With the rapid progress of science and technology,3D printing technology is gradually changing our production and lifestylewith its unique charm and wide application prospects. Among them, stereolithography (SLA), as an important technology in the field of 3D printing, stands out among many 3D printing technologies for its high precision, high surface quality and excellent detail performance. So, how exactly does stereolithography work?

Stereolithography is a manufacturing technologyderived from innovative thinking, through the ingenious combination of computer control, ultraviolet laser technology, and liquid photosensitive resin materials, to achieve accurate transformation from digital model to physical object. This is not only a technological breakthrough, but also another leap forward for humanity in the field of manufacturing. In the following, we'll take a closer look at how stereolithography works at its core and how it can play a huge role in manufacturing.

How does stereolithography work?

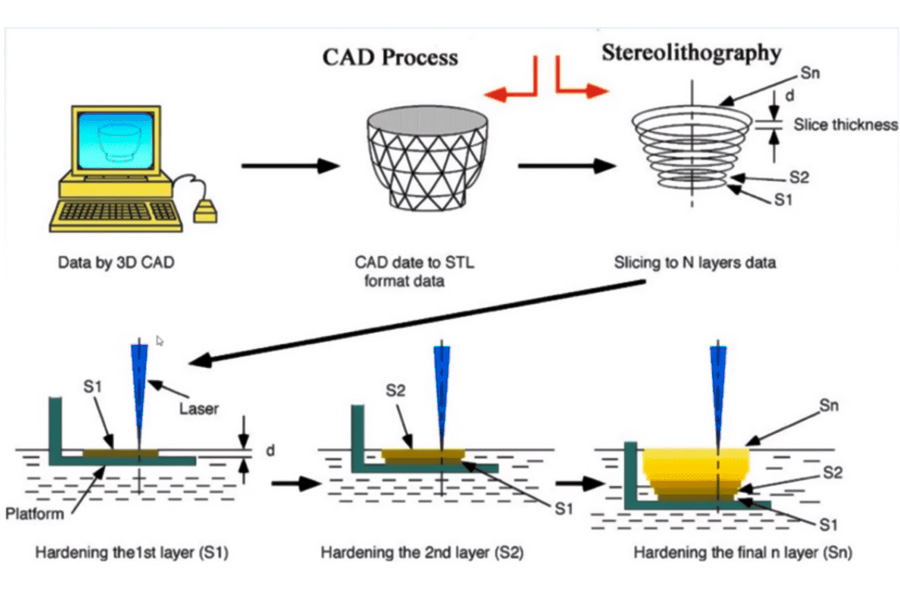

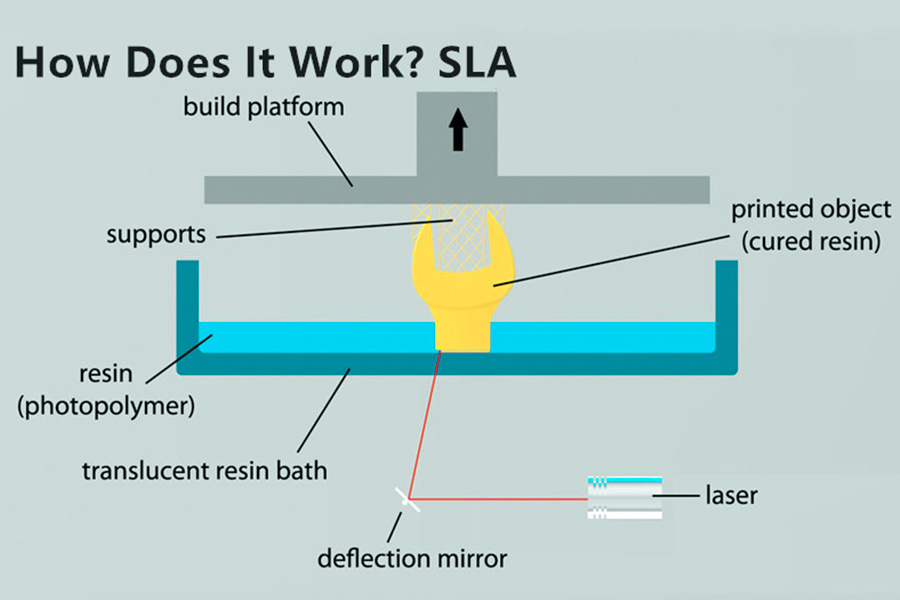

thisTechnical stereolithography workflowSteps include a preparation phase, layer-by-layer curing, platform lowering and resin supply, repeated curing process, and post-processing. First, the liquid photosensitive resin is filled into the resin tank3D printersAnd make sure the stage is below the liquid level. A computer-controlled laser beam then scans the resin surface point by point based on preset 3D model slice data, allowing the resin to solidify in the exposed area. After one layer has cured, the stage is lowered to a preset layer thickness, and the liquid resin in the tank is automatically replenished to the top of the cured layer in preparation for the next layer to cure. Repeat this process until the whole is complete3D modelIt is built layer by layer. Finally, the necessary cleaning and post-curing are carried out to obtain the complete 3D printed product.

What are the steps of the stereolithography process?

Thestereolithography processmainly includes the following steps:

| process | description |

| Design the model | First, a 3D solid model is designed using CAD software. |

| Slicing processing | Use a discrete program to slice the model, i.e., cut the 3D model into a series of 2D sections. At the same time, the scanning path is designed to precisely control the movement of the laser scanner. |

| Laser scanning curing | The laser beam passes through a scanner controlled by a CNC device and illuminates the surface of the liquid photopolymer according to the designed scanning path. Under ultraviolet irradiation, a layer in a specific area of the resin surface undergoes a polymerization reaction and solidifies from a liquid to a solid state, forming a cross-section of the part. |

| Lift table movement and resin covering | When machining one layer, the lift table moves vertically to the height of the first layer (typically between 25 and 100 microns). Then, another layer of liquid resin is covered on top of the cured layer in preparation for scanning and curing the next layer. |

