In the modern world of engineering and manufacturing, rapid prototyping techniques stand at the forefront of innovation, enabling creators to bring concepts to life quickly and efficiently. These techniques revolutionize the way products are designed and evaluated, offering immense flexibility in the development process. At LS Hardware Tech Co., Ltd, we recognize the transformative power of these methods and have integrated them into our cutting-edge vented electronics enclosure—a product that exemplifies the benefits and potentials of rapid prototyping.

Rapid prototyping techniques such as agile prototyping methods and 3D printing prototyping have become essential tools in the iterative design process. These approaches allow designers to efficiently create and refine prototypes, minimizing the time between initial concept and final product. Utilizing prototyping materials that are both cost-effective and adaptable, these techniques empower teams to experiment freely, leading to enhanced innovation and creativity. The result is a development process that is both effective and responsive to the needs of modern technology-driven markets.

LS Hardware Tech Co., Ltd, established by the visionary Mr. Nick Zhang, stands as a testament to the power of expert engineering and precise manufacturing. With over 20 years of experience in the field, Nick and his team have cultivated a reputation for delivering efficient solutions to a wide array of industries. Our commitment to quality and innovation is embodied in the ISO 9001:2015 certification that we proudly hold, ensuring that every product we create meets the highest standards of excellence.

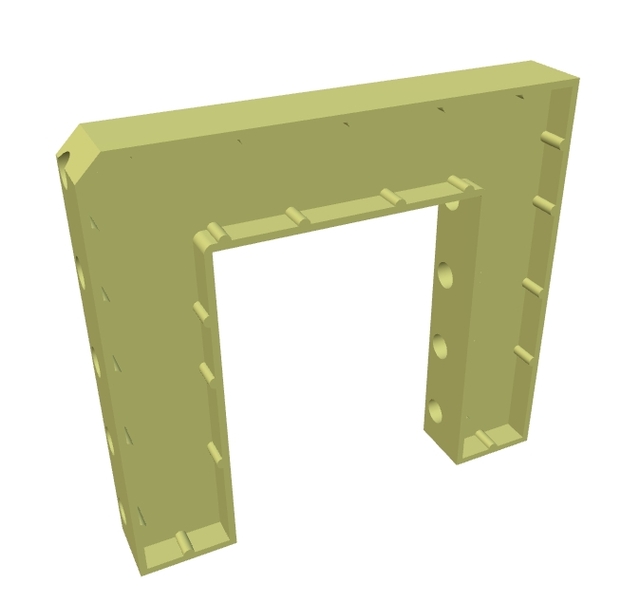

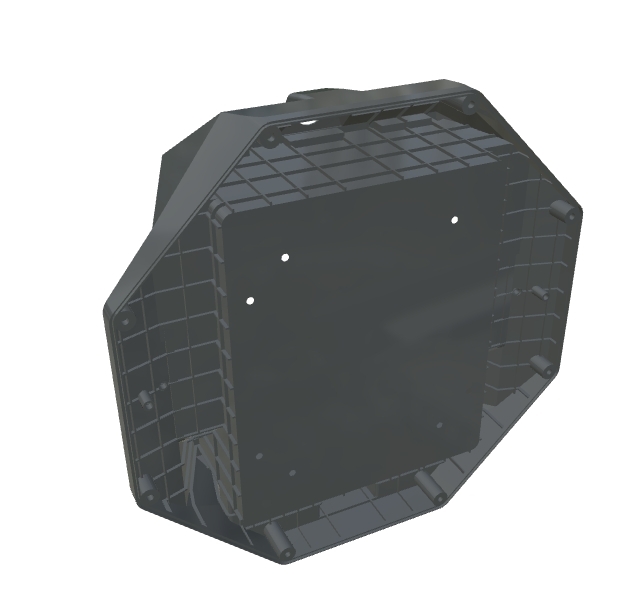

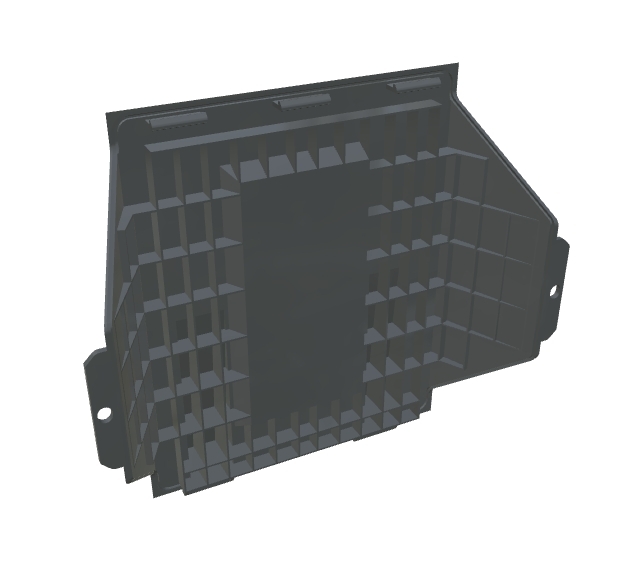

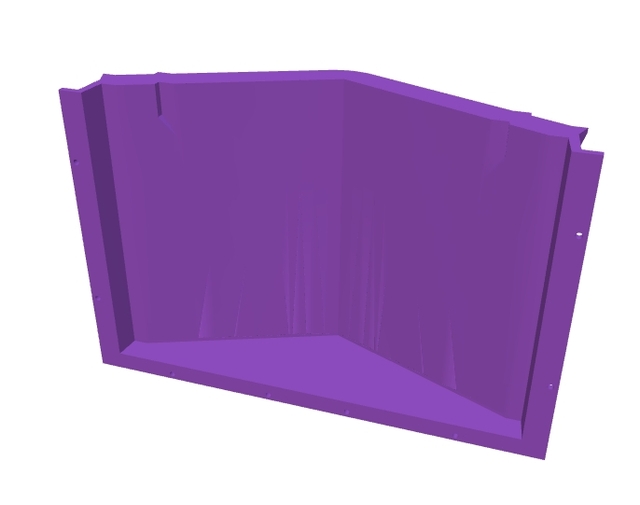

Our flagship product, the vented electronics enclosure, offers optimal functionality paired with a sleek, modern design. This enclosure features strategically placed ventilation grids that are meticulously arranged to ensure ideal airflow for sensitive electronic components—a critical factor in maintaining performance and durability. Crafted from robust materials, this enclosure not only provides durable protection but also integrates seamlessly into any environment with its contemporary geometric aesthetic. Whether utilized in industrial applications or high-tech personal projects, our enclosure promises to exceed the demands of today's tech innovators.

