In the ever-evolving domain of modern manufacturing, CNC milling services have carved a niche as pivotal facilitators of precision and efficiency. Leveraging state-of-the-art CNC milling machines and the sophisticated CNC milling process, industries today achieve unprecedented accuracy and intricate designs in their components. With advancements in CNC machining, the production of intricate parts has become not only feasible but also remarkably efficient.

CNC milling services are indispensable, particularly when it comes to the creation of specialized CNC milling parts. The process is beloved in various sectors, ranging from the aerospace and automotive industries to electronics and beyond, where precision CNC milling is a requirement, not a luxury. Its exacting standards ensure that every component—from the bold, yellow cutting-edge component meticulously crafted for performance to custom parts for prototypes—meets and often exceeds industry standards.

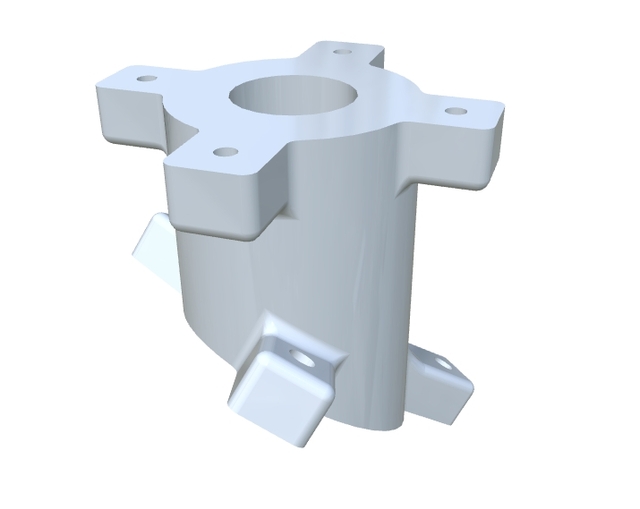

The practical applications of CNC milling are virtually limitless. CNC milling applications stretch far and wide due to their versatility and precision. Whether you're dealing with intricate components that require meticulous attention to detail or robust pieces designed to endure intense operational demands, CNC milling proves to be a reliable solution. The integration of unique design features, such as the conical shape with symmetrical openings to maximize airflow, demonstrates the inventive synergy of form and function that CNC services provide.

In many cases, businesses opt for CNC milling outsourcing to capitalize on expertise and resources that offer cost-effective solutions without compromising on quality. Outsourcing provides access to cutting-edge CNC technologies, professional craftsmanship, and the ability to push boundaries in terms of design and function, such as those seen in advanced mechanical systems seeking both style and enhanced efficiency.

The realm of CNC milling is dynamic, continually pushing technological boundaries while providing industries with the tools to optimize not just products but entire operational approaches. Whether utilized in the development of prototypes or mass production, CNC milling remains at the forefront of modern manufacturing techniques, delivering precision, reliability, and innovation in every cut. Its importance in reducing lead times, improving product consistency, and enabling designs that were once thought unattainable underscores the pivotal role CNC milling services play in today’s industrial landscape. Making the shift towards CNC is not just a step forward; it is a strategic move towards ensuring industry success and competitiveness in a demanding market.

Maximizing Efficiency with CNC Milling Services

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Aluminum CNC Machining: Custom Precision with LS Hardware

CNC Milling Tools: Enhance Your Projects with Precision

5 Axis CNC Milling: Precision Manufacturing Revolution

CNC Milling Services: Precision and Innovation in Manufacturing

CNC Milling Services: Precision Meets Innovation

CNC Milling Machines: Precision Engineering & Design

Custom Metal CNC Milling for Precision Engineering

Custom CNC Milling Services: Precision in Modern Manufacturing

Enhance Precision with Custom CNC Milling Solutions

Custom CNC Milling: Precision Techniques Transforming Industries