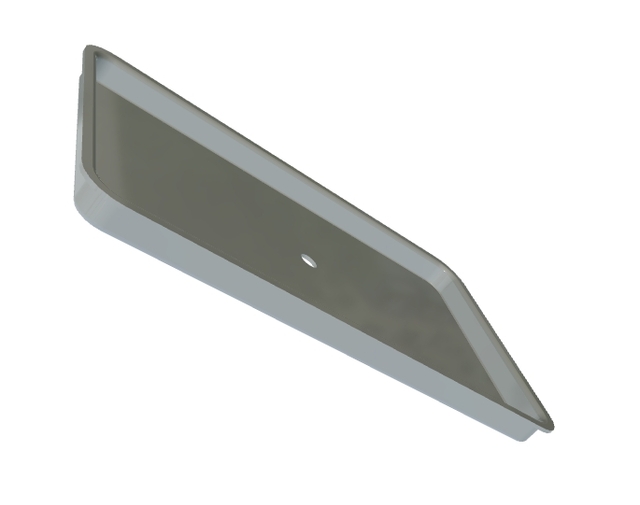

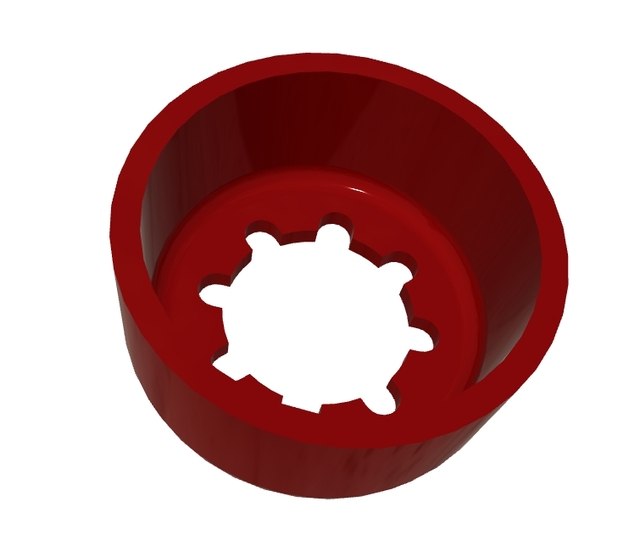

AeroEdgeline Shelf, an exemplification of custom metal parts, showcases this precision. Its sleek design is a testament to the meticulous metal forming process it undergoes, making it a perfect fit for contemporary studios, offices, and modern homes. Constructed from high-quality, lightweight materials, this shelving unit is not only durable but also accentuates any living space with its elegant yet minimalist aesthetic. The deep draw technology behind its creation enables the production of its aerodynamic edges, which flow seamlessly, adding both functional and visual appeal to any setting.

The LS Hardware Tech Co., Ltd's commitment to excellence is unwavering as they leverage deep draw stamping to serve over 5,000 clients globally. Their factory, equipped with more than 100 high-end machining centers, stands as a paragon of industrial efficiency, churning out high-precision parts that span across a multitude of sectors including automotive, aerospace, and consumer electronics. The AeroEdgeline Shelf is no exception, standing as a hallmark product that benefits from LS’s comprehensive understanding of the stamping process.

The importance of robust die design cannot be understated, as it forms the core of achieving precision in stamping. The integration of innovative technologies and the dedication to process improvement ensure that each product, such as the AeroEdgeline Shelf, not only meets but exceeds customer expectations in terms of quality and design. This is further exemplified by the subtle matte finish of the shelf, achieved through meticulous stamping, enhancing its visual appeal and versatility as a display for art, books, or ornamental items.

LS Hardware Tech's ISO 9001:2015 certification speaks volumes about their stringent quality control processes, ensuring each deep draw technology implementation is of the highest standard. Their global presence in over 150 countries showcases the trust and reliability they have built in the metal forming industry, with the stamping process being a cornerstone of their manufacturing prowess. The AeroEdgeline Shelf, while a reflection of modern aesthetics, is a result of the synergy of innovative design and precision stamping.

In conclusion, deep draw stamping is not just a manufacturing process but an art of transforming sheet metal into high-quality, functional products. LS Hardware Tech Co., Ltd, via their extensive expertise in metal forming and industrial stamping, brings to life products that are both innovative and durable. The AeroEdgeline Shelf is more than just a shelving unit; it is a symbol of precision stamping and the company’s unwavering commitment to quality and excellence. Whether you are an aficionado of design or in need of a functional addition to your space, the AeroEdgeline Shelf represents the epitome of what custom metal parts can achieve when backed by superior deep draw technology.

Deep Draw Stamping: Elevating Precision and Design

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Stamping, Progressive Die Stamping, Hydroforming, Deep Draw Stamping, Blanking |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Deep Draw Stamping: Elevating Precision and Design

Deep Draw Stamping: Precision and Efficiency Redefined

Exploring Advanced Deep Draw Stamping Techniques for Precision Engineering

Deep Draw Stamping: Precision Solutions by LS Hardware Tech

Deep Draw Stamping: Revolutionizing Modern Manufacturing

Deep Draw Stamping: Precision & Applications

Deep Draw Stamping: Techniques & Precision Solutions

Deep Draw Stamping: Precision Solutions for Modern Industries