In the dynamic world of manufacturing, surface finishing techniques play an integral role in enhancing the quality and aesthetics of finished products. Surface finishing is more than just an aesthetic add-on; it's a critical process that can influence the functionality, durability, and lifespan of components manufactured for various industries. Understanding metal surface finishing and its associated processes, materials, and equipment provides insight into how such techniques have revolutionized modern manufacturing.

Surface finishing processes refer to a variety of procedures used to alter the surface of a manufactured item to achieve a desired property. Whether the goal is to improve appearance, increase durability, or enhance corrosion resistance, the right type of surface finishing can make all the difference. Types of surface finishing include sanding, polishing, electroplating, anodizing, and powder coating among others. Each of these methods offers distinct advantages tailored for specific applications and industries.

A prime example of innovative application of surface finishing techniques is demonstrated by LS Hardware Tech Co., Ltd. This esteemed company has carved a niche in providing high-precision parts and surfaces, underpinning its stellar reputation in the surface finishing industry. Founded by Mr. Nick Zhang and a cadre of proficient engineers, the company thrives on over 20 years of extensive experience in manufacturing hardware and plastic parts. As an industry leader, LS Hardware Tech Co., Ltd. has equipped its operations with over 100 high-end machining centers, assuring high production efficiency and top-notch quality.

