As one of the earliest practical3D printing technologies, stereolithography has demonstrated its huge application potential in many fields since its development by Charles Hull in 1986. This technology uses laser beams to irradiate liquid photosensitive resin to solidify it, thereby building a three-dimensional entity layer by layer. So, what materials are used in stereolithography? TheLS teamwill take everyone into the ocean of material knowledge about stereolithography technology to find out. Let’s start learning today!

What Materials Are Used in Stereolithography?

Stereolithography mainly uses the following materials:

- Light-cured acrylic resin:This is one of the most commonly used materials in stereolithography and has the advantages of high transparency and fast curing speed. It can make transparent models, and upon demand, the body can be made of transparent resin for inspecting the interior of the prototype. However, it should be noted that the processed resin is usually translucent and requirespost-processingsuch as polishing and coating to make it transparent.

- Epoxy resin:Epoxy resin is also a commonly used material in stereolithography. It is usually combined with a cationic initiator to form a pure cationic photosensitive resin. This resin has the advantages of low viscosity, excellent weather resistance, low curing shrinkage, high cross-linking density, and high reactivity, so it can produce parts with high precision.

- Liquid crystal/light-curing resin:This is a resin formulated through a specific formula that combines the properties of liquid crystal and light-curing resin. This resin can achieve precise modulation of the existing liquid crystal morphology within the resin, and the orientation of the liquid crystal can be controlled by the directional polymerization of monomers or prepolymers with acrylate groups. Objects printed with this resin often have better tensile,bendingand impact properties than objects created with commercial resins.

- Polyurethane elastomer:Polyurethane elastomer is also used in stereolithography due to its excellent elasticity, strength and toughness as well as good biocompatibility and blood compatibility. Through light-curing 3D printing technology, high-precision molding of high-performance polyurethane elastomer can be achieved.

- Dental and Medical Resins:These resins are designed for medical and dental applications and are biocompatible and precise. They are often used to make medical devices such as dental models and surgical guides.

What Are the Chemical Components of SLA Resins?

Thechemical composition of SLA resinmainly includes the following parts:

1. Photopolymer

Photopolymers are the core components of SLA resins, and they are highly sensitive to ultraviolet radiation. Under the irradiation of ultraviolet light, the photopolymer can rapidly undergo a polymerization reaction and transform from a liquid state to a solid state, thereby forming a 3D printed solid structure.

2. Acrylic and epoxy resin

Acrylates and epoxy resins are common chemical bases in SLA resins.

- Acrylate:Acrylate resin has good photosensitivity and curing speed and is an important component ofSLA resin. They usually have higher transparency and lower viscosity, which is beneficial to the penetration of UV light and the flow of resin. However, acrylic resins may experience some shrinkage during the curing process, which may affect the accuracy and dimensional stability of printed parts.

- Epoxy resin:Epoxy resin has excellent mechanical properties and chemical stability and is another important basic ingredient in SLA resin. They typically have high strength and hardness, as well as good weather and chemical resistance. In SLA resin, the introduction of epoxy resin can further improve the performance of printed parts.

3. Additives

In order to improve the performance of SLA resin, variousadditives are often added to meet specific application needs. These additives may include:

- Pigments:Used to enhance the color expression of the resin so that the printed parts have the desired color.

- Toughening agent:used to improve the toughness and impact resistance of the resin to make printed parts more durable. The addition of toughening agents can effectively reduce cracks and fractures in the resin during the curing process.

- Heat-resistant agent:used to improve the thermal stability and heat distortion temperature of the resin, making it suitable for applications in high-temperature environments. The addition of heat-resistant agent can make printed parts maintain stable performance at high temperatures.

- Low-shrinkage additive:used to reduce the shrinkage of the resin during the curing process, thereby improving the accuracy and dimensional stability of printed parts. Low shrinkage additives can effectively reduce the internal stress and deformation of the resin after curing.

What are the material properties of SLA resin?

Thematerial properties of SLA resinmainly include the following points:

