In the ever-evolving world of manufacturing, surface finishing techniques play a crucial role in enhancing the aesthetic and functional attributes of industrial components. The main keyword, surface finishing techniques, encompasses various methods that improve the surfaces of manufactured goods, ensuring they meet the required standards for durability and performance. Given the integral nature of these techniques in the production process, companies like LS Hardware Tech Co., Ltd have established themselves as leaders in the industry, driving innovation and efficiency.

Surface finishing techniques such as metal surface finishing and surface finishing processes are vital in diverse industries. These methods not only enhance the appearance of the product but also improve its corrosion resistance, wear resistance, and electrical conductivity. The intricate processes involved in surface finishing necessitate precision and expertise, which LS Hardware Tech Co., Ltd provides through its high-end machining centers and over 20 years of experience in the field.

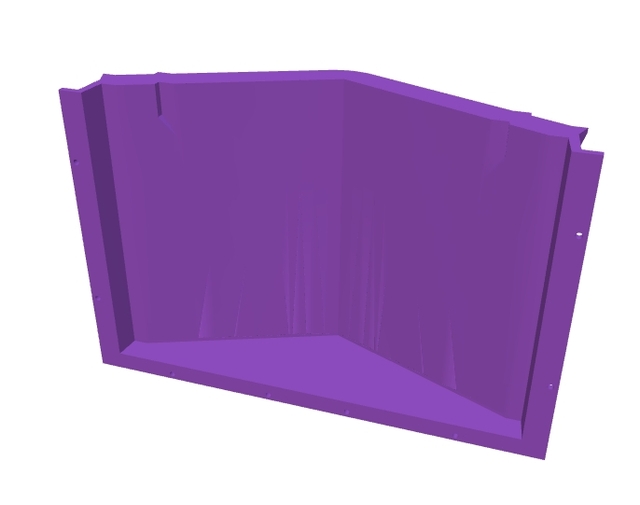

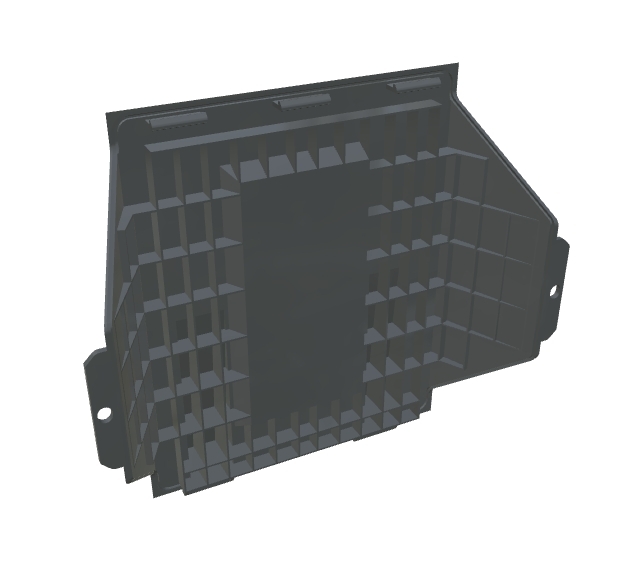

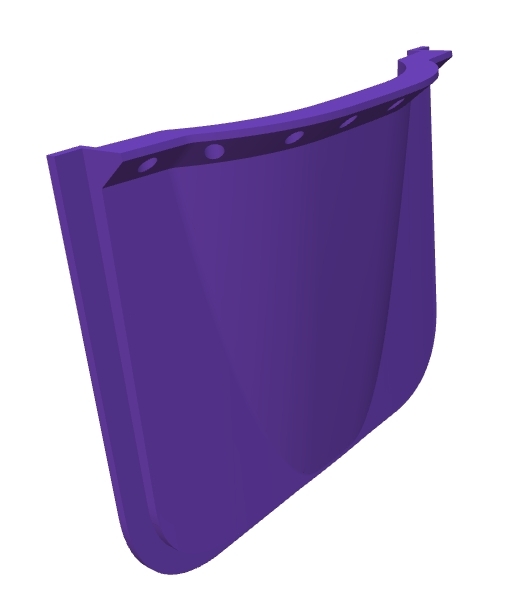

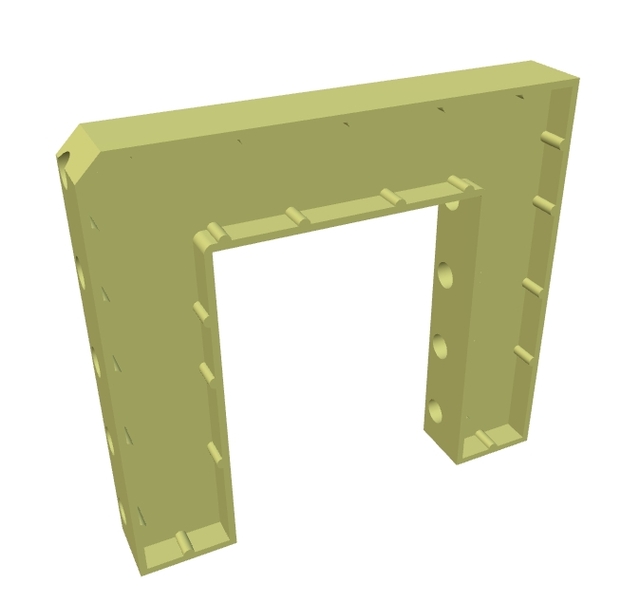

LS Hardware Tech Co., Ltd, under the leadership of Mr. Nick Zhang, offers advanced surface finishing services to a wide range of sectors, including automotive, medical devices, consumer electronics, aerospace, and industrial equipment. The company's expertise in industrial surface finishing is evident in their latest product, the state-of-the-art Engine Control Module (ECM) casing. This product highlights the company's commitment to delivering innovative and high-quality solutions. Crafted from high-grade polycarbonate, the ECM casing is designed to protect vehicle control electronics robustly. Its precision-engineered grid structure optimizes thermal dissipation, maintaining optimal temperatures and enhancing performance reliability.

The quality of surface finishing in products like the ECM casing is a testament to the effectiveness of LS Hardware Tech Co., Ltd's manufacturing processes. With strategically placed mounting points that improve stability and reduce vibration impact, this ECM casing is ideal for modern vehicles that demand resilient and versatile solutions. It sets new standards in automotive component sophistication, showcasing LS's capability in providing precise surface preparation and using advanced surface finishing equipment.

