In the ever-evolving world of industrial innovation, **surface finishing techniques** play a pivotal role in enhancing both aesthetics and functional attributes of products. Particularly in industries where metal components reign supreme, these techniques are indispensable. Among these, the LS Hardware Tech Co., Ltd proudly introduces its latest marvel, the Multi-Slot Fastening Nut—a product that embodies excellence and precision in engineering.

Surface finishing techniques are not just about making metals look appealing; they also provide essential benefits like corrosion resistance and enhanced wear durability. Metal surface finishing is an art that combines chemistry, physics, and engineering to create surfaces that are not only beautiful but are also built to last. For LS Hardware Tech Co., Ltd, expanding these capabilities means advancing the very fabric of industries like automotive, medical devices, and aerospace.

LS Hardware Tech Co., Ltd, a well-established name in the hardware industry, was founded by Mr. Nick Zhang and his team of seasoned engineers. With over two decades of dedication and excellence, Nick has set a benchmark, aiding over 5,000 global clients with premium solutions. The company prides itself on its cutting-edge facility—equipped with more than 100 state-of-the-art machining centers, emphasizing high production efficiency and superior output standards.

The Need for High-Quality Surface Finishing

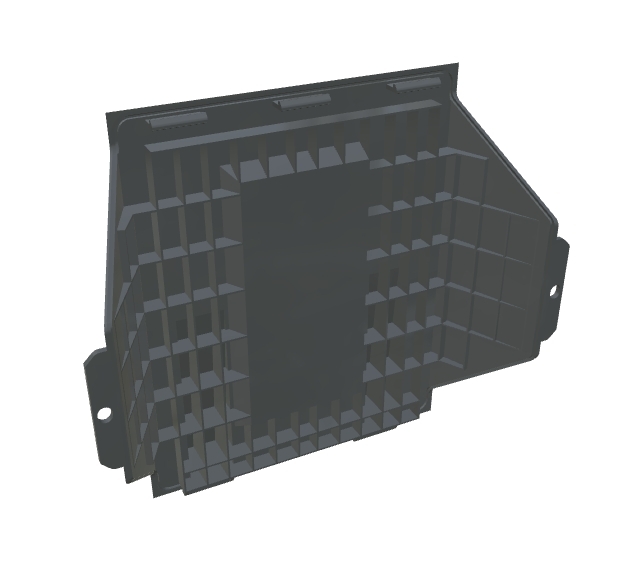

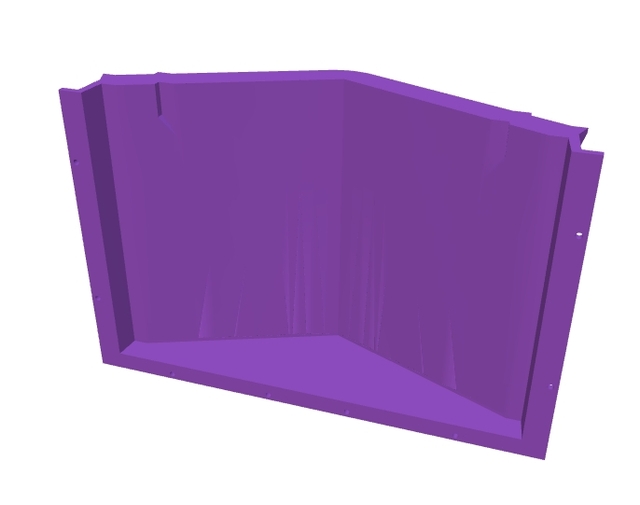

Understanding the importance of surface finishing processes is crucial for those in the manufacturing and transportation sectors. Surface finishing materials, which include techniques like electropolishing surface finishing and polishing surface finishing, give metal components essential properties that enhance their performance and lifespan. Electropolishing, for instance, is a precise method designed to smooth and polish surfaces, improving corrosion resistance and aesthetic appeal—a crucial attribute for LS's new Multi-Slot Fastening Nut.

Polishing surface finishing further enhances the nut's design, making it an attractive and highly functional component for integrating seamlessly into various machinery, from automotive to high-tech industrial equipment. These capabilities are imperative to LS's customers who require high-precision parts that not only fit perfectly but also maintain their integrity under stress and harsh environments.

The Industrial Surface Finishing Landscape

Industrial surface finishing is a cornerstone of LS Hardware Tech Co., Ltd's operations. The LS team employs advanced techniques to ensure their products meet the highest standards of wear resistance, longevity, and precision—all attributes vital in competitive settings. This dedication to quality is mirrored in their mission to remain at the forefront of technology, perpetually enhancing their processes and capabilities.