| Layer by layer | Repeat the above steps for laser scanning curing, lift table movement, and resin overlay until all layers have cured. In this way, the three-dimensional workpiece prototype is formed layer by layer. |

| Post-processing | Once the prototype is removed from the resin, it is finally cured (usually with UV light for secondary curing). Then, polish, plate, paint, or color as needed to get a product that meets the requirements. |

What materials are used in stereolithography?

The mainmaterials used in stereolithographyare liquid photopolymers, the most common of which include light-curing acrylics and epoxies. These resins cure upon exposure to ultraviolet light, forming a solid model. Specifically, the applications and characteristics of these materials are as follows:

- Light-curable acrylics:This resin has good clarity and curing properties, so it is often used to make transparent or translucent models. However, curing the model may require post-processing, such aspolishing and coating, to achieve the desired clarity.

- Epoxy resin:Epoxy resins have high strength and good chemical resistance, making them suitable for manufacturing models that need to withstand certain loads or are exposed to harsh environments.

In addition, depending on the specific application needs, other types of liquid photopolymers can be used, such as rubber-like materials (used to replicate rubber products) and resins that can be used as wax substitutes. The choice of these materials depends on factors such as the desired physical properties, chemical properties, and cost.

How does SLA compare to other 3D printing technologies?

SLA (stereolithography technology) is very different from other3D printing technologiesin many ways. The following is a comparative analysis of the three mainstream3D printing technologies of SLA, FDM, SLS, and DLP:

SLA vs. FDM

- Accuracy and surface quality:SLA technology provides extreme manufacturing precision and excellent surface quality by using laser-precision to cure resins, often superior to FDM technology.FDM technologyis limited by the size of the nozzle head. Prints have large details and layer thicknesses, and surface delamination is noticeable.

- Cost & Materials:The cost of equipment and materials for SLA technology is typically higher than for FDM technology. SLA requires the use of specific photosensitive resins, whereas FDM uses thermoplastic filaments such as ABS, PLA, etc., with a comparatively low material cost.

- Printing speed:FDM technology is faster when printing large objects because it directly constructs objects by depositing molten material. SLA technology may be more advantageous on small or complex objects, but the overall print speed may be slower due to the laser scanning path and time.

SLA vs. SLS

- Printing Principle:SLA is a resin-based printing technology that useslaser curingof liquid resin to construct three-dimensional solids. SLS is a powder-based printing technology that uses a laser to sinter powdered materials, such as nylon, to form solid parts.

