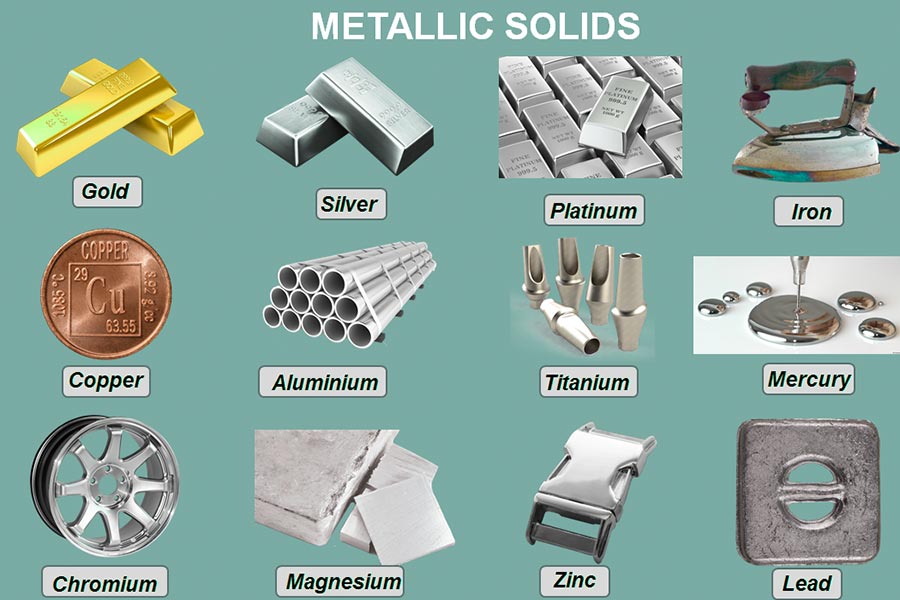

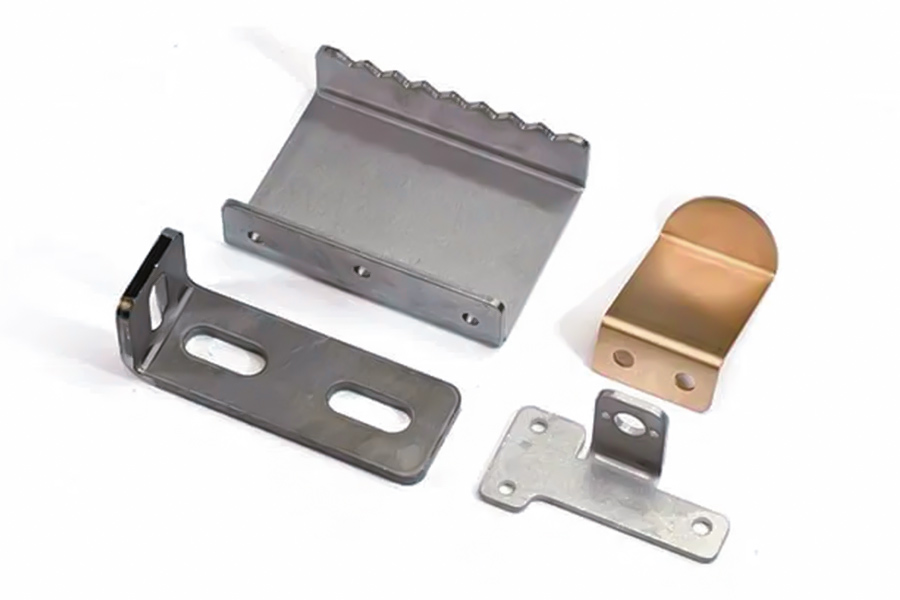

Metal bending is a common manufacturing processused to create a variety of products, from simple brackets and housings to complex parts for industrial machinery and automobiles. The process involves manipulating a metal sheet to form a specific shape by applying pressure to one or more points on the sheet. In this article, we will explore the most commonlyused materials in metal bending.

What Materials Are Used in metal bending?

You cannot bend elastic-plastic materials on a press brake. You may also damage the machine if you try to do this. Special care must be taken when deciding onmaterials for metal bendingduring manufacturing. Let’s take a look at some of the best materials recommended for metal forming and bending.

