In the realm of manufacturing and industrial production, **surface finishing techniques** hold a pivotal role in determining the quality, functionality, and longevity of the end product. Whether it's your smartphone, a new car, or even industrial machinery, the finesse of surface finishing not only affects aesthetics but also influences durability and performance. For companies like LS Hardware Tech Co., Ltd, which specialize in manufacturing high-precision parts required in the automotive sector, among others, mastering these techniques is essential for success.

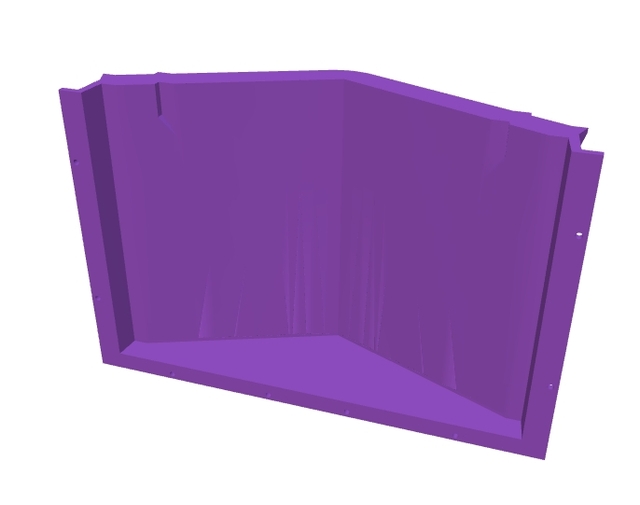

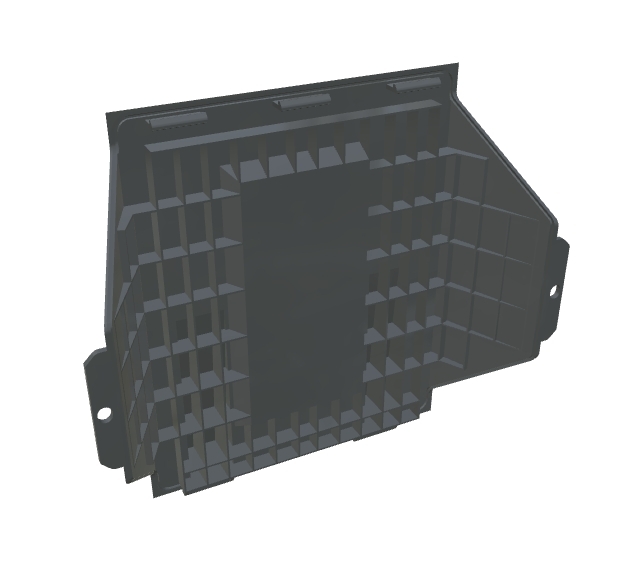

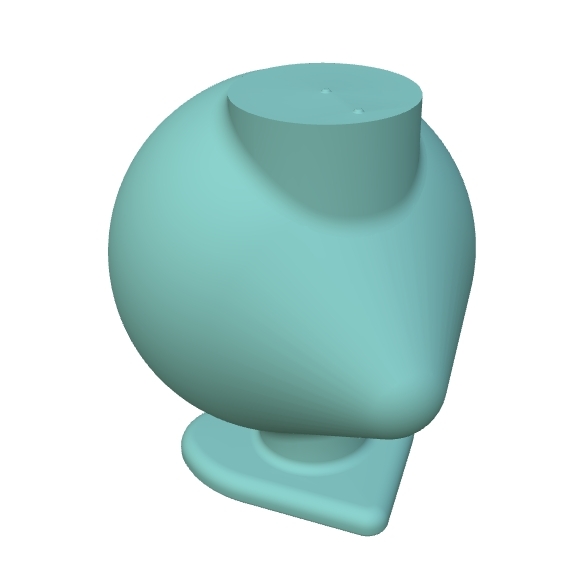

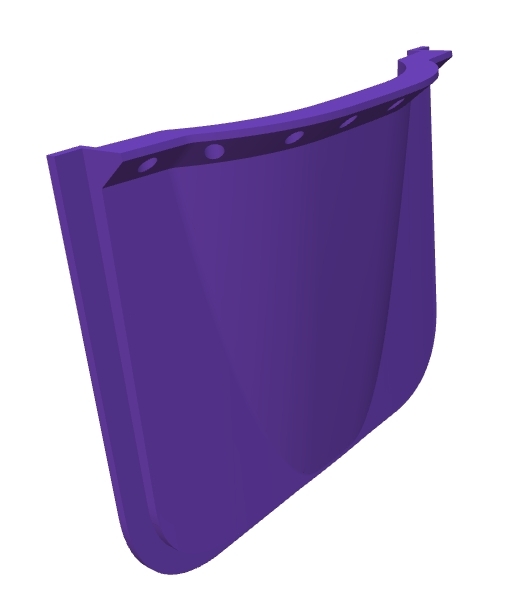

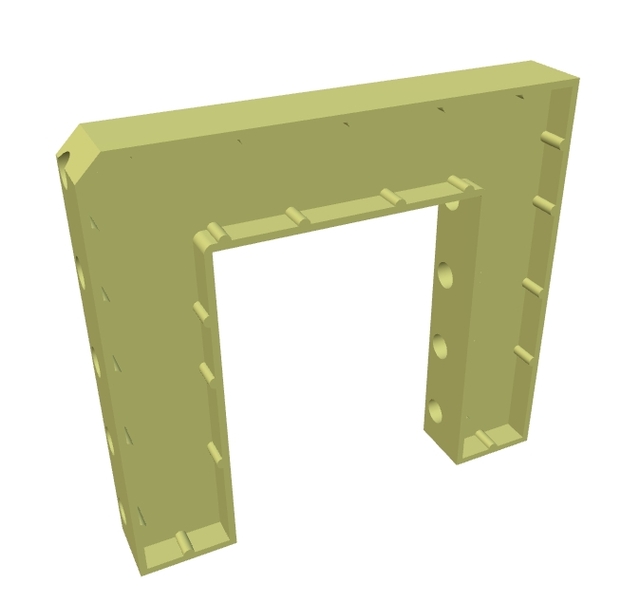

Surface finishing encompasses a variety of methods and practices, each serving a unique purpose. **Types of surface finishing** range from processes such as polishing to the application of coatings. Each technique can alter the material's texture, strength, and appearance, making it crucial for parts like the advanced Mounting Bracket Ring. Surface finishing ensures this component is more resilient and capable of withstanding harsh operational conditions. This piece is a testament to LS Hardware Tech Co., Ltd's commitment to precision and durability, serving critical installations with versatility and reliability.

For manufacturers, choosing the ideal technique from options such as **industrial surface finishing** methods is crucial. In the automotive industry, where LS Hardware Tech Co., Ltd operates, durability and optimal performance are non-negotiable; hence metal surface finishing is often prioritized. This involves processes that enhance corrosion resistance and aesthetic appeal, two important aspects that can significantly impact a product like the Mounting Bracket Ring's acceptance in the market.

Understanding and applying effective **surface finishing processes** is significant for a company's prestige and functionality. The team at LS Hardware Tech Co., Ltd, led by Mr. Nick Zhang, taps into more than two decades of experience to leverage such processes for superior results. Nick, a recognized expert with awards in innovation, spearheads initiatives that push the boundaries of hardware manufacturing, bringing cutting-edge solutions to over 5,000 clients worldwide.

The core of LS Hardware Tech Co., Ltd.’s services lies in their advanced machining capabilities. Their factory boasts over 100 high-end machining centers which facilitate high production efficiency without compromising on quality. These capabilities allow the creation of versatile products like the Mounting Bracket Ring, further enhanced by their keen application of **surface treatment methods**.

