As an important fabrication process,sheet metal fabrication is widely used in aerospace, automotive, construction and home appliance manufacturing industries. In the sheet metal fabrication process, mastering key design and engineering considerations is critical to improving product quality, reducing fabrication costs, and ensuring production efficiency. This article will focus onkey design and engineering considerations in sheet metal fabrication.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a metal processing and forming process. It mainly uses metal sheet materials with a thickness of less than 6mm to produce parts, components or structural parts througha series of cold fabrication processes (such as cutting, bending, stamping, welding, surface treatment, etc.). Products made of sheet metal are widely used in automobiles, aerospace, electronic equipment, construction, medical equipment, communications, electronic appliances and other fields, such as car casings, computer cases, mobile phone metal parts, etc.

How Does the Sheet Metal Fabrication Process Work?

Step 1: Design and prototype using CAD software

Use computer-aided design (CAD) software to perform detailed design of sheet metal parts based on customer needs and project requirements. The size, shape, material, thickness and subsequent processing and assembly requirements of the sheet metal parts need to be considered during the design process.

Verify and modify the design throughrapid prototyping technology(such as 3D printing) or hand-made models to ensure that the design meets actual needs.

Step 2: Select materials based on project requirements

Select the appropriate material from a variety of sheet metal materialsbased on project requirements. Common sheet metal materials include cold-rolled sheets, galvanized steel sheets, stainless steel, aluminum, etc. When selecting materials, factors such as material strength, corrosion resistance, processing performance, and cost need to be considered. After determining the materials, proceed with material procurement. Ensure that purchased materials meet design requirements and have corresponding quality certification documents.

Step 3: Cut, Bend, and Shape the Metal into Shape

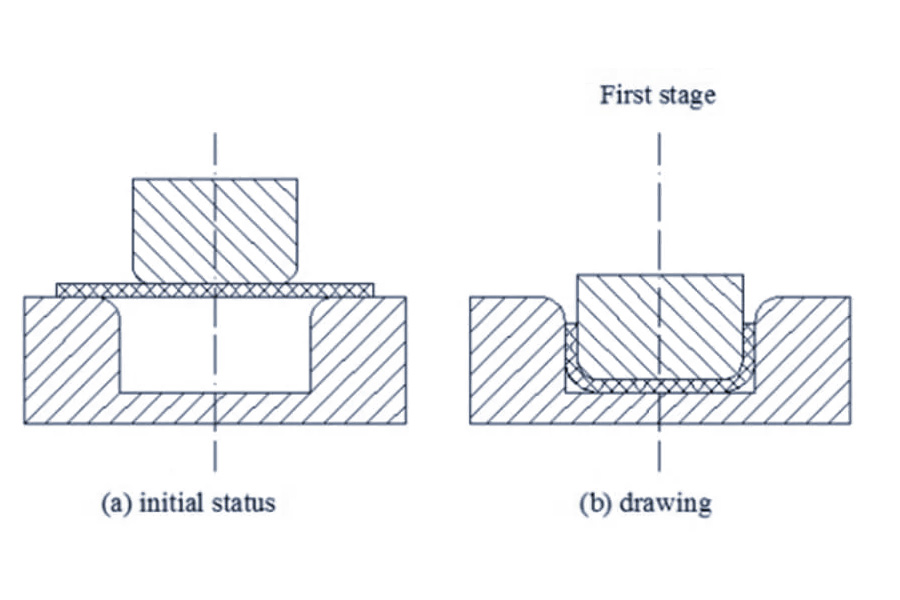

Use equipment such aslaser cutters, shears, or punches to make precise cuts of materials. Cutting accuracy and edge quality need to be ensured during the cutting process. Next, equipment such as a bending machine, plate rolling machine or mold is used to bend and shape the cut material. During the molding process, the bending angle, bending radius and forming accuracy need to be controlled.

