The investment casting process is a time-honored manufacturing technique admired for its ability to produce high-precision components. Often referred to as lost wax casting, this method stands out for its unmatched ability to create intricate and complex geometric designs with excellent surface finishes. Companies across various industries have leveraged this process to benefit from the precision investment casting offers, making it a popular choice among investment casting manufacturers.

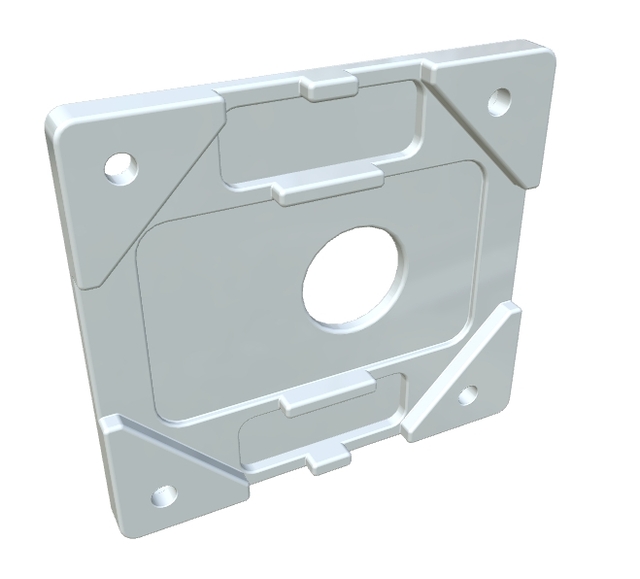

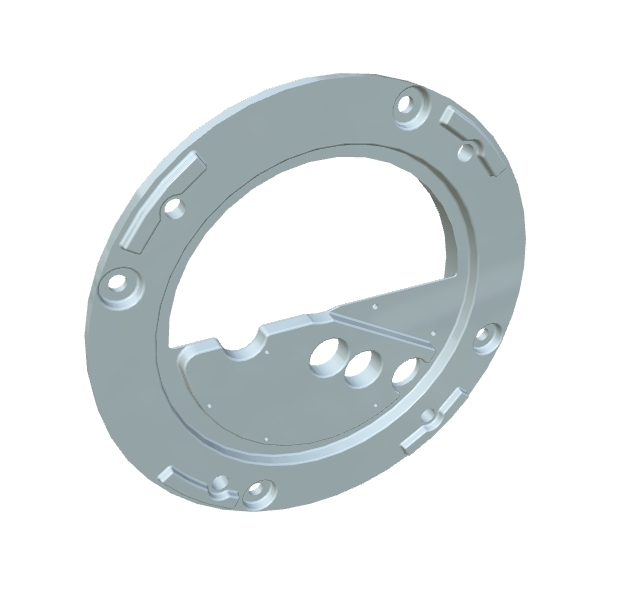

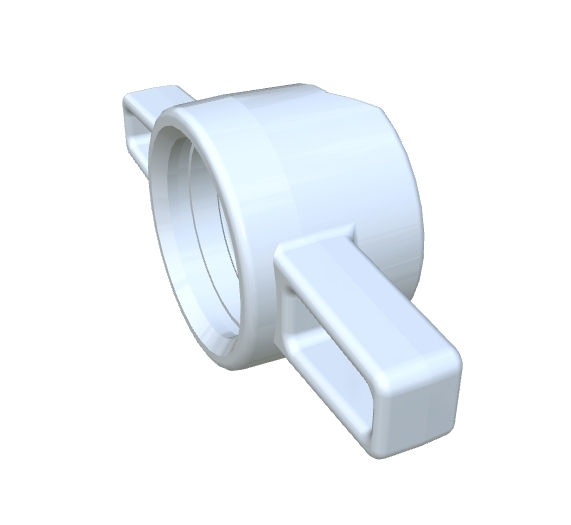

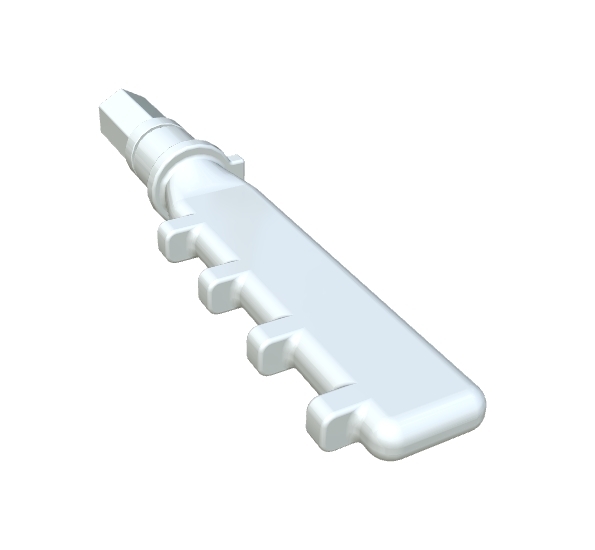

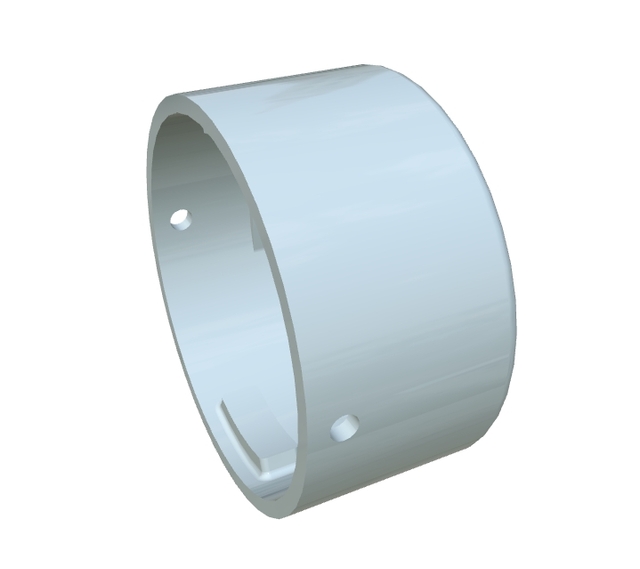

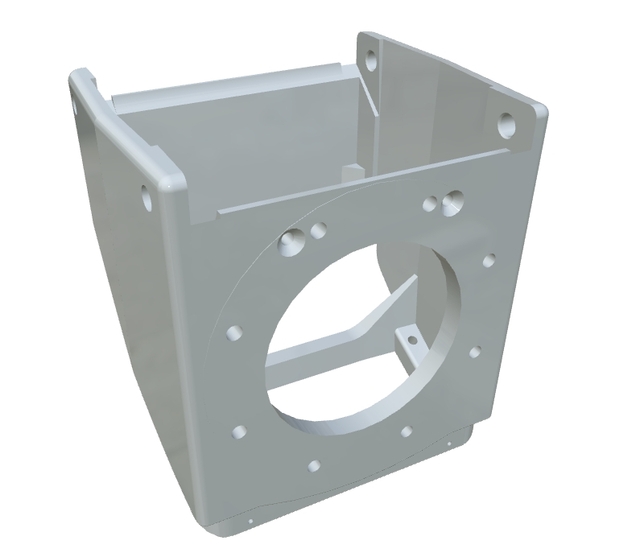

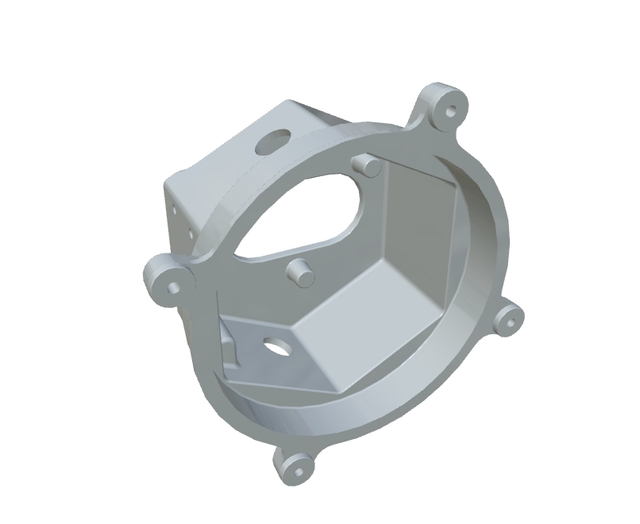

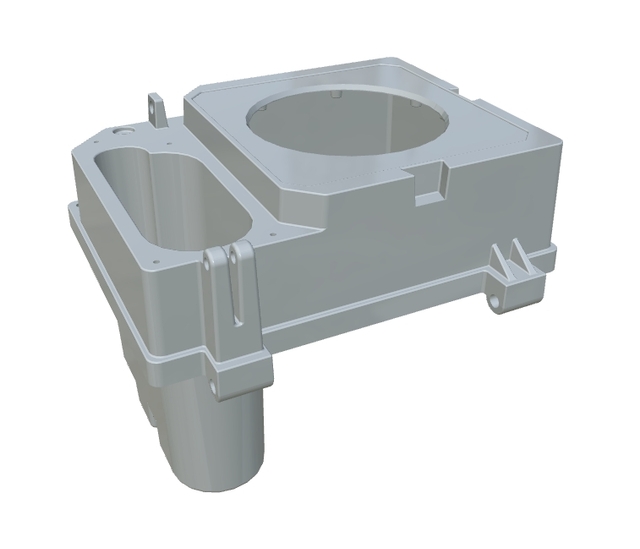

One of the major benefits of the investment casting process is the precision it provides. Whether utilized for consumer products or industrial components, investment casting ensures that each piece meets exact specifications. The metal housing bracket is a prime example of this precision. Designed with a