Moreover, our adept use of low-cost prototyping and hardware prototyping demonstrates our ability to cater to diverse market needs. From automotive and medical devices to consumer electronics and aerospace, the adaptability of LS's methodologies ensures that we can support a broad spectrum of industries through all stages of product development—from initial prototypes to mass production. Our state-of-the-art factory, equipped with over 100 high-end machining centers, represents our commitment to leveraging technology to provide high production efficiency and unmatched product quality.

Software prototyping tools further complement our manufacturing processes. By incorporating these digital solutions, our team is able to develop and test products in virtual environments before physical production begins. This not only reduces costs but also allows us to pinpoint and address potential issues early, ensuring that the final product not only meets but surpasses client expectations.

At LS Hardware Tech Co., Ltd, our mission is underscored by a relentless pursuit of innovation. We strive to empower our clients, providing them with the tools and expertise needed to transform ideas into reality. By staying at the cutting edge of technological advancements, we are committed to continually refining our processes and capabilities, ensuring that we remain a trusted partner in the pursuit of excellence. As rapid prototyping techniques continue to evolve, we stand ready to harness their potential, delivering products that inspire and propel future innovations.

Mastering Rapid Prototyping Techniques for Tech Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Rapid Prototyping, Rapid Prototyping Design, Rapid Prototyping Manufacturing, Prototype Testing and Validation , Post-Processing Services |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.