- Carbon Steel:Carbon steel is one of the most flexible and strongest materials used in sheet metal manufacturing. Since the material is recyclable, it also helps reduce the carbon footprint.

- Aluminum:Aluminum is mainly used in lightweight applications. Special care must be taken when bending aluminum to prevent the material from slumping or cracking at the corners.

- Stainless steel:When the final product needs to be strong and durable and the metal strength is high, stainless steel is the first thing that comes to mind. Stainless steel also requires the use of high-power sheet metal bending machines to form products.

- Titanium:Titanium is a corrosion-resistant and strong material, ideal for metal bending technology. If your product is medical or sports equipment, titanium should be your material of choice.

- Copper:Cost is the most corrosion-resistant material, but also the lowest cost. Copper enables high-precision sheet metal bending. Copper is a proven material used extensively by many metal bending industries for a variety of purposes.

These are the best materials for alltypes of metal bending. Carbon steel is the most commonly used of the above materials. There are many other metals that can be used in the bending process. But be sure to do adequate research before settling on the material.

Metal Bending Compared to Other Fabrication Processes

Compared with other manufacturing processes,metal bending has its own unique characteristicsand advantages, but it also has some limitations. The following table is a comparative analysis of metal bending and other manufacturing processes:

| Process | Best Used For | Process AccuracyLevel | Thickness (mm) | Requires Custom Tools | MOQ | Lead time from CAD to first production |

|---|---|---|---|---|---|---|

| Laser cutting | Small to large parts with every geometry possible | ± 0.10mm | 0.5mm to 20.0mm | No | 1 to 10,000 units | Less than 1 hour |

| CNC sheet bending | Small to large parts with straight anglegeometry, multiple bend possible | ± 0.18mm | 0.5mm to 20.0mm | No | 1 to 10,000 units | Less than 1 hour |

| CNC Punching | Small to large parts with most geometry available, good for parts with multiple holes and embossed | ± 0.12mm | 0.5mm to 4.0mm* | No unless special form required | 1 to 10,000 units | Less than 1 hour |

| Stamping | High volume production with tight tolerances, restricted geometry | ± 0.05 to 0.10mm | 0.5mm to 4.0mm* | Yes from 250 USD to 100,000 USD+ | ≥5,000 units | 25 days to 40 days |

| Shearing | Thin material with simple geometry straight lines and low tolerances requirements | ± 0.50mm | 0.5mm to 4.0mm* | No | 1 to 10,000 units | Less than 1 hour |

What are the tools for metal bending?

Metal bending toolsmainly include the following categories:

1. Bending machine

Thebending machineis one of the most commonly used tools in metal bending. It can be divided into many types according to its type and function:

- Hydraulic bending machine: Powered by a hydraulic system to bend metal sheets. This type of machine has great power and good stability, and is suitable for bending large metal sheets.

- Servo electric bending machine: Using servo motor and control system, it has the characteristics of high precision and high efficiency. Through programming settings, the bending processing of workpieces can be automatically completed, which is suitable for high-precision and high-efficiency production requirements.

- CNC bending machine: Using advanced CNC system, it has a higher degree of automation and processing accuracy. By inputting processing parameters, the CNC bending machine can automatically complete operations such as positioning, clamping, bending and unloading of workpieces, greatly improving production efficiency and processing quality.

2. Special bending mold

Special bending molds are important accessories for bending machines and are used to bend metals of specific shapes and sizes. These molds are usually made of high-strength, high-hardness materials to ensure they are not damaged or deformed during the bending process. Depending on the thickness, material and bending angle of the metal sheet, molds of different shapes and sizes need to be selected.

3. Plate rolling machine

The plate rolling machine is also an important equipment for metal bending. It is mainly used to roll metal sheets into cylindrical, conical or other shapes. The working principle of the plate rolling machine is to apply pressure to the metal plate through rollers, causing it to plastically deform and roll into the required shape. Plate rolling machines have a wide range of applications in the field of metal processing, such as manufacturing pressure vessels, pipes, etc.