sleek, circular design, this component serves as an essential part of mechanical assemblies. Its smooth, polished finish, achieved through investment casting, not only enhances its aesthetic appeal but also contributes substantially to its durability and resistance to environmental factors.

Investment casting materials vary significantly, offering versatility in production and functionality. The choice of materials in investment casting further improves the product, providing tailored properties suited to specific applications. Moreover, the modern housing bracket showcases the potential of investment casting applications by accommodating the needs of engineers and designers who value efficiency and innovation. Its strategically placed mounting holes provide versatile installation options, ensuring a secure attachment to various surfaces and a reliable performance in demanding scenarios.

When comparing investment casting vs sand casting, the former holds a definitive edge in producing detailed components with precise specifications. Investment casting's capability to produce components like the metal housing bracket—a perfect fit for enclosing motor parts or facilitating joint connections—demonstrates why it's preferred for projects that require high-quality finish and accuracy.

Overall, the investment casting process not only enhances flexibility and functionality in design but also uplifts the quality standards in manufacturing. Embracing this versatile and efficient process leads to superior products that cater to the diverse needs of modern engineering and industrial applications.

Understanding the Investment Casting Process and Its Advantages

احصل على أحدث الأسعار >

| Label | Value |

|---|---|

| ماركة | LS Custom Parts Manufactures |

| خدمة التخصيص | صب المعادن, صب الرمل, الصب تحت الضغط المنخفض, الصب تحت الضغط العالي, الاستثمار في الصب |

| تنسيق الرسم | 2D/(PDF/CAD) 、 3D (IGES/Step/GLB) |

| قدرات المواد | الألومنيوم 、 النحاس 、 البرونز 、 النحاس 、 المعادن الصلبة 、 المعادن الثمينة 、 الفولاذ المقاوم للصدأ 、 سبائك 、 tpr |

| عينة | حر |

| القدرة على التوريد | 100000 قطعة في اليوم |

| الانتهاء من السطح | التشطيب المخصص |

| سماكة | سمك مخصص |

| يكتب | التطرق/الحفر/النقش/الآلات الكيميائية/الآلات الليزر/الطحن/الدوران/الأسلاك EDM/النماذج الