When we travel around the world of various commodities, from electronic devices in our hands to sneakers under our feet, from tableware in the kitchen to stationery in the office, it is not difficult to find that the outstanding performance of these products in design, functionality and beauty are often inseparable from the bags. Contribution of overmolding technology. Today, the LS team will lead you to delve into this topic, revealing the inner mechanism ofovermolding technologyand how it plays an irreplaceable role in multiple industries.

What is overmolding?

Overmolding is a production processthat focuses on combining soft thermoplastic elastomers or similar materials with rigid plastic or other substrate materials through injection molding or wrapping to create a composite structure with specific functional properties and aesthetic appearance. This process is widely used to improve the feel, anti-slip effect, visual beauty of products, and enhance product durability and ergonomic design.

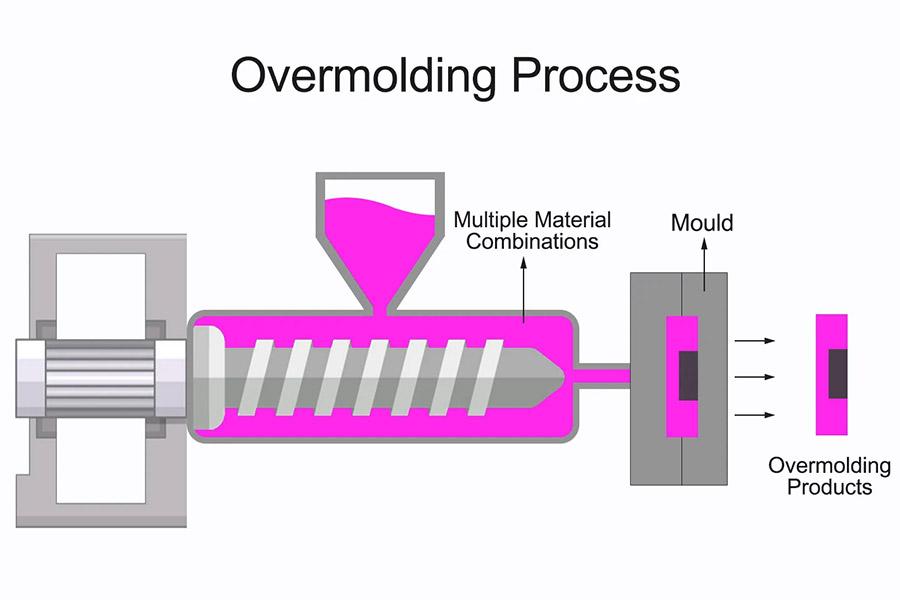

How Does overmolding work?

Overmolding is a manufacturing process in which specific materials are coated on the surface of a substrate to form a final product. Here’s a step-by-step overview of how it works:

Step 1: Prepare the substrate

Choose a suitable substrate, such as metal, plastic or other materials, and ensure that its quality meets production requirements. Place the substrate into the overmolding mold, ensuring that the position of the substrate is accurate for subsequent material injection and coating.

Step 2: Inject the first material

In some overmolding processes, it may be necessary to inject a first material as the core of the product. This material can be plastic, metal, etc., the specific choice depends on the design and performance requirements of the product. After the material is injected, it undergoes the necessary cooling and shaping to ensure it solidifies and reaches the desired shape and size.

Step 3: Pre-processing

For some substrates, such as plastic parts, cleaning may be required to remove impurities such as oil, dust and other impurities from the surface. Pre-treatment improves the adhesion between the cladding material and the substrate and ensures the quality of the final product.

Step 4: Insert the molded base into the overmolding tool

The core component (or pre-treated substrate) that has been cooled and cured is transferred to the overmolding tool. Ensure that the part is positioned accurately in the tool for subsequent injection of cladding material.

Step 5: Inject the overmolding materia

Choose suitable cladding materials, such as rubber, silicone, TPE, etc., which have good flexibility and abrasion resistance. The cladding material is injected into the cladding tool so that it fits snugly to the surface of the substrate. In this process, a chemical or mechanical bond occurs between the new material and the substrate to form a strong cladding.

Step 6: Cooling and ejection

Allow the overmolded part to cool and solidify in the mold. The cooling time depends on the type and thickness of the material. After the cooling is complete, the newly formed part is ejected from the mold using an ejection mechanism. Check the surface quality and dimensional accuracy of the component to ensure that it meets the design requirements.

What types of materials are used in overmolding?

The choice of materials used in overmoldingis very wide, depending on factors such as the performance, cost, processability and environmental requirements of the desired product. Here are some common materials used in overmolding:

- Thermoplastic elastomers (TPEs):have excellent slip resistance and elastic touch, adjust hardness and physical properties. It is often used in handles, grips, electronics, etc., to enhance the tactile and grip of the product.