Step 4: Weld and Assemble Parts

Use welding equipment (such as TIG welding, MIG welding, resistance welding, etc.) to weld sheet metal parts. During thewelding process, welding seam quality, welding strength and welding deformation control need to be ensured. Assemble the welded parts to form a complete sheet metal part. During the assembly process, it is necessary to ensure the fit accuracy and assembly quality between parts.

Step 5: Finishing operations such as painting, powder coating and polishing

Surface treatment of sheet metal parts, such as sandblasting, rust removal, pickling, etc.,to improve surface quality and adhesion. Sheet metal parts are painted or powder coated according to customer requirements. Painting and powder coating can protect sheet metal parts from corrosion and wear while improving aesthetics. Polish and sand sheet metal parts to improve surface finish and gloss.

What Are the Key Material Considerations in Sheet Metal Fabrication?

1.Material Selection

In sheet metal fabrication, the choice of materials is crucial, because different metal materials have different physical and chemical properties, which directly affect the selection of processing technology and the performance of the final product. Here are some commonly used materials and their characteristics:

- Aluminum plate:Aluminum is a silvery-white light metal with good thermal conductivity, electrical conductivity and ductility, low density, light weight, and good corrosion resistance. Therefore, aluminum sheets are often used in applications that require weight reduction and corrosion resistance, such as aerospace, automotive, marine, and other fields.

- Galvanized sheet:Galvanized sheet is a sheet that is plated with a layer of zinc on the surface of the steel plate to improve its corrosion resistance and service life. Galvanized sheet is divided into hot-dip galvanized sheet and electro-galvanized sheet, among which hot-dip galvanized sheet has good corrosion resistance and high strength, and is suitable for use in harsh environments; The electro-galvanized sheet has good surface gloss and good processing performance, and is suitable for occasions with high requirements for surface quality.

- Stainless steel:Stainless steel is a special alloy steel that has excellent resistance to corrosion and high temperatures. Because of its high hardness and good toughness, it is widely used in industry. It is characterized by its sturdyness, cost-effectiveness, and relative ease of processing and welding. Due to the wide range of applications in industry, stainless steel is also known as the "king of metals". Stainless steel is often used in items that require corrosion resistance and cleaning, such as food handling equipment and medical devices.

- Carbon steel:This is a kind of steel that is mainly composed of carbon. According to the difference in carbon content, it can be classified into low carbon steel, medium carbon steel and high carbon steel. Low carbon steel can be divided into two types: ordinary carbon steel and low alloy steel. Carbon steel has been widely used in many fields such as machinery and construction due to its advantages of high strength and low cost.

2.Thickness and Gauge Chart

Sheet metal spec drawings can be used to determine the thickness of the sheet, which has a significant impact on processing techniques and the performance of the final product. For automobile manufacturing companies, in order to ensure the quality and service life of parts, they usually use different materials to make sheet metal parts to achieve design effects. Generally, the thicker the sheet, the stronger and stiffer it is, but this also means that the difficulty and cost of processing will increase. In addition, for some specific parts, plate thickness and dimensional accuracy are mutually restrictive. Therefore, when deciding the thickness of the board, the functional requirements of the product and the manufacturing process must be comprehensively considered. In addition, specification drawings can also show details such as the specific size and shape of the board, which is very helpful in formulating processing and production plans.

3.Surface Finishes and Coatings

In order to enhance the durability of the panel and improve its appearance quality,surface treatment and coating are particularly critical. In order to ensure that the product has good performance, appropriate technical measures must be adopted during the design and manufacturing process to control surface properties and prevent surface damage. Listed below are several common surface treatments and coating technologies:

(1) Galvanizing:Galvanizing is a commonly used anti-corrosion method to improve the corrosion resistance of the steel plate by coating it with a layer of zinc on the surface. The galvanized layer can protect the steel plate from oxidation, corrosion, etc., and prolong the service life.

(2) Spraying:Spraying is a coating process that adheres powder-type paint to the working surface through corona discharge. After spraying, a uniform, flat and smooth coating can be formed, which improves the durability and appearance quality of the plate. At the same time, spraying can also choose different colors and textures according to needs to meet different decoration requirements.