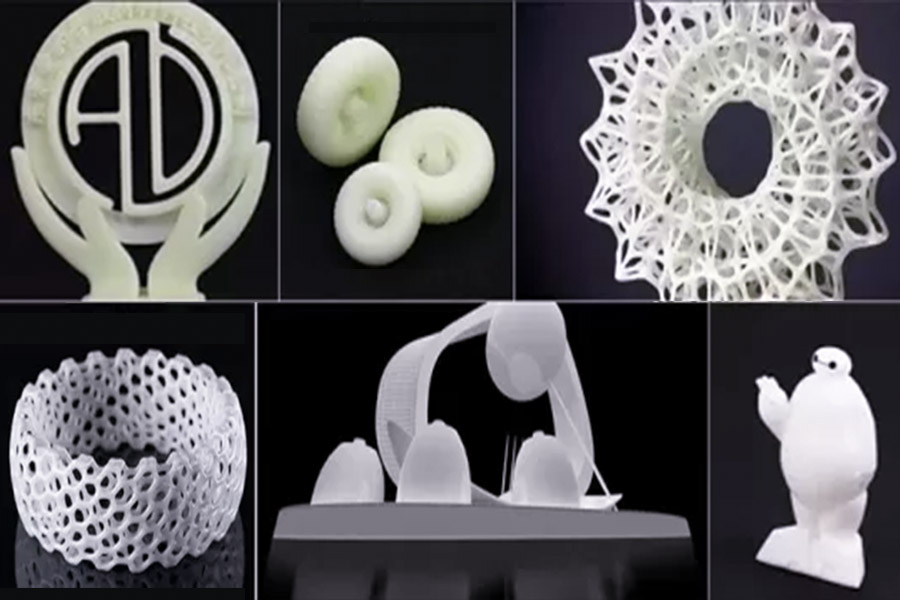

- High precision:Parts printed with SLA resin have extremely high resolution and precision, showing very fine details and textures.

Smooth surface: The cured SLA resin parts have a smooth surface and can achieve good visual effects and tactile feel without subsequent processing. - High mechanical strength:SLA resin has high tensile strength and compressive strength and can withstand certain external forces and pressures.

- Highly customizable:The formula of SLA resin can be adjusted according to specific needs tocustomize printing materialswith different properties (such as hardness, toughness, heat resistance, etc.).

- Good dimensional stability:SLA resin has a low shrinkage rate during the curing process, so the printed parts are dimensionally stable and highly accurate.

- Good processability:SLA resin is easy to process and can be solidified layer by layer by laser or digital projector, making it suitable for printing of various complex shapes.

How Does SLA Resin Compare to FDM and SLS Materials?

Compared with FDM and SLS materials, SLA resin each has unique characteristics and advantages. The following is a detailed comparison of the three:

| Properties/Materials | SLA resin | FDM | SLS |

|---|---|---|---|

| Printing principle | The ultraviolet laser beam irradiates the liquid photosensitive resin, causing it to cure rapidly | Heated nozzles melt the thermoplastic material and extrude it layer by layer | Laser sintering of powder materials, by sintering layer by layer to form a solid model |

| Print accuracy | Extremely high, layer thickness can be as small as 0.025mm | Medium, the layer thickness is usually between 0.1mm and 0.4mm | Moderate, the layer thickness is generally between 0.1mm and 0.2mm |

| Surface | Smooth and delicate, with excellent details | There are obvious stripes and staircase effects | Depending on the powder particle size and sintering process, post-treatment may be required |

| Structural strength | May be brittle, but post-processing can be enhanced | The strength along the perpendicular direction of the forming axis is weak | It usually has good mechanical properties |

| Material costs | It is high, and some special resins are expensive | It is relatively low, and mainly uses ABS, PLA and other wires | Depending on the type of powder chosen, the overall cost may be reduced depending on the scale of production and material utilization |

| Print speed | It is fast, especially suitable for the rapid production of high-precision, small-size models | Medium, suitable for small to medium-scale production and prototyping | Relatively slow because each layer needs to undergo a laser sintering and cooling process |

| Type of material | It is mainly liquid photosensitive resin, and the type is relatively single | There are many types of thermoplastic materials, such as PC, ABS, nylon, etc | Powdered materials, including nylon, polycarbonate, ceramic, metal, and many other powders |

| Supporting structures | Support structures need to be designed and fabricated | Support structures need to be designed and fabricated | There is no need for a support structure, and the powder material is naturally supported |

| Fields of application | High-precision model making, such as jewelry, medical, dental, aerospace, etc | Education, rapid prototyping, manufacturing, and more | Parts that require high strength, complex structures, such as automotive, aerospace, medical implants, etc |

What Are the Applications of SLA Materials?

