Choosing the right CNC turning material options can be the defining factor in achieving industrial perfection. The Absolute Ring and Precision Torque Seal Ring are prime examples of how material choices and precise engineering can impact mechanical performance and functionality. With LS Hardware Tech Co., Ltd leading the charge in manufacturing innovation, these products are setting new benchmarks in high-performance engineering. In this article, we’ll explore the importance of material selection for CNC turning, highlight the key features of these exemplary products, and share how these innovations are changing the game for industries worldwide.

Material selection is one of the most critical aspects of the CNC turning process. LS Hardware Tech Co., Ltd, a company operating with 100+ high-end machining centers and ISO 9001:2015 certification, understands this deeply. As a trusted global partner capable of manufacturing high-precision parts for industries like aerospace, automotive, and medical devices, LS Hardware knows that material choice can make or break a project. When it comes to CNC turning for construction or applications requiring airtight connections, the selection of materials like stainless steel, aluminum alloys, or high-strength plastics ensures durability and reliability even under demanding conditions. These material options provide robust solutions for industries looking to optimize performance and reduce inefficiencies in their systems.

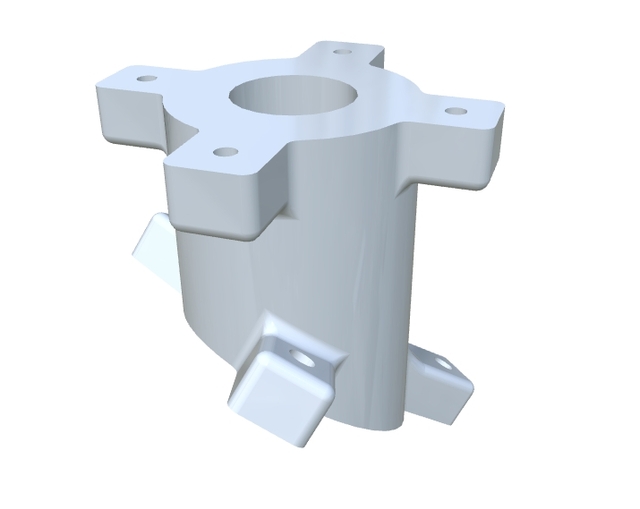

The Absolute Ring represents the epitome of functionality in CNC turned components. Crafted from high-grade materials, this sleek circular structure serves as a gasket or sealing component to prevent leaks and ensure smooth mechanical operations. With its uniform geometry and meticulous attention to detail, this ring excels in applications where precision is paramount. Its robust design is engineered to resist pressure, temperature fluctuations, and wear over time, making it indispensable for industries like automotive and aerospace. The modern matte gray finish not only enhances the aesthetic appeal but integrates seamlessly into machinery, ensuring that functionality doesn’t compromise style. For businesses looking for reliability and longevity in industrial designs, the Absolute Ring is a beacon of precision-engineered brilliance.

Similarly, the Precision Torque Seal Ring is a marvel of minimalist design combined with high-grade performance engineering. Its streamlined, beveled profile and durable material make it a highly effective solution for sealing mechanisms, rotational joints, and precision machinery. Designed for snug fits and optimized torque transmission, this ring eliminates friction-based inefficiencies while enhancing operational accuracy. Whether powering next-generation robotics or securing fluid dynamics in aerospace systems, the Precision Torque Seal Ring undeniably raises the standards of industrial solutions. With its sleek matte finish designed for wear resistance and visual sophistication, this product exemplifies two essential principles: durability and elegance.

LS Hardware Tech Co., Ltd continues to garner attention not just for its exceptional products but also for its steadfast commitment to customer satisfaction. From prototypes to mass production, the company's dedication to quality control, innovation, and adaptability shines through. By specializing in online CNC turning services, LS Technology makes accessing high-performance components like the Absolute Ring and Precision Torque Seal Ring easier for small businesses and major factories alike. The company's goal is to help clients realize their design ideas, continually improving processes to meet diverse customer demands worldwide. Positive CNC turning service testimonials further attest to LS Tech's reputation as a reliable and forward-thinking partner.

When it comes to CNC turning for construction or small-business ventures, LS Hardware Tech Co., Ltd ensures every detail is accounted for in its material selection process. The company understands that the right material choice allows for versatile applications, whether isolating vibrations, creating airtight seals, or enabling smooth torque transmissions. These components embody a philosophy of sophisticated simplicity—proving that elegance can coexist with industrial ruggedness. Furthermore, CNC turning project management by LS Technology ensures timely delivery and exceptional quality for every order, enabling businesses to stay ahead in an increasingly competitive landscape.

In conclusion, the CNC turning material options provided by LS Hardware Tech Co., Ltd pave the way for industries requiring high-performance precision components. By choosing the Absolute Ring and Precision Torque Seal Ring, businesses are not merely investing in mechanical parts; they are embracing a commitment to top-quality engineering and industrial innovation. These products, combined with LS Tech’s dedication to excellence, redefine what it means to create solutions that balance efficiency, precision, and timeless design. Whether for construction, automotive engineering, or small-scale manufacturing, LS Hardware Tech Co., Ltd ensures your CNC turning requirements are met with expertise and reliability. Customers looking to explore cutting-edge production methods will find LS Hardware Tech a seamless extension of their goals, driving their projects toward unparalleled success.

Exploring CNC Turning Material Options for Precision

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Turning |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

CNC Turning Service Quotes for Precision Engineering

CNC Lathe Services for Precision Manufacturing Needs

Customized CNC Turning Solutions for Precision Engineering

Exploring CNC Turning Material Options for Precision

CNC Machining Services: Precision Turning for Modern Manufacturing

CNC Turning Parts Redefine Precision & Versatility

Custom CNC Turning Services: Precision Meets Innovation

Custom Machining Solutions: Innovative CNC Turning Excellence

Custom Machining Services by LS Hardware Tech Co., Ltd.

CNC Part Manufacturing Services: Precision Meets Innovation