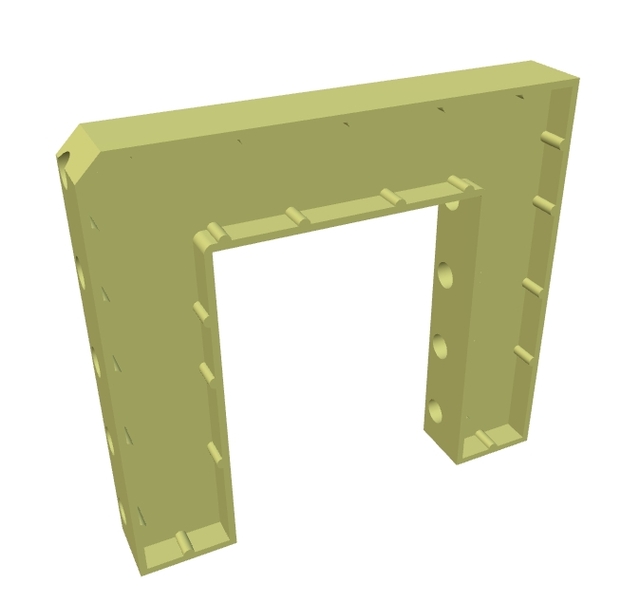

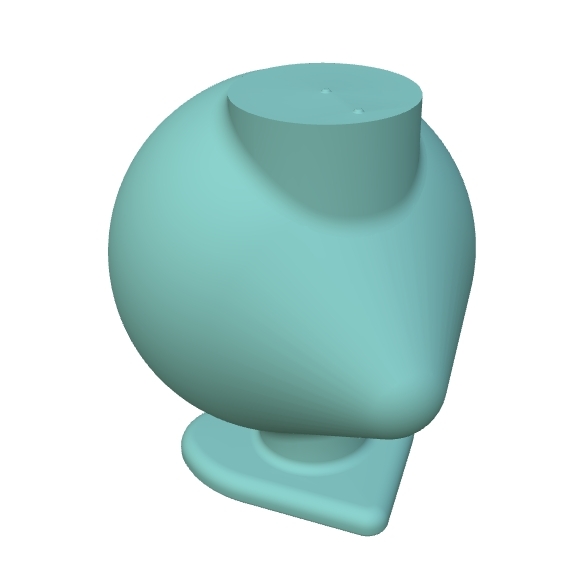

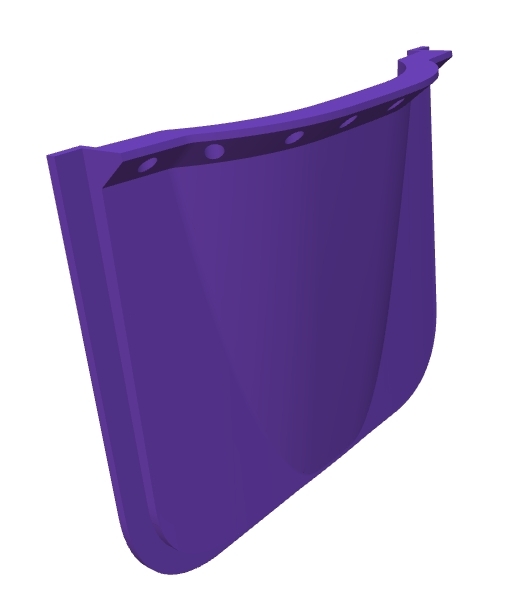

The Multi-Slot Fastening Nut is a prime example of this commitment, reflecting a blend of innovation and reliability. Its robust, sleek construction and the seamless integration offered by its cylindrical design are ideal for applications that demand not only functionality but also aesthetic sophistication.

The Unique Edge Offered

Nick Zhang and LS Hardware Tech Co., Ltd exemplify a commitment to continuous improvement and innovation, with their operations stretching across more than 150 countries. As an ISO 9001:2015 certified company, LS distinguishes itself by offering exceptional surface finishing services that are essential across a diverse array of industries. Clients choose LS because of the company's unwavering dedication to quality and efficiency, making LS a trusted partner in precision part production, prototype creation, and mass manufacturing.

Whether the demand lies in automotive assemblies or intricate aerospace components, the Multi-Slot Fastening Nut meets and exceeds expectations with its durability and versatile application options. This is achieved by incorporating advanced surface finishing techniques that ensure these components not only function seamlessly but also fit the visual and operational ethos of cutting-edge machinery.

In conclusion, surface finishing techniques are much more than a process in the realm of metalwork; they signify a commitment to excellence, longevity, and style. With their innovative Multi-Slot Fastening Nut, LS Hardware Tech Co., Ltd bridges the gap between elegance and practicality, reflecting their deep-rooted mission to empower clients with innovative manufacturing solutions.