Imagine walking into a space where precision and innovation meet elegance. LS Hardware Tech Co., Ltd, a company renowned for its high-efficiency machining centers and ISO 9001:2015 certification, presents its cutting-edge **CNC turning parts**—a harmonious convergence of artistry and advanced engineering. In an era when craftsmanship and efficiency are more essential than ever, LS Hardware Tech stands as an industry leader, trusted by major factories in over 150 countries.

The journey of crafting CNC turning parts is a story that begins with meticulous planning and a deep commitment to quality. The **CNC turning process** represents more than just machinery spinning metal; it is about achieving perfection through state-of-the-art technologies. For industries such as automotive, medical devices, consumer electronics, aerospace, and industrial equipment, LS Technology employs **high precision CNC turning** to create components that are integral to modern innovations.

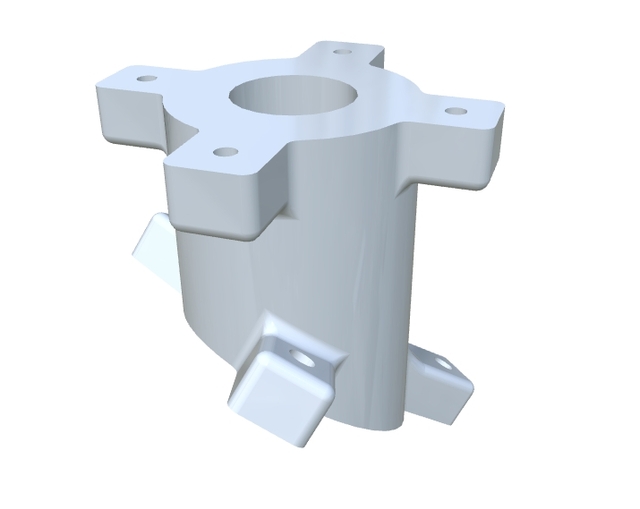

Picture the **Mono-Cylinder Utility Hub**, a masterpiece engineered with precision in every curve. Crafted with a smooth cylindrical form and a matte graphite-gray finish, it embodies contemporary design while offering endless potential applications. This CNC turning part, like many others, is designed with versatility at its core. Whether it serves as a modular base for complex equipment or injects sophistication into interior décor, it’s clear that **CNC lathe services** are instrumental in producing parts that balance visual beauty and functional expertise. LS Hardware Tech's advanced tooling and machining centers ensure each piece adheres to the highest standards of **CNC turning quality assurance**.

As LS Technology brings this craftsmanship to life, it also introduces the **Multi-Zone Silicone Tray**, which showcases how **CNC machining and turning** can deliver innovative simplicity. With its dual-layer structure and seamless form crafted from eco-friendly silicone, this tray is an example of how custom CNC machining refines everyday objects into extraordinary tools. Whether for holding steaming beverages or displaying treasured accessories, the tray’s durability matches its aesthetic charm. This product speaks volumes about LS Hardware Tech’s ability to merge cutting-edge processes with sustainable and consumer-friendly designs.

But LS Technology’s range doesn’t end there. The **Essence Cylinder** adds another dimension to its CNC precision turning prowess. With a matte charcoal finish and multi-application versatility, this minimal yet durable cylindrical container defies expectations with its subtle elegance. It’s not merely a product—it’s a testament to LS Tech’s innovative capabilities, showcasing their commitment to creating solutions tailored to diverse industries and lifestyles.

Behind the scenes, LS Hardware Tech Co., Ltd excels in more than just manufacturing components; it crafts possibilities. The company combines brilliance in **custom CNC machining** with a mission to deliver innovative manufacturing solutions to its clients. Equipped with over 100 high-end machining centers, LS Hardware Tech takes concepts from prototypes to mass production, adapting to the ever-evolving needs of consumers. Their expertise has made them a trusted name globally, providing reliable solutions for sectors where high precision determines success.

The story doesn’t end with the products—it extends into the rigorous processes behind them. LS Tech’s **CNC turning process** helps solve challenges in industries requiring meticulous engineering. Whether it’s crafting parts for aerospace innovations or medical tools, the results are consistent: flawless, efficient components tailored to perfection. With high-quality design, **CNC turning parts** created by LS Hardware Tech embody durability and reliability.

The design and manufacturing of CNC turning parts showcase more than skill; they reflect a fascination with detail and innovation. From the luxurious simplicity of the Mono-Cylinder Utility Hub to the practical charm of the Multi-Zone Silicone Tray, each piece represents LS Technology’s ability to merge art and industry. And products like the Essence Cylinder remind us that understated designs often hold the most utility.

LS Hardware Tech is more than a company—it’s a bridge to new possibilities. By specializing in **CNC precision turning**, they support industries where precision isn’t optional; it’s essential. Their dedication to **CNC lathe services**, combined with their advanced technology and quality assurance, drives unparalleled craftsmanship. And every piece sent to factories worldwide reflects a mission to deliver excellence.

In an age of rapid innovation, LS Hardware Tech exemplifies how precision manufacturing shapes the future. Their commitment to providing **custom CNC machining** solutions adds value to clients, enabling them to realize their ideas through precision and care. And behind every turning process lies the expertise and high-quality service demanded by top industries globally.

For those searching for reliability in manufacturing and elegance in design, LS Hardware Tech Co., Ltd has more than earned its place in the global market. **CNC turning parts** crafted by LS Technology are not just products—they are works of art molded by technology, delivering precision for today’s and tomorrow’s challenges.

CNC Turning Parts Redefine Precision & Versatility

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Turning |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

CNC Turning Service Quotes for Precision Engineering

CNC Lathe Services for Precision Manufacturing Needs

Customized CNC Turning Solutions for Precision Engineering

Exploring CNC Turning Material Options for Precision

CNC Machining Services: Precision Turning for Modern Manufacturing

CNC Turning Parts Redefine Precision & Versatility

Custom CNC Turning Services: Precision Meets Innovation

Custom Machining Solutions: Innovative CNC Turning Excellence

Custom Machining Services by LS Hardware Tech Co., Ltd.

CNC Part Manufacturing Services: Precision Meets Innovation