- Thermoplastic polyurethane (TPU):divided into polyester type and polyether type, it has the characteristics of oil resistance, wear resistance, good mechanical strength, fatigue resistance, corrosion resistance, and good resilience. At the same time, TPU is fashionable and environmentally friendly and can replace PVC. It is suitable for the wrapping of strips, threads and strips, such as pet belts, motor car handle straps, trailer straps, etc. It is also commonly used for the coating of luggage products and metal lines.

- Polyurethane (PU):It has excellent toughness, strong tear resistance, and super wear resistance. It is widely used in light industry, chemical industry, electronics, textile, medical, construction, automobile, national defense and other fields. In the paper industry, the new PU lagging roller can be used to replace rubber materials under high temperature and high line pressure conditions.

- Silicone:Silicone powder is classified by the amount of siloxane content, and the intermolecular force of siloxane is strong, and it is not easy to disperse uniformly by physical methods. Silicones are lubricating, wear-resistant, and can improve the compatibility of the interface between non-polar inorganic minerals and organic compounds. Silicone masterbatches can be used as flow promoters, anti-caking agents, synergistic flame retardants, lubricants, hydrophobic agents, release agents, etc. in plastic processing.

- Polyethylene (PE):good water and moisture resistance, good chemical stability, certain mechanical tensile and tear strength, good flexibility, good low temperature resistance, but poor high temperature resistance. It is often used in plastic bags and as a packaging material for composite bags. Films made of high-pressure low-density polyethylene (LDPE) can be used to package foods with low requirements, especially dry foods with moisture barrier requirements.

- Polypropylene (PP):high melting point, low price, small specific gravity, excellent mechanical properties, outstanding stress crack resistance and wear resistance, good chemical stability, easy molding processing. It is widely used in chemical, electrical, automobile, construction, packaging and other industries. Plastic films used in flexible packaging of goods, also used as a heat sealing layer for composite materials.

- Acrylonitrile butadiene styrene (ABS): is a thermoplastic with high strength, impact resistance, and heat resistance. It can be used for overmolding with specific requirements, such as parts that require high strength and heat resistance.

- Polycarbonate (PC):It has the characteristics of high transparency, high impact strength, and high thermal stability. In overmolding, PC can be used for parts that require high transparency and high impact strength.

- Nylon:Excellent abrasion resistance, impact resistance and self-lubrication. It is often used in the manufacture of components that need to withstand high loads and wear, such as gears, bearings, etc. In overmolding, nylon can be used for components that require wear resistance and self-lubrication.

What are the common applications of overmolding?

As an advanced manufacturing process, overmolding has shown a wide range of application potential and great commercial value in many fields. Here's a breakdown of common applications for overmolding:

1. Consumer electronics

- Smartphones:Through overmolding technology, it can provide a soft touch to the shell of a smartphone, while increasing anti-slip performance and improving the user's experience.

- Headphones:Overmolding is often used in the earbuds to provide a comfortable fit and good sound isolation.

- Remote control:The key part of the remote control adopts overmolding technology, which can increase the softness and touch of the button, and improve the convenience of user operation.

- Charger:The housing and plug parts of the charger can be overmolded to improve durability and non-slip performance.

2. Auto parts

- Shift knob:The overmolding technology can make the shift knob have a better grip and anti-slip performance, and improve the safety of driving.

- Instrument panel:With overmolding technology, it is possible to provide a soft-touch feel to the dashboard while increasing aesthetics and durability.

- Handle covers:Automotive door handle covers and other components use overmolding technology to provide a comfortable grip and non-slip performance while increasing aesthetics.

3. Medical equipment

- Surgical instruments: The handle part of the surgical instrument adopts overmolding technology, which can increase comfort and anti-slip performance, and improve the accuracy and safety of the doctor's operation.

- Handle grips: Handle grips and other components in medical devices can provide a soft touch through overmolding technology, reducing fatigue for healthcare workers.

- Patient contact areas: The areas that come into contact with patients in medical devices are overmolded to increase comfort and reduce patient discomfort.

4. Hand tools

- Tool handle:The handle part of the hand tool adopts overmolding technology, which can provide a comfortable grip and non-slip performance, and improve the efficiency and safety of the tool.

- Grip:The grip section of a variety of hand tools can be overmolded to provide an ergonomic design that improves user comfort and operational efficiency.