4. Pipe bending machine

Pipe bending machines are mainly used for bending metal pipes. It can bend metal pipes into various shapes and angles through different molds and process parameters. Pipe bending machines have the advantages of high processing efficiency and easy operation, and are widely used in pipeline installation and maintenance in petroleum, chemical industry, electric power and other fields.

What Materials Are Used for Specialty Bending Techniques?

The range of metal bending processes is wide and varied, with a variety of techniques used depending on the specific application.

1.V-Bending:

This method is very common and is utilized for mostbending needs. The method uses a “punch” and “V-die” to bend the sheet metal to specified angles. In this process the punch applies force on the sheet metal at the location over the V-die. As a result of the force from the punch an angle is formed in the sheet metal. The V-bending method is relatively efficient because it can be utilized for bending steel plates without having to change their position.

There are three commontypes of V-bending:

※Coining

Coining is a bending process in which the punch and the work piece bottom on the die. This produces a controlled angle, which leads to little spring back. There is more tonnage required on this type of bending than in air bending and bottom bending.

The advantages of coining are that, in order to produce outstanding results, accuracy is essential and that is precisely what the coining method can provide. Along with being accurate, repeating the results is also an easy task when it comes to using this technique. Spring back is also less common when using coining, meaning that the metal is less likely to return to its original state.

※Bottom Bending

Bottom bendingalso uses a punch and V-shaped bottom die, just like air bending. What’s different is that the punch is used to push the metal fully into the die to create a bend. Bottom bending (or bottoming as it’s otherwise known) gets its name because the metal is forced to the bottom of the die. Higher pressures are used, and the metal comes into full contact with the punch and the die.

Because the material is pressed into the bottom of the die, the die that is used will determine the bend angle that’s achieved. With bottom bending, you have to change the die to achieve a different bend angle. This isn’t the case with air bending because the punch can just be pushed to a different depth in the die. Bottom bending results in less springback and creates more accurate angles. The big disadvantage is that each new bend radius requires a different bottom die, which means swapping it manually on the machine. The machinery is also put under more pressure during production.

※Air Bending

Partial bending, or air bending, derives its name from the fact that the working piece does not actually touch the tooling parts entirely. In partial bending, the workpiece rests on 2 points and the punch pushes the bend. Is still usually done with a press brake but there is no actual need for a sided die. Air bending gives much flexibility. Let’s say you have a 90° die and punch. With this method, you can get a result anywhere between 90 and 180 degrees. Though less accurate than bottoming or coining, this kind of simplicity is the beauty of the method. In case the load is released and the material’s springback results in a wrong angle, it is simple to adjust by just applying some more pressure. Of course, this is a result of lessened accuracy compared to bottoming. At the same time, partial bending’s big advantage is that no retooling is necessary for different angle bends.

2. Roll Bending

Thismetal bending techniqueinvolves bending the sheets into curved forms. This technique makes use of roll bending sheet metal criteria, that involve the use of three rollers, a hydraulic pressing system along with a brake. The distance between the three rollers allows the manufacturer to bend the sheets in curves.

3. U-bending

U-bending is exactly similar to the V-bending method. This method makes use of a U-shaped punch along with a U-shaped die. The only difference between V- bending and U-bending is that the resulting sheet is in a U shape instead of a V shape.

4. Rotary bending

The rotary bending method is deployed wherever a bending of greater than a 90-degree angle is required. It can also be considered similar to that of V-bending, but the output in this process is more uniform and aesthetic as the metal sheet bending machine used in this method doesn’t scratch the surface of the sheet.

5. Edge bending

This technique of edge bending sheet metal helps the manufacturer to bend the edges without damaging them. The sheet metal edge bending method is most commonly utilized in those sections of sheet metals that are shorter than the remaining metal part. It helps eliminate the sharpness of the corners and increases the aesthetic appearance of the outcome.

6. Wipe bending

This bending method makes use of a wipe die. The sheet of metal is carefully placed inside the wipe die, and a pressure pad applies pressure on the sheet. Later on, the punch is used to make the desired bend in the sheet.

What are the advantages of metal bending?