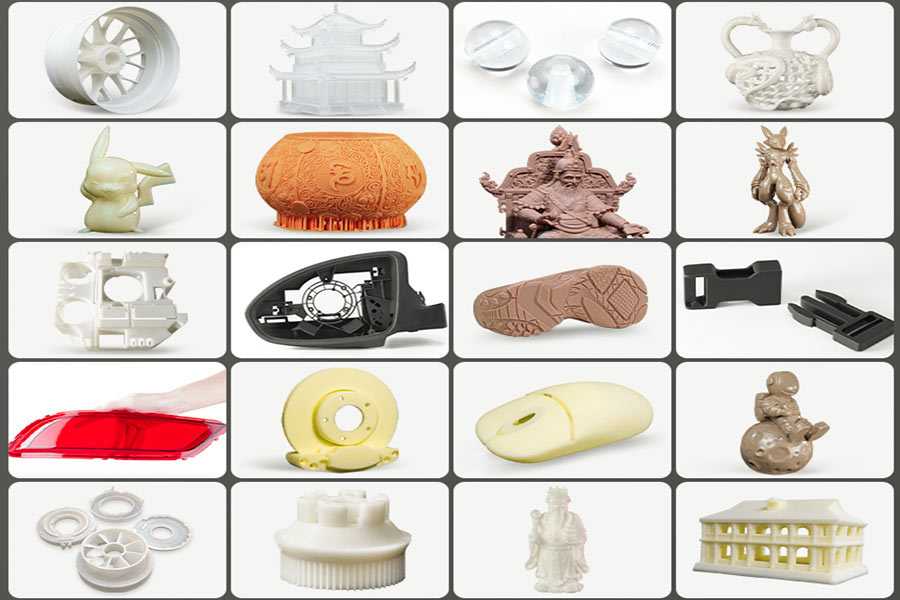

SLA materials(stereolithography materials) have high precision, high surface quality and good detail expression capabilities, so they are widely used in many fields. The following are the main applications of SLA materials:

- In the medical industry,SLA technology is widely used to print high-precision medical devicesand models, such as dental molds, surgical guides, dental restorations, and digital dentures. These models play a crucial role in pre-operative planning, teaching activities, and patient care.

- In the field of industrial design, SLA printing technology is often used to create rapid prototypes, which helps designers quickly verify that their design solutions are feasible. Doing so can help reduce product development time, reduce production costs, and improve the overall quality of the product.

- In terms of artistic creation, artists are able to use SLA technology to create both complex and detailed works of art, such as sculptures and jewelry. Due to the high accuracy of SLA printing technology and the excellent presentation of details, these works of art not only have high aesthetic value, but also have high artistic value.

- In the field of architectural design, SLA technology can be applied to print models of architectural designs, which helps architects to present their design philosophy more deeply and communicate effectively with clients and construction teams. Not only are these models highly accurate and realistic in appearance, but they are also effective in increasing the probability of success of construction projects and increasing customer satisfaction.

- In theautomotive manufacturing industry, SLA technology is widely used,such as for the printing of samples for the manufacture of automotive parts, the interior parts of the engine hood, etc. These applications require the integration and assembly of parts of different sizes, shapes, materials, and constructions to form complex product assembly systems. This will enable automakers to quickly confirm the fit and functional performance of components during product development.

- In the aerospace sector,SLA technology is widely used to produce complex assembly componentsand wind tunnel experimental models. These components play a vital role in the design and production of aerospace vehicles, helping to enhance the overall performance and safety of the aircraft.

How to Choose the Right Material for SLA Printing?

Whenselecting SLA printing materials, multiple factors need to be considered, including material performance, cost, processability, environmental protection, and specific application requirements. Different materials have different advantages, disadvantages and application ranges, so they need to be weighed and selected according to specific circumstances.

Additionally, attention needs to be paid to the storage and handling requirements of the materials. SLA printing materials are usually sensitive to light, temperature and humidity, so they need to be stored and handled properly to avoid material deterioration or impact on print quality.

Summary

As a high-precision and high-efficiency 3D printing technology, stereolithography has broad application prospects in the fields of prototype production, complex structure manufacturing, and customized production. Choosing the rightprinting materialis one of the keys to achieving high-quality printing. By understanding the properties and applicability of different materials, we can better utilize SLA technology to meet various application needs. With the continuous advancement of technology and the emergence of new materials, it is believed that SLA technology will play a more important role in the future.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.What are the main types of materials used in stereolithography?

Stereolithography mainly uses light-curing resin as printing material. These resins undergo a polymerization reaction under the irradiation of ultraviolet light or laser, thereby achieving rapid solidification from liquid to solid state. Specifically, materials commonly used in SLA technology include light-cured acrylic resin, epoxy resin, etc.

2.In addition to light-curing resins, can stereolithography use other types of materials?

Yes, in addition to photocurable resins, stereolithography can also try to use other types of materials, but these materials usually require a certain degree of photosensitivity. For example, some rubber-like materials and resins that can be used as wax substitutes can also be used for SLA printing. However, these materials have a relatively narrow range of applications and may require special post-processing processes.

3.What are the advantages of light-cured resin?

Photocurable resins offer several advantages in stereolithography. First, they cure quickly and can form highly precise three-dimensional structures in a short time. Secondly, light-curing resin has good molding performance and detail expression capabilities, and can print complex and fine structures. In addition, photo-cured resin also has high strength and rigidity and is suitable for manufacturing parts that need to withstand certain loads.

4.What are the development trends in materials for stereolithography in the future?

The future development trend of stereolithography in materials will pay more attention to environmental protection, recyclability and the development and application of bio-based materials. As people's awareness of environmental protection increases and the concept of sustainable development becomes more and more popular, more and more SLA printing materials will be prepared from environmentally friendly raw materials. In addition, in order to meet the performance needs of printing materials in different fields, SLA technology will continue to develop new materials with special functions, such as high temperature resistance, wear resistance, electrical and thermal conductivity and other properties. The emergence of these new materials will further expand the application fields and market prospects of SLA technology.

Resource

Aplication of the stereolithography technique in complex spine surgery