Overmolding vs Insert Molding

Insert molding and overmolding are both effective ways to produce multi-material products without adhesives, streamlining the production process, reducing secondary assembly steps, and improving the quality of the final product. However, there are significant differences between the two molding technologies, which are manifested in the following aspects:

Insert Molding vs. Overmolding: Cost

- Insert Molding:Tooling costs are relatively low because traditional single-shot molding machines are typically used. Material costs depend on insert and resin material selection. The overall cost may be increased by the preparation of the insert and the set-up of the positioning device.

- Overmolding:Mold costs can be higher because of the complex mold structure required to accommodate the base and overmolding materials. Material costs depend on substrate and cladding material selection. The overall cost may increase due to pre-treatment of the cladding material, setup of the injection channels, and post-processing operations.

Insert Molding vs. Overmolding: Speed

- Insert Molding:Relatively fast production because traditional injection molding machines can be used for production. Pre-processing and positioning of inserts may slightly increase production time.

- Overmolding:Production can be slower because additional time is required for the injection and curing of the overmolding material. Complex mold structures and post-processing operations may also increase production time.

Insert Molding vs. Overmolding: Applications

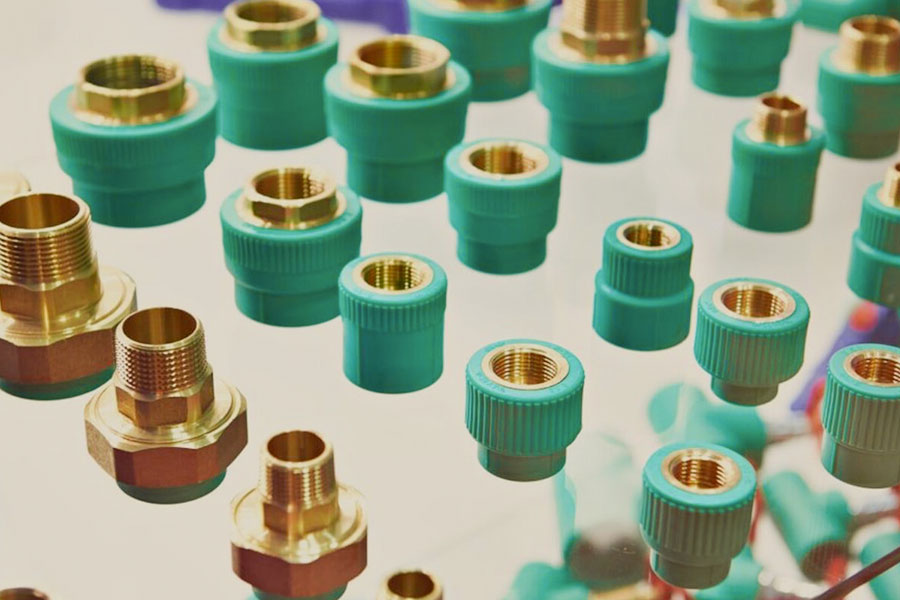

- Insert molding:often used to add a layer of plastic on top of a metal layer, such as making metal screwdrivers with plastic handles, or making insulation pipes, wires, etc. In addition, it is also widely used in electronic product packaging, medical device manufacturing and other fields.

- Overmolding:widely used to manufacture plastic parts with rubber handles, such as toothbrushes, mobile phone cases, etc. In addition, it is also suitable for making two-color plastic furniture, storage boxes, plastic containers, etc.

Insert molding vs. overmolding: Process Features and Advantages

Insert molding:①Features: The easy formability of resin and the rigidity, strength and heat resistance of metal complement each other and can be made into complex and exquisite metal-plastic integrated products. ②Advantages: A variety of materials can be combined to improve the overall performance and functionality of the product; it simplifies the product assembly process and reduces production costs.

Overmolding:①Features: The plastic profile is deformed by heating and external force, and then cooled and shaped to obtain the product. ②Advantages: Allows for relatively easy manufacturing of products containing multiple materials and/or colors; reduces assembly requirements for products, resulting in a more robust and durable overall design; suitable for large-scale production and/or products with multiple colors and multi-layer designs .

What are the design considerations for overmolding?

When designing an overmolded product, multiple factors such as material compatibility, mold design, part geometry and cycle time need to be considered.

1.Material compatibility:

- Adhesion of the substrate to the overmolding material: Ensuring good adhesion between the substrate and the overmolding material is critical. This often involves a deep understanding of the chemical and physical properties of the two materials to ensure they will bond together strongly.

- Material selection: When selecting base materials and coating materials, their thermal expansion coefficients, surface energy, wettability and other parameters should be considered to ensure that a good bonding interface can be formed during the molding process.