As an important metal processing method, metal bending has a range of advantages. The following is a detailed analysis of theadvantages of metal bending:

- Significant cost savings:The metal bending process uses standardized lower and upper dies, which significantly reduces tooling costs compared to forming technologies that require customized molds. Through careful process layout and process optimization, it can effectively reduce raw material consumption, reduce waste output, and then reduce production costs.

- Broad material adaptability:Metal bending technology is suitable for almost all metal materials, especially for sheet metal with excellent ductility such as steel, aluminum, copper and titanium. It is widely used in a variety of industries, such as consumer electronics, packaging, transportation manufacturing, and construction metal components.

- Design flexibility:Metal bending technology enables fast changeovers from flat sheets to three-dimensional parts, which is extremely convenient for design verification and product iteration. Designers are able to quickly adjust and optimize the design while maintaining the stability of the overall production process.

- Efficient production process:Metal bending is easy to operate, and the bending efficiency is not affected by the volume of the workpiece. Using advanced computer-controlled bending machine, it can complete multiple bending operations per minute, which significantly improves production efficiency.

- High precision:The metal bending process is characterized by high precision and a very small error range, usually controlled within about 0.1 mm. This ensures that the quality of the product is stable and meets the standards of high-precision industrial manufacturing.

- Excellent reducibility and reliability:During the metal bending process, the original reducibility and reliability of the metal material can be maintained, and there will be no negative impact on the material properties, thus ensuring the service life of the finished product.

What are the design considerations for metal bending?

Design considerations for metal bendingcover many aspects to ensure a smooth bending process and the quality of the bent part. Here are some key design considerations:

1.Pay attention to rebound

When bending sheet metal, you must bend the material beyond its desired angle. This is because the metal plate has a high ability to bend, allowing it to spring back to its original position. Therefore, this situation must be dealt with by bending the material slightly higher than required.

2.Be sure to use a bending machine

Always use a press brake where applicable as it provides support and ensures cleaner sheet metal bends and a continuous pattern on the bent sheet.

3.Use bend allowance

Bend allowance is a property of metal that determines how easily it can be bent. We recommend that you perform a bend allowance calculation to determine the length of sheet required to make a specific angle and radius bend. Considering bend allowances and bending forces during the manufacturing process will help you achieve cleaner product results. It will also help you create accurately flat manufacturing models.

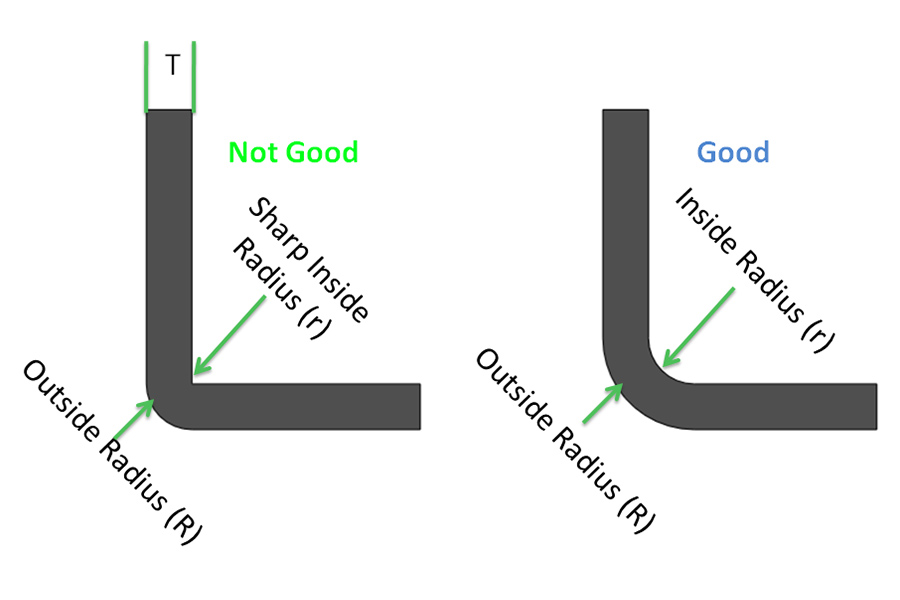

4.Avoid bending into sharp inside corners

When interior corners are sharply curved, internal stresses increase. Even though metals are ductile and malleable, they are prone to cracking. This problem can be greatly reduced if the radius of the bending tool is taken into account. Working back and forth between the bend lines, gradually bend the sheet metal to the desired angle.