- Accuracy and surface quality:SLA technology generally provides higher accuracy and surface quality thanSLS technology. SLS parts may have lower accuracy and surface roughness, but have higher mechanical properties for applications that require a certain amount of load.

- Apply:SLA technologyis better suited for fields such as prototyping and artwork printing that require high precision and smooth surfaces. SLS technology is better suited for printing functional parts such as tools, molds, and durable parts.

SLA vs. DLP

- Light source and curing method:SLA uses a laser as a spot light source to cure the resin layer by layer by controlling the position and intensity of the beam. DLP uses a single light source, such as a DLP projector, to project a model pattern onto the resin and cures the resin layer by layer by controlling the projection pattern.

- Print Speed & Accuracy:DLP technologyis typically faster than SLA technology because it cures the entire cross-section of the layer in one go. However, in terms of print accuracy, the SLA may be slightly better because it uses a laser for precise curing. However, DLP's printing accuracy is high enough to be used in most applications.

- Cost & Materials:DLP technology may use relatively inexpensive resin materials and may be more efficient due to the way the overall light source cures. SLA technology may require the use of more expensive photopolymers, and laser maintenance costs may also be higher.

What are the key components of an SLA printer?

Thekey components of SLA printersmainly include the following:

- Laser:It is the core component of SLA printers and is responsible for generating the laser beam, which is key to achieving the curing of photopolymers.

- Galvanometer system:The system controls the scanning direction of the laser beam to ensure that the laser beam scans the surface of the liquid photosensitive resin within a predetermined path.

- Liquid supply system:Including resin containers, circulation systems and other parts, responsible for the supply and circulation of liquid photosensitive resin materials to ensure the continuous supply of resin in the printing process.

- Locomotor system:It includes movement mechanisms in the X, Y, and Z directions, as well as frameworks to support them. The X and Y motion mechanism is used to control the position of the laser beam on the liquid surface, and the Z direction motion mechanism is used to control the lifting of the printing platform to achieve layer-by-layer printing.

- Optical system:Used in conjunction with the motion system, the position of the print head and the focus of the laser beam are controlled, ensuring that the laser beam can be accurately projected onto the surface of the liquid resin and form a cured layer.

What are the applications of stereolithography technology?

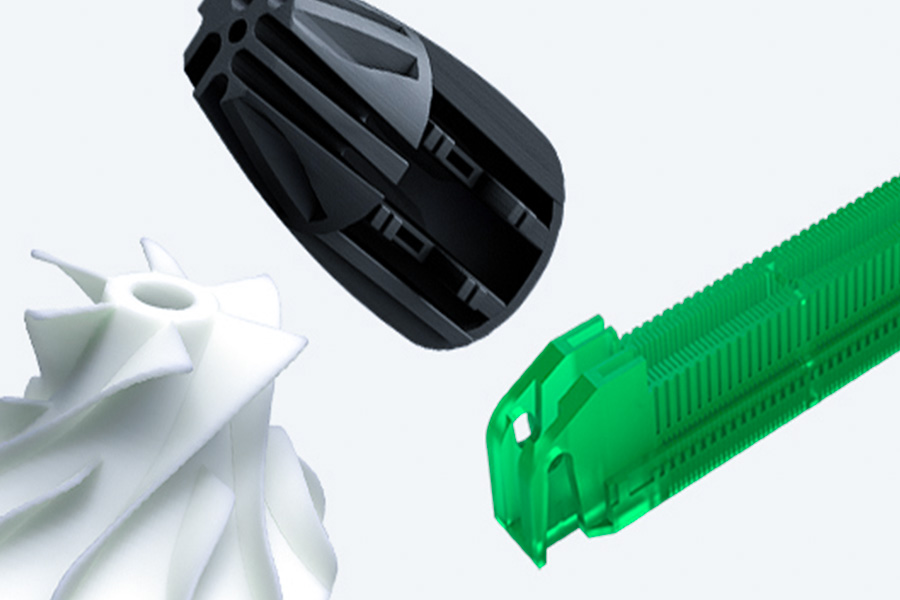

Theapplication range of stereolithography technology is very wide, mainly including the following aspects:

- Manufacturing:In manufacturing,stereolithography is used to make molds, models, and appliances.Its high precision and ability to represent details make the manufactured products very high.