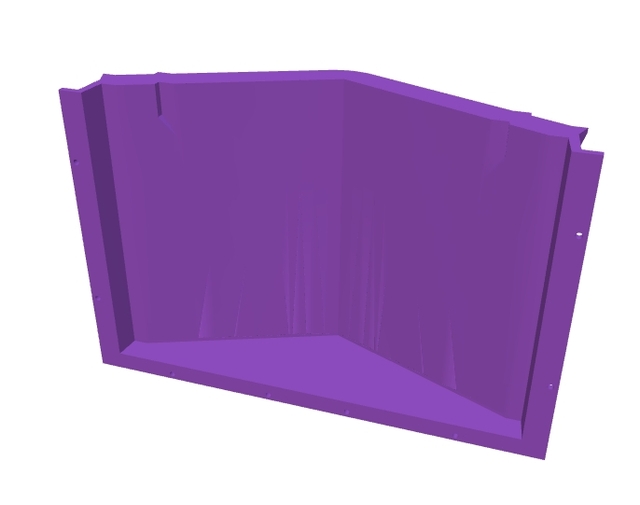

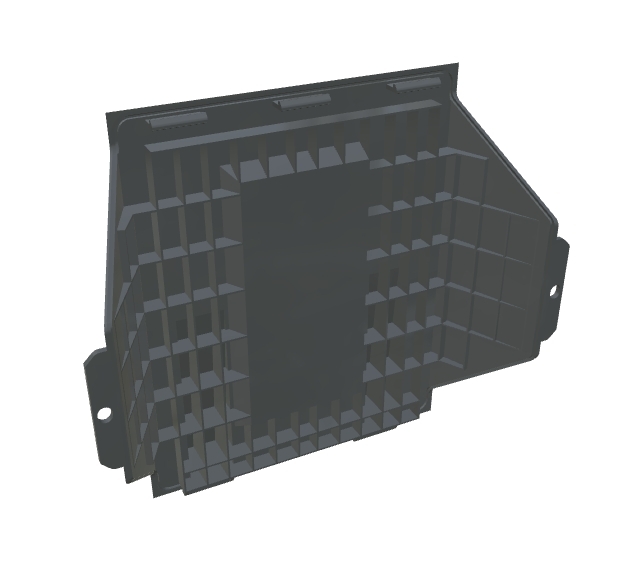

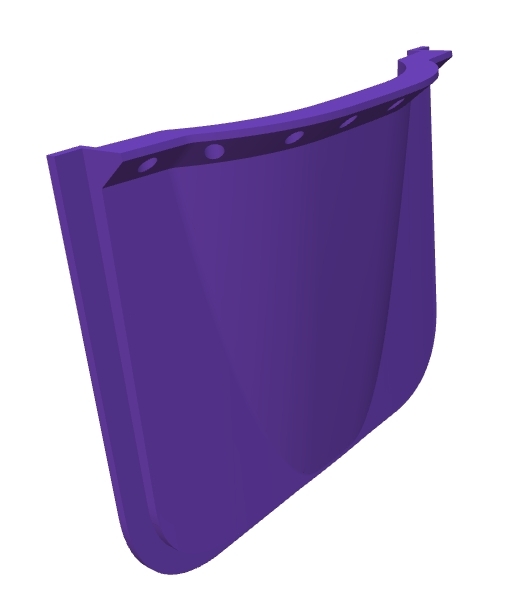

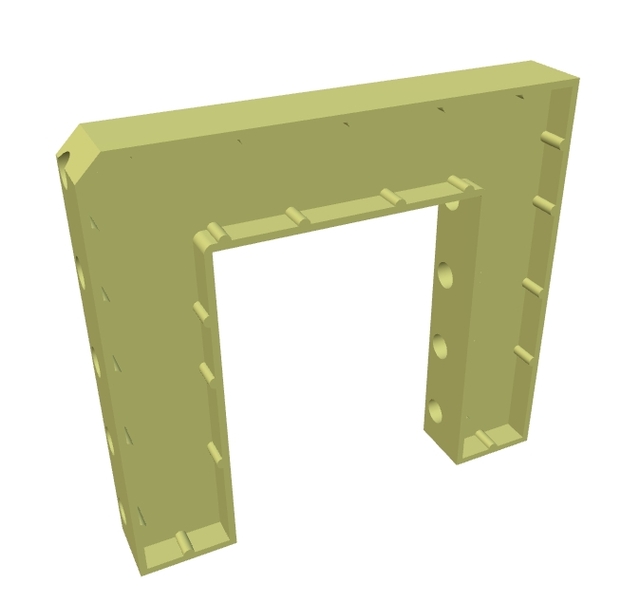

LS Hardware Tech is renowned for its ability to provide custom solutions that meet clients' unique needs across industries such as automotive, aerospace, consumer electronics, and medical devices. For instance, their incorporation of advanced techniques is evident in the development of the Purple Splash Guard, a testament to their innovative prowess. Crafted with high-quality, robust materials, this splash guard is designed not only for its vibrant aesthetic appeal but also to outperform traditional counterparts, epitomizing the perfect marriage of style and function.

The Purple Splash Guard exemplifies the sort of product that can be enhanced through meticulous surface finishing techniques. With strategic hole placements and contoured edges, it ensures a seamless fit and optimal functionality, truly epitomizing LS Hardware’s commitment to delivering practical yet eye-catching solutions. Such comprehensive utilization of surface finishing techniques demonstrates how a dynamic, fashion-forward approach can redefine protective gear in the automotive industry.

The surface finishing materials employed in creating such groundbreaking products include metals that endure rigorous conditions and enhance longevity, showcasing the importance of selecting the appropriate materials to achieve desired results. Moreover, sophisticated surface finishing equipment is crucial in bolstering quality control and ensuring precision in each product crafted, allowing companies like LS Hardware Tech Co., Ltd to maintain their reputation as industry leaders. They offer detailed surface finishing services, ensuring every piece they produce meets the rigorous standards of their diverse clientele spanning over 150 countries.

The surface finishing industry is constantly evolving, driven by technological advancements and increasing demand for high-quality finishes. Companies such as LS Hardware Tech Co., Ltd not only provide products but also empower clients to bring their ideas to life, signifying their mission to remain at the industry's forefront. As an ISO 9001:2015 certified company, LS Hardware is committed to innovative manufacturing solutions, guided by a vision to continually improve processes and capabilities to match consumer needs.

In conclusion, surface finishing techniques are vital in manufacturing, underpinning both the quality and aesthetics of modern products. As technology evolves, so do the methods and materials used in surface finishing, reflected in the innovative solutions provided by industry stalwarts like LS Hardware Tech Co., Ltd. With dedicated expertise and a forward-thinking approach, the company not only meets but anticipates market demands, ensuring their products are always a cut above the rest.

Mastering Surface Finishing Techniques: Revolutionizing Manufacturing Aesthetics

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Surface Finishing, Selective Laser Sintering, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Surface Finishing Techniques for Modern Design

Mastering Surface Finishing Techniques: Enhance Durability & Efficiency

Exploring Surface Finishing Techniques for Modern Design

Mastering Surface Finishing Techniques: Revolutionizing Manufacturing Aesthetics

Advanced Surface Finishing Techniques in Modern Industry

Master Surface Finishing Techniques for Optimal Durability

Unlock Industrial Excellence with Surface Finishing Techniques

Metal Surface Finishing: Essential Techniques and Services