(3) Oxidation:Oxidation is a surface treatment method that forms a protective film on the surface of a metal. Through oxidation treatment, a dense oxide film can be formed on the surface of the metal, which improves its corrosion resistance and wear resistance.

(4) Other treatment methods:In addition to galvanizing, spraying and oxidation, surface treatment methods such as electroplating, electrophoresis, and dip molding can also be used to improve the durability and appearance quality of the plate. These methods can be selected and applied according to specific needs.

What Are the Essential Design Considerations for Sheet Metal Parts?

1.Bend Radius and Bending Sheet Metal

- Bending radius:The size of the bending radius has an important impact on the forming quality and strength of sheet metal parts. A bend radius that is too small may cause the material to crack during the bending process, while a bend radius that is too large may increase the size and weight of the part. During the design process, the appropriate bend radius should be selected based on the type of material, thickness, and required strength.

- Bending sheet metal:Bending is a common process in sheet metal processing, through which various required shapes and structures can be formed. When designing bent sheet metal, factors such as the bending direction, angle, and dimensional accuracy after bending need to be considered.

2.Bend Allowance and K-Factor

- Bending allowance:Bending allowance refers to the extra lengthreserved to compensate for the deformation of the material during bending. By calculating the bending allowance, you can ensure that the dimensional accuracy of the part after bending meets the design requirements.

- K Factor:The K factor is an empirical constant used to describe the position of the neutral line of a material during bending. The size of the K factor depends on factors such as material type, thickness, and bending method. By understanding the influencing factors and calculation methods of K factor, thebending deformation of sheet metal partscan be better controlled and the forming quality improved.

3.Tolerance and Fit

- Tolerance:Tolerance refers to the allowable range of variation in the dimensions of a part. When designing sheet metal parts, a reasonable tolerance range should be set based on the use and assembly requirements of the part. Too large a tolerance may lead to poor fit between parts, affecting assembly accuracy and performance; too small a tolerance may increase processing difficulty and cost.

- Fit: fit refers to the relative position and connection between parts. During the design process, the fit and accuracy requirements between parts need to be considered to ensure that the assembled parts can work properly.

