In today's fast-paced world, innovation and speed are key to maintaining a competitive edge. One of the leading methods in achieving this is through **rapid prototyping techniques** - a transformative approach that revolutionizes how products are developed and brought to market. Rapid prototyping encompasses various methods and processes used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. This technique is indispensable in industries ranging from automotive to medical devices for its ability to transform ideas into tangible prototypes swiftly and efficiently.

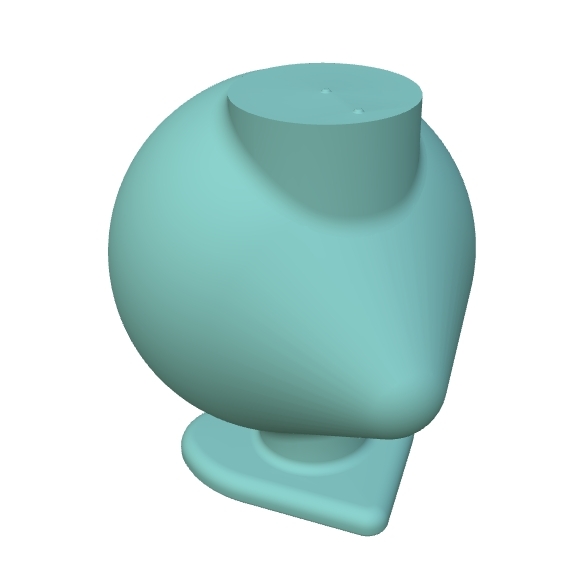

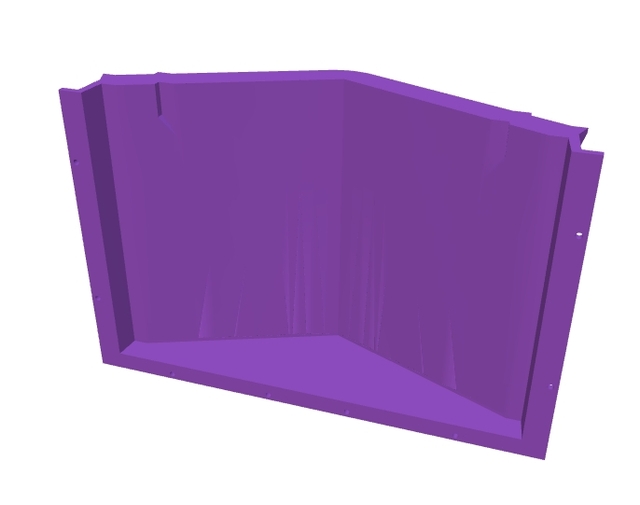

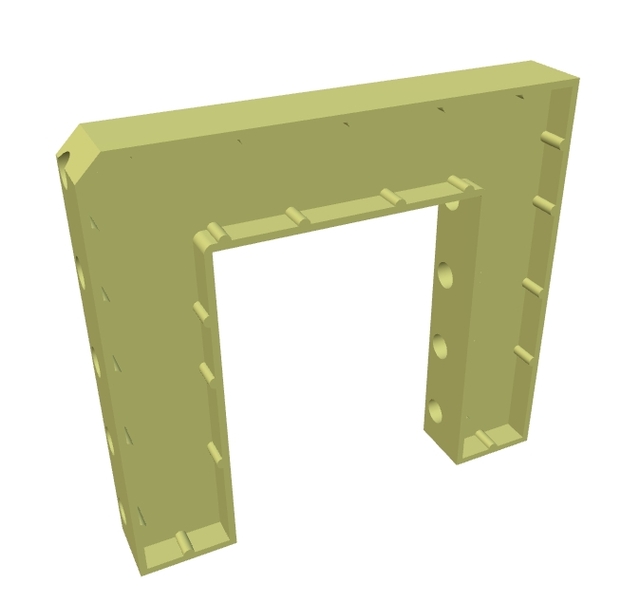

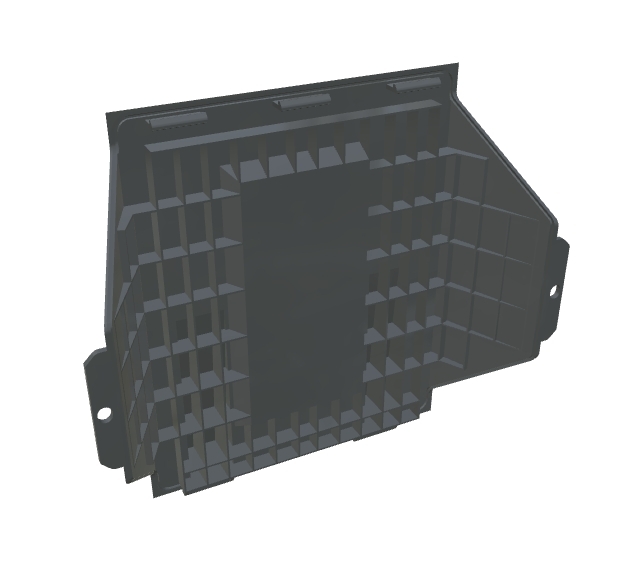

Among the various **rapid prototyping services** available, 3D printing stands out as a game-changer. This technique not only enables the creation of complex shapes that would be impossible with traditional manufacturing methods, but it also allows for modifications and iterations at a fraction of the cost and time. By using **3D printing rapid prototyping**, companies can quickly test their designs, assess the fit and functionality, and make necessary adjustments before mass production. Such agility is particularly valuable in industries with rapidly changing demands where innovation must keep pace with shifting market needs.