- Medical Field:In the medical field,stereolithography is widely used to manufacture human organ models, bone models, artificial blood vessels, etc. It can help doctors better understand the anatomy of patients and provide strong support for surgical planning and teaching. In addition, stereolithography combined with slice X-ray photography (CT) can easily replicate human organ models, providing a new means for medical research and treatment.

- Architecture & Engineering:In the field of architecture and engineering design, stereolithography can be used to manufacture architectural models and fluid experimental models to help designers better understand and optimize design options.

- Research Interests:Stereolithography is also widely used in scientific research, such as preparing accurate molecular models for chemical and biological research. In addition, it can be used to reproduce archaeological artifacts, providing important support for archaeological research.

- Arts & Cultural Innovation:In the field of art and cultural creativity, stereolithography can be used to create artworks and models with complex shapes, providing artists with more creative inspiration and possibilities.

What is the development trend of stereolithography technology?

As technology continues to advance, so does SLA technology:

- Increase Print Speed:By improving the laser scanning method, using video projectors and other technologies, it is possible to increase the printing speed of SLA technology.

- Cost Reduction:With the expansion of production scale and the maturity of technology, the cost of SLA printers has gradually decreased, making this technology more acceptable to more businesses and individuals.

- Extended application areas:With the deepening of SLA technology research, its application in aerospace, automobile manufacturing and other fields will continue to expand.

Summary

Stereolithography is based on the principle of photopolymerization, using UV-sensitive resins to generate 3D models, enabling rapid prototyping and high-precision component production. Stereolithography has an important position in the field of3D printingdue to its high precision, material diversity, and layer-by-layer structure. With the continuous advancement of technology and the expansion of application fields, SLA technology will continue to bring more innovation and change to the field of manufacturing and prototyping.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest 24-hour delivery. chooseLS TechnologyIt means choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

Frequently Asked Questions

1. What is stereolithography and how does it work?

Stereolithography is an additive manufacturing technology that uses liquid photosensitive resins as materials and uses ultraviolet lasers to cure these resins layer by layer to construct three-dimensional objects. In a specific job, a laser beam is scanned point by point on a liquid resin surface under computer control based on preset 3D model data. The laser-irradiated resin undergoes a photopolymerization reaction and rapidly transforms from a liquid state to a solid state. This process is carried out layer by layer until the entire object is completely printed.

2. How does an SLA printer work?

SLA printers work on the same principle as stereolithography technology. It uses a UV laser beam to irradiate a liquid photosensitive resin and cause it to solidify layer by layer at a fixed position to form an object. Inside the printer there is a liftable stage that moves through the resin tank to ensure that each layer cures and the next layer cures accurately. The entire printing process is precisely controlled by a computer to ensure that the printed object is consistent with the preset 3D model.

3. What is the principle of the stereolithography process?

The principle of the stereolithography process is based on the photopolymerization of liquid photopolymers. When a liquid photosensitive resin is irradiated with ultraviolet light, the photosensitive molecules in the resin undergo a chemical reaction to form a polymer and solidify. This curing response is fast and precise, allowing SLA printers to build 3D objects layer by layer. At the same time, due to the focusing characteristics of UV light, SLA printers can achieve high-precision printing results.

4. How does the SLA compare to FDM printing?

There are many differences between SLA and FDM printing: Accuracy and surface quality: SLA printing can provide higher accuracy and a more delicate surface finish, making it suitable for printing complex and delicate models. While FDM printing can also print three-dimensional objects, the surface can be layered and relatively inaccurate. Print speed: This depends on the specific printer model and the size and complexity of the object being printed. In general, FDM printers can be faster when printing large objects because it directly builds objects by depositing molten material. SLA printers can have an advantage when dealing with small or complex objects, but the overall print speed can vary depending on the laser scanning path and time. Cost and materials: SLA printers are typically more costly and require more materials and equipment. At the same time, the cost of liquid photopolymer resin materials used in SLAs is comparatively high. FDM printers, on the other hand, are more commonly used to manufacture tools and large parts due to their stability and low cost. The thermoplastic filament material they use is relatively low-cost.

Resource

Application of stereolithography in complex spine surgery

Application of stereolithography rapid tools in the manufacture of metal injection molded parts