In the realm of precision engineering, CNC milling machines stand as an epitome of cutting-edge technology and precision. Designed to cater to a plethora of industrial and custom machinery purposes, CNC milling machines play a pivotal role in crafting components with unparalleled accuracy. With a focus on producing high-performance parts, the CNC milling process is expertly used in fabricating an array of products, including the recently introduced octagonal mounting bracket.

CNC milling services are indispensable in today’s manufacturing landscape. They provide a means to execute complex design specifications with ease and precision. The CNC vertical milling technique, a specific type of CNC milling process, is particularly renowned for its ability to handle a diverse range of materials and geometries, allowing for the production of robust mounting brackets that can withstand rigorous applications.

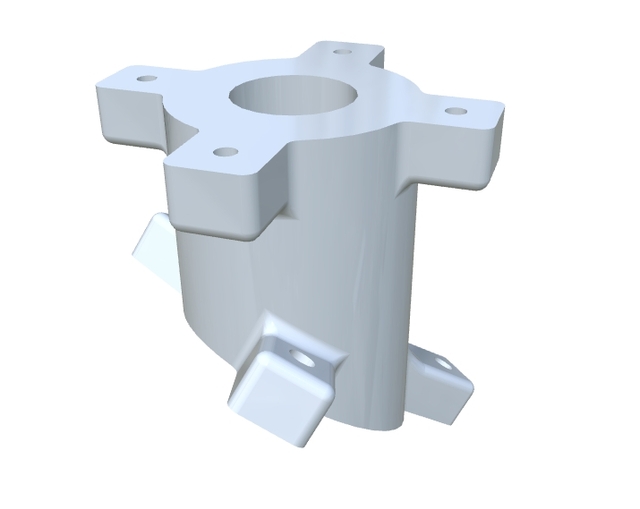

The octagonal mounting bracket, a product of advanced CNC milling, exemplifies the pinnacle of durability and strength due to its cutting-edge design and premium-grade material. Its expertly crafted apertures allow for seamless integration with various hardware components while the strategically placed mounting points facilitate straightforward installation. This makes it a perfect choice for both industrial applications and custom CNC milling projects where adaptability is crucial.

Understanding the CNC milling vs machining distinction is vital for professionals seeking precision and efficiency in their engineering projects. While traditional machining techniques can achieve high levels of detail, CNC milling machines offer unmatched precision and repeatability. This ensures that every fabricated part, including CNC milling parts like the octagonal mounting bracket, meets the exact specifications necessary for advanced engineering applications.

Precision is a hallmark of CNC milling applications, and the octagonal mounting bracket is no exception. Its sleek, durable design provides robust support and stability, redefining the efficiency and performance expected in modern engineering. For professionals committed to innovation and reliability, this bracket offers a balance of strength and adaptability that is essential for tackling the challenges of high-performance applications.

In an industry driven by technological advancement and precision-engineered solutions, CNC milling stands out for its ability to deliver custom CNC milling parts that are both innovative and reliable. As the demand for precision CNC milling continues to grow, products like the octagonal mounting bracket will continue to play a crucial role in supporting the advancement of engineering projects, ensuring that they meet the rigorous standards of today’s marketplace.

CNC Milling Machines: Precision in Engineering Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Aluminum CNC Machining: Custom Precision with LS Hardware

CNC Milling Tools: Enhance Your Projects with Precision

5 Axis CNC Milling: Precision Manufacturing Revolution

CNC Milling Services: Precision and Innovation in Manufacturing

CNC Milling Services: Precision Meets Innovation

CNC Milling Machines: Precision Engineering & Design

Custom Metal CNC Milling for Precision Engineering

Custom CNC Milling Services: Precision in Modern Manufacturing

Enhance Precision with Custom CNC Milling Solutions

Custom CNC Milling: Precision Techniques Transforming Industries