Integral to the process of **rapid prototyping** is the software that supports it. Modern **rapid prototyping software** provides designers and engineers the ability to visualize designs in three dimensions and simulate their behavior under real-world conditions. This capability helps in refining designs by identifying potential issues or areas of improvement before the prototype is even built. The benefits of this approach are manifold, contributing to reduced production costs, enhanced product quality, and faster time to market.

The **benefits of rapid prototyping** extend beyond speed and cost-efficiency. For instance, it allows for early and frequent testing of a design concept, providing insights into user experience and product performance well in advance of production. Moreover, it facilitates communication and collaboration among team members, stakeholders, and clients by providing a tangible representation of the product that everyone can evaluate and discuss.

Industries such as automotive, aerospace, electronics, and healthcare have embraced rapid prototyping techniques due to their flexibility and effectiveness. For example, automotive manufacturers use rapid prototyping to test the aerodynamics and aesthetics of new models, while the medical industry leverages the technology for creating anatomical models and custom implants that enhance patient care.

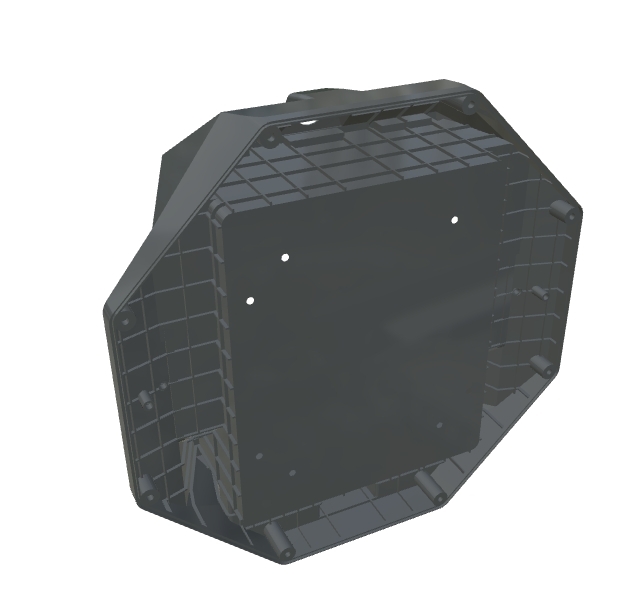

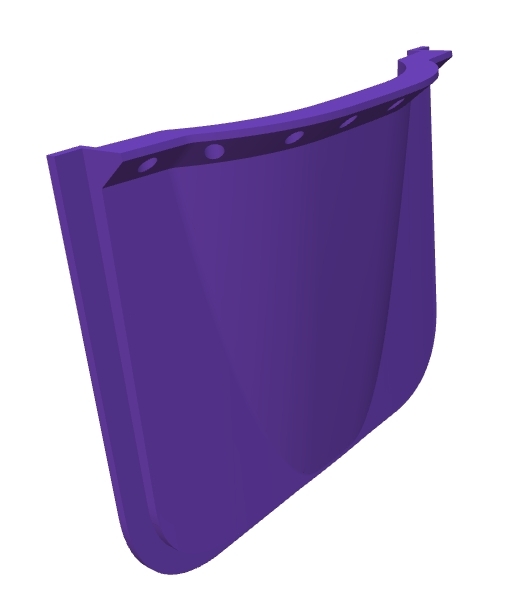

Here at LS Hardware Tech Co., Ltd, we recognize the critical role that rapid prototyping plays in product development. Founded by Mr. Nick Zhang, our company has over two decades of experience in manufacturing high-precision hardware and plastic parts. Our state-of-the-art facility, equipped with more than 100 high-end machining centers, enables us to provide **custom rapid prototyping** solutions tailored to the specific needs of our clients across various industries, from prototypes to mass production.

Our flagship product, the Precision Mounting Ring, exemplifies our commitment to innovation and quality. Designed for durability and precision, this component is ideal for applications requiring secure fastening and alignment. Made using advanced **rapid prototyping materials**, the mounting ring withstands high torque and resists wear, making it a reliable choice for automotive, industrial, and DIY projects.

In addition to our cutting-edge products, LS Hardware Tech Co., Ltd is committed to excellent customer service and technological advancement. Our ISO 9001:2015 certification underscores our dedication to quality and continuous improvement. By staying at the forefront of **industries using rapid prototyping**, we empower our clients to turn their ideas into reality, ensuring they stay competitive in their respective fields.

In conclusion, as industries continue to evolve, the need for fast, reliable, and cost-effective design methods will only grow. **Rapid prototyping techniques** provide a framework that not only meets these needs but exceeds them, opening new possibilities for innovation and creativity. Companies like LS Hardware Tech Co., Ltd are at the helm of this transformation, leading with expertise and a commitment to delivering **rapid prototyping services** that propel industries towards a future where boundaries are merely suggestions.

Exploring Rapid Prototyping Techniques for Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Rapid Prototyping, Rapid Prototyping Design, Rapid Prototyping Manufacturing, Prototype Testing and Validation , Post-Processing Services |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.