2. Mold design:

- Adaptation to the base part: The mold design must be able to accommodate and hold the base part while ensuring that the cladding material is evenly covered over the base part.

- Gate and vent design: Proper gate and vent design is critical for overmolding. The gate should be located in a location that is easy to remove and does not affect the appearance of the product, and the exhaust system should be able to effectively remove the gas from the mold to avoid air bubbles and defects.

- Mold material: Select the appropriate mold material according to the characteristics of the overmolding material and the molding temperature. For example, for high-temperature forming materials, tool steels that can withstand high temperatures should be selected.

3. Geometry of the part:

- About the draft angle:We need to design a suitable angle to ensure that the molded part can be easily taken out of the mold. For castings of different shapes and sizes, the draft angle that needs to be used for demoulding is also different. The draft angle of the mold is determined by the shrinkage of the cladding material and the friction coefficient of the mold.

- Undercut:Try to avoid undercutting designs on parts, as this can increase the complexity of demoulding. In order to ensure that no side slippage occurs, a simple mechanism can be used to prevent the workpiece from coming out of the mold cavity, i.e. by changing the gap between the slide and the die to ensure that the product dimensions remain stable and unchanged. In cases where undercuts need to be designed, sliders or other complex mold designs should be considered to ensure smooth mold emoulding.

- Parts assembly:When designing an overmolded part, careful consideration should be given to the assembly dependencies between the part and other types of parts. For example, an enclosure can be designed into two or more components. It is important to ensure that the enveloping area does not interfere with the assembly process, while also providing sufficient assembly clearance and precise positioning characteristics.

4. Cycle length:

- Additional steps:In the overmolding process, some additional operations are usually required, such as the pre-treatment of the substrate, the injection of the coating material, and the curing steps. There may also be additional steps such as heat treatment, chemical impregnation or conformal coating. These steps will result in an increase in the molding cycle time.

- Process optimization:In order to reduce the production cycle, we can consider adjusting and optimizing the process parameters of molding, such as the speed of injection, pressure, and temperature of the mold. Through these measures, the quality of products can be improved. In addition, we can also think about adopting more efficient molding tools and mold designs to shorten production cycles.

FAQs

1.How is overmolding done?

Overmolding is a molding process in which one material (usually plastic or rubber) is placed over the surface of another material (the base component). This process can be achieved through a variety of methods, including but not limited to: ① Two-color injection: On a two-color injection machine, one material is first injected into the mold to form a basic component, and then transferred to the corresponding cavity of another injection cylinder. Another material is injected into the component to form an integrated dual-material product. ②Two-step injection molding: Form a part of one of the materials on an injection machine, then put this part into another mold as an insert, and then inject the second material.

2.How does insert molding work?

Insert molding is a molding method that installs pre-prepared inserts of different materials into the injection mold and then injects resin. The molten material joins and solidifies with the insert to form an integrated product. The main steps include: ① Prepare inserts: Inserts can be made of metal, cloth, paper, wires, plastics, glass, wood and other materials. Select the appropriate insert according to product needs. ② Place the insert: Place the insert in the predetermined position of the injection mold. ③Injecting resin: Inject molten resin into the mold, and the resin will flow around the insert and fill the mold. ④Curing: The resin cools and solidifies in the mold, forming a strong bond with the insert.

3.What is the process of rubber overmolding?

Rubber overmolding is a process in which rubber materials are covered on the surface of other materials (such as metal, plastic, etc.). The general steps are: first clean and degrease to ensure that the surface of the workpiece is clean and free of oil or other impurities. Then the mold is designed and made according to the overmolding needs. The rubber material is then placed into the mold and pressure is applied to the workpiece to form a tight-fitting coating. Next, under a certain temperature and pressure, the preform is heated to cause the rubber material to undergo a vulcanization reaction, thereby solidifying into a stable rubber coating. Finally, the workpiece is removed and necessary cleaning and quality inspection is performed before packaging.

4.What materials are commonly used for overmolding?

Materials commonly used for overmolding include plastic materials such as thermoplastic elastomers (TPE), thermoplastic polyurethanes (TPU), polyurethanes (PU), silicones, polyethylene (PE), polypropylene (PP), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and metal materials or other special materials that may be used in some special cases. The choice of these materials depends on the specific application scenario, the required physical and chemical properties, and cost factors.

Summary

As an advancedinjection molding process, overmolding achieves a close combination of two different materials by precisely controlling the injection molding and fusion process of materials, providing strong technical support for the development of modern industry. With the continuous advancement of science and technology and the continuous improvement of technology, it is believed that overmolding technology will bring innovation and breakthroughs to more fields in the future.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.