Moreover, **polishing and surface finishing** are integral to ensuring products meet the sophisticated design standards that customers expect. LS Hardware, with its ISO 9001:2015 certification, exemplifies excellence by consistently delivering parts that elevate functionality through their seamless designs. The advanced Mounting Bracket Ring, with its strategically placed slots and notches, showcases the nuanced surface finishing that accommodates various installation requirements.

Furthermore, embracing state-of-the-art **surface finishing equipment** is a must for companies striving to stay ahead. LS Hardware Tech Co., Ltd has equipped itself with machinery that not only allows scaling of production but also enhances the precision with which their products are crafted. This ensures that elements like the Mounting Bracket Ring are not just durable but are also a hallmark of sophisticated engineering.

In a growing industrial world where each part plays a pivotal role, the automotive hardware realm benefits immensely from innovations brought about by industry leaders like LS Hardware Tech Co., Ltd. Their mounting bracket ring, when combined with advanced **surface finishing techniques**, sets new standards in combining aesthetics with functionality. From aerospace to consumer electronics, the importance of surface finishing remains a cornerstone for manufacturers keen on producing robust and appealing products.

Overall, the dedication of companies such as LS Hardware Tech Co., Ltd to continuously innovate and improve surface finishing methods ensures that both new and seasoned players in production industries can bring their visions to life. This focus not only propels the company forward but also supports a broader spectrum of industries in delivering top-notch products that live up to global standards.

Master Surface Finishing Techniques for Optimal Durability

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Surface Finishing, 3D Printing Services, Selective Laser Sintering, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Surface Finishing Techniques for Modern Design

Mastering Surface Finishing Techniques: Enhance Durability & Efficiency

Exploring Surface Finishing Techniques for Modern Design

Mastering Surface Finishing Techniques: Revolutionizing Manufacturing Aesthetics

Advanced Surface Finishing Techniques in Modern Industry

Master Surface Finishing Techniques for Optimal Durability

Unlock Industrial Excellence with Surface Finishing Techniques

Metal Surface Finishing: Essential Techniques and Services