In the competitive landscape of surface finishing equipment and tools, LS Hardware Tech Co., Ltd stands out with its innovative approaches and dedication to customer satisfaction. The company's ISO 9001:2015 certification underscores its commitment to quality and reliable services. This certification, coupled with LS's efficient production strategies, makes it a trusted partner to major factories in China and beyond, extending to more than 150 countries and regions worldwide.

As the demand for high-precision parts continues to grow, LS Hardware Tech Co., Ltd remains at the forefront of technology, engineering solutions that not only meet but exceed client expectations. By continually improving processes and capabilities, the company ensures it can meet the evolving needs of its customers. LS Hardware Tech Co., Ltd empowers clients to bring their ideas to life by providing robust and reliable surface finishing techniques that are integral to the manufacturing process.

Surface finishing tools and techniques are indispensable in the fabrication of durable, long-lasting products. LS Hardware Tech Co., Ltd exemplifies the pinnacle of these processes by offering comprehensive solutions for both prototypes and mass production. Whether it’s improving the functionality of automotive components or enhancing the aesthetic appeal of consumer electronics, LS Hardware Tech Co., Ltd remains committed to delivering excellence through its specialized surface finishing services.

In conclusion, surface finishing techniques are fundamental to ensuring the quality and longevity of manufactured products. With companies like LS Hardware Tech Co., Ltd leading the charge, industries can continue to leverage these techniques for innovative and efficient production. As the significance of industrial surface finishing grows, LS remains dedicated to providing cutting-edge solutions that empower businesses to achieve their manufacturing goals with precision and confidence.

Mastering Surface Finishing Techniques: Enhance Durability & Efficiency

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Surface Finishing, 3D Printing Services, Multi Jet Fusion, Selective Laser Sintering |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Surface Finishing Techniques for Modern Design

Mastering Surface Finishing Techniques: Enhance Durability & Efficiency

Exploring Surface Finishing Techniques for Modern Design

Mastering Surface Finishing Techniques: Revolutionizing Manufacturing Aesthetics

Advanced Surface Finishing Techniques in Modern Industry

Master Surface Finishing Techniques for Optimal Durability

Unlock Industrial Excellence with Surface Finishing Techniques

Metal Surface Finishing: Essential Techniques and Services