Pay attention to the inner bend radius, which must be equal to the thickness of the formed metal sheet. For example, if you are bending a 3 mm thick sheet metal, the inner bend radius should also be 3 mm. The same goes for the bending angle, which must not be greater than the total thickness of the metal plate.

What are the common applications of metal bending?

Metal bending is used in a wide range of applicationsincluding: construction, automotive, transportation, aerospace and infrastructure industries. Sheet metal bending can be used in every industry to create features such as lips, mortises, flanges and dimples. Sometimes, sheet metal bending is used to increase the stiffness of a sheet metal part.

FAQs

1.What is used to bend metal?

There are a variety of tools and equipment used to bend metal, and the choice depends on factors such as the type of metal, thickness, required bend radius and accuracy. Common metal bending tools and equipment include the bending machine, which is one of the most commonly used equipment in metal bending processing. It uses hydraulic or mechanical force to bend metal sheets and is suitable for metals of various thicknesses and materials. Plate rolling machines are mainly used to roll metal sheets into cylinders or cones. It uses three rollers to continuously bend the sheet and is suitable for thicker metal sheets. Profile bending machines are mainly used to bend various metal profiles, such as angle steel, channel steel, round pipes, etc. Hand Bending Tools: For small batches or simple bending tasks, hand bending tools such as pipe benders, wrenches, etc. can be used.

2.What is curved material?

Curved materials refer to materials that are plastically deformed by external forces, thereby changing their shape and size. In metal processing, bending materials usually refer to metal sheets, pipes, profiles, etc. Through bending processing, parts and products of various shapes and angles can be produced.

3.What materials are suitable for bending?

Materials suitable for bending mainly depend on the mechanical properties and processing requirements of the material. Common materials suitable for bending: ① Mild steel: Mild steel has good plasticity and toughness, and is easy to bend but not easy to break. It is one of the most commonly used materials in metal bending. ②Stainless steel: Stainless steel has excellent corrosion resistance and strength, and is suitable for bent parts that require high corrosion resistance and aesthetics. However, the hardness of stainless steel is relatively high, so appropriate bending parameters and molds need to be selected. ③Aluminum alloy: Aluminum alloy has light weight, high strength and good corrosion resistance. It is a commonly used bending material in aerospace, automobile and other fields. Aluminum alloy has good plasticity and is easy to bend, but care needs to be taken to avoid excessive bending that may cause cracks.④Copper alloy: Copper alloy has good electrical conductivity and corrosion resistance, and is suitable for bent parts in the electrical and chemical fields. Copper alloy also has good plasticity and is easy to bend.

4.What parts does bending processing consist of?

The bending process mainly includes ① material preparation: selecting appropriate metal materials and specifications, and performing pre-processing work such as cutting and deburring. ②Mold design: Design a suitable mold according to the shape and size of the bent part. The design of the mold directly affects the accuracy and quality of the bent parts. ③Bending operation: Put the pre-processed metal material into the mold, and perform the bending operation through a bending machine, plate rolling machine or other bending equipment. During the bending process, parameters such as bending angle, bending radius and bending force need to be controlled. ④Inspection and trimming: Inspect the bent parts to check whether their shape, size and surface quality meet the requirements. Trimming and sanding if necessary.⑤Follow-up processing: According to the specific application scenarios and requirements, follow-up processing is performed on the bent parts, such as welding, spraying, electroplating, etc.

Summary

Metal bending is an important process technology, and choosing the right material is the key to ensuring processing quality and efficiency. Materials such as aluminum, copper, brass, carbon steel and stainless steel each have their own advantages and disadvantages in bending processing, and they need to be selected according to specific application scenarios and requirements. At the same time, factors such as the material's physical and chemical properties, processing performance, usage requirements, economy and feasibility also need to be considered to ensure that the quality and performance of the final product meet the design requirements.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.