4.Hole and Slot Placement

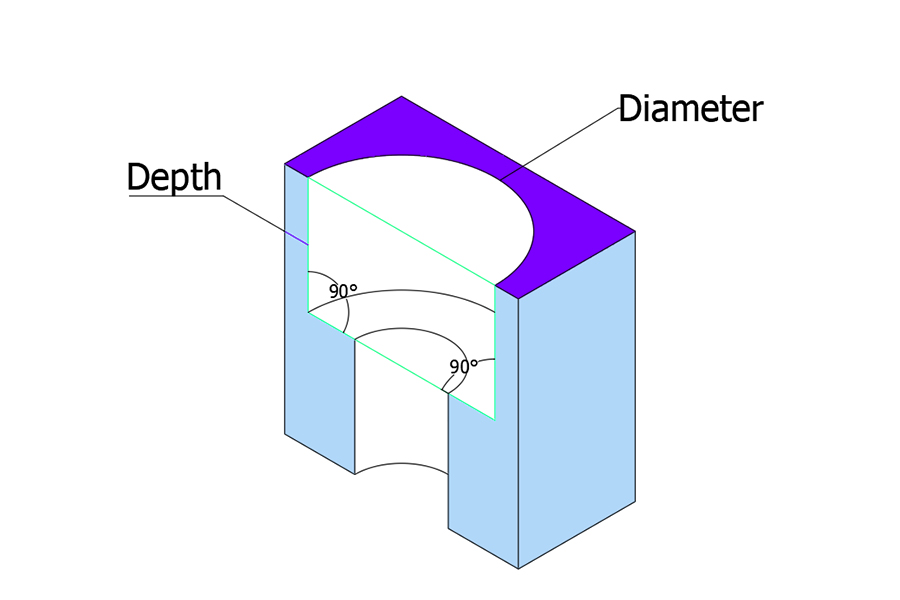

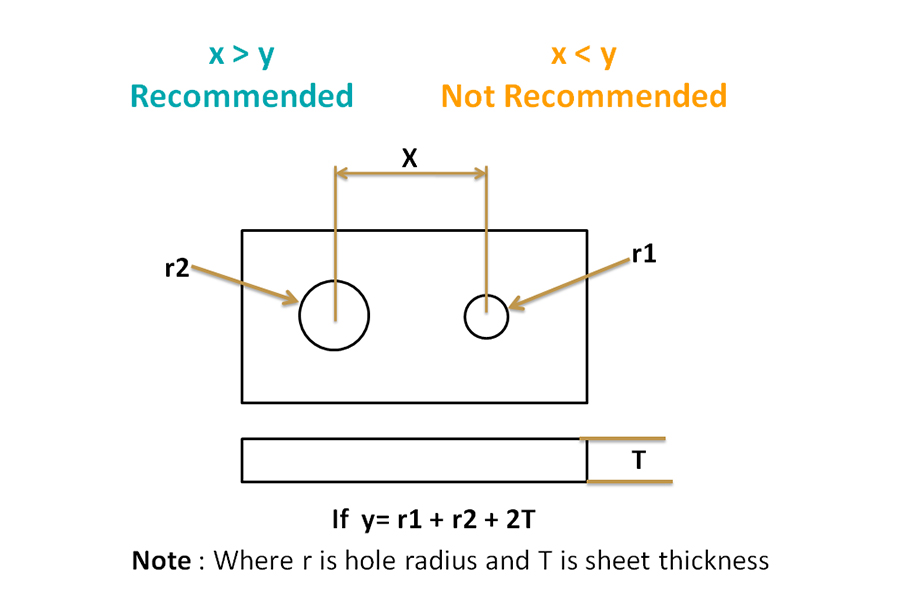

- Hole Placement:The position of holes has an important impact on the structural strength and assembly accuracy of sheet metal parts. During the design process, avoid designing holes near the bending area to prevent the holes from deforming or breaking during the bending process. At the same time, the distance and arrangement between holes also need to be considered to ensure the structural strength and assembly accuracy of the parts.

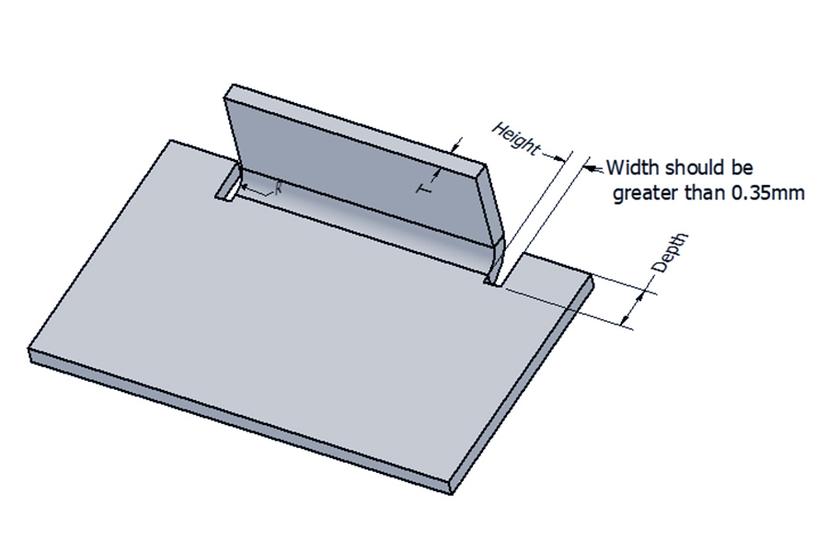

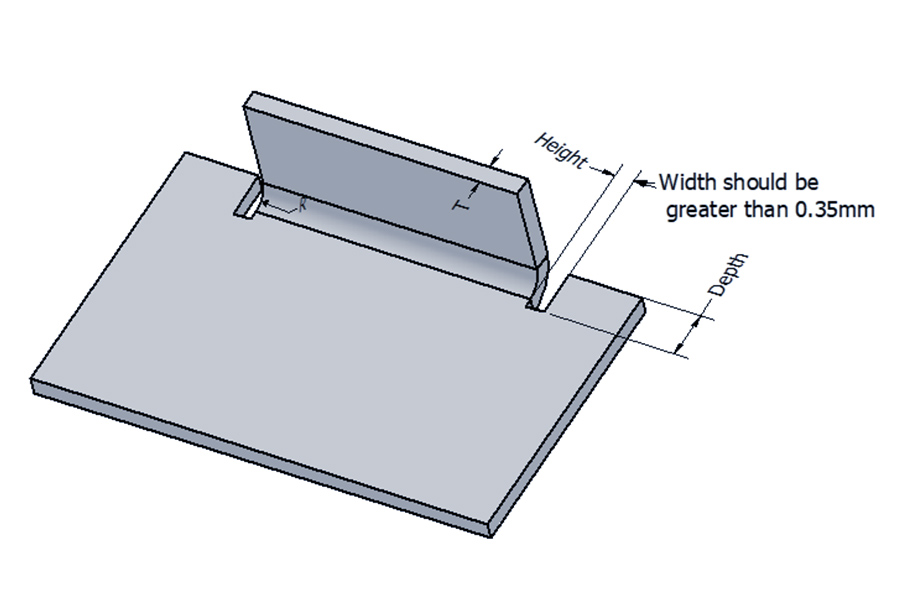

- Slot Placement: The design of the slot also needs to consider the impact of its location on the part. Similar to holes, avoid designing slots near the bend area to prevent the slot from becoming deformed or damaged during the bending process.

How to Ensure Structural Integrity and Functionality in Sheet Metal Design?

1.Stiffening Features

(1) Reinforcement design:Increasing the thickness and height of the plate, as well as the cross-cutting area, is the basic method to improve the stiffness of sheet metal parts. The use of high-strength, high-toughness, low-modulus materials, such as high-strength low-alloy steel, aluminum alloy, magnesium alloy, etc., can significantly improve the strength and stability of components. Adding stiffeners or angle irons to the connecting ends of sheet metal parts can further enhance the support force.

(2) Stiffness enhancement measures:through hot forming, cold forming, forging, quenching and other processes, the grain of the material is more fine, so as to improve the strength and toughness. Ensure the uniformity of the material during the processing process and avoid excessive stretching andbending to reduce deformation and defects.

2.Minimizing Stress Concentration

(1)Reduce stress concentration:Stress concentration is the main cause of local fragility, deformation and displacement of sheet metal parts. During design, sharp corners and excessive shape changes should be avoided to reduce the possibility of stress concentration. Optimize the inner and outer corner radii to make the corners smoother, helping to disperse stress and reduce concentration.

(2)Finite element analysis method:Using finite element analysis method to simulate and analyze sheet metal parts, we can predict possible local fractures, surface wrinkles, local thinning and other production deficiencies, thereby guiding design optimization. By optimizing the model, the stiffness, strength and modality of sheet metal parts can be further improved, and the impact of stress concentration can be reduced.

3.Edge and Corner Treatments

(1)Edge Treatments: When working with sheet metal, keeping corners as closed as possible is a critical step. This helps reduce the amount of welding and filling work required, improving production efficiency and product quality. Corner closure can also reduce stress concentration and improve the strength and stability of sheet metal parts.

(2)Corner Treatments: Enabling the corner processing function in the design software can make the corners more material and the shape closer to 90 degrees, thereby enhancing the strength and stability of the corners. Flexibly choose whether to turn on the corner processing function according to the materials used, manufacturing machinery and process requirements.

4.Using Flanges and Tabs

(1)Increase the support structure:The introduction of flanges and protrusions in the design can increase the support structure of the sheet metal parts and improve the overall strength and stability. Flanges and tabs can also be used as connecting and fastening components, improving the accuracy of component positioning during assembly.

(2)Optimize assembly efficiency:Flanges and tabs should be designed with ease and efficiency in mind. Proper flange and tab layout can simplify the assembly process and reduce assembly time and cost.

Longsheng: Your Trusted Sheet Metal Fabrication Design Company

At Longsheng, we are not only proficient in the various skills mentioned above, but we have a professional technical team that can provide leading sheet metal fabrication services to manufacture high quality parts for you at very competitive prices. As an ISO 9001:2015 certified company, we focus on the construction of quality management system to provide customers with reliable service.

Our team of experts has the experience to perform DfM (Design for Manufacturability) analysis to improve your design. We are not only a manufacturer, but also a partner, committed to providing full support and professional advice to our customers to ensure that the design can reduce manufacturing costs while still meeting high quality standards.

If you have a design model that needs to be manufactured, please upload it to us immediately and wewill provide you with an immediate quote. Choose Longsheng, choose a quality, high technical level, cost-effective sheet metal fabrication partner, let us work together to create outstanding parts for your project to achieve greater success.

FAQs

1.What types of materials are best for sheet metal fabrication?

Commonlyused materials for sheet metal fabricationinclude cold-rolled steel sheets, electro-galvanized cold-rolled steel sheets, hot-dip galvanized steel sheets, aluminum-zinc-coated sheets, stainless steel sheets, rust-proof aluminum sheets, aluminum alloy sheets, copper and brass, etc. When selecting materials, comprehensive considerations need to be made based on factors such as the product's functional requirements, usage environment, and cost budget.

2.How do I choose the right bend radius for my design?

Choosing the rightbend radius for a sheet metal designrequires several factors to consider, including the thickness of the material, the pressure of the press brake, and the width of the die groove under the bending die. In general, when the sheet thickness is less than 6 mm, the inner radius of the sheet bending can be directly determined by the sheet thickness. When the plate thickness is greater than 6mm and less than 12mm, the bending radius of the plate is generally 1.25-1.5 times of the plate thickness. When the plate thickness is greater than 12mm, the bending radius in the plate is generally 2-3 times of the plate thickness. The width of the die groove under the bending die has a certain relationship with the size of the bending radius. The smaller the groove width, the smaller the bending radius; The larger the groove width, the larger the bend radius.

3.What are common mistakes to avoid in sheet metal design?

Insheet metal design, the main common mistakes that should be avoided are: ① Avoid placing holes, tabs and other features too close to the bend line to prevent deformation or damage during the bending process. It is recommended to follow the 4T rule, which is to keep all features at least four times the thickness of the material away from the bend line. ② When designing, the strength of the material and its ease of bending need to be considered. For example, stronger materials may require a larger bend radius or a more complex bending process.③ Ensure that the welding requirements are practical and avoid difficult-to-operate situations such as welding in a closed box. It is recommended to design so that all welding is done on the outside of the part. ④ Steel used in corrosive environments needs to consider anti-corrosion protection, such as choosing galvanized or alloyed galvanized metal with a protective zinc coating.

4.How can I reduce costs in sheet metal fabrication?

Through reasonable selection of materials, optimization of production process, improvement of production efficiency, reasonable arrangement of production plans and control of equipment maintenance costs, etc.,sheet metal fabrication costs can be effectively reduced.

Summary

Key design and engineering considerations in sheet metal fabricationcover everything from material selection to machining, from strength design to detailing. Only by taking these factors into account can the efficient, economical and reliable manufacture of sheet metal parts be achieved. Sheet metal designers and engineers should continue to learn and master new technologies and processes to respond to changing market needs and customer requirements.

Disclaimer

The content on this page is for reference only.Longshengdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

Longsheng Team

This article was written by multiple Longsheng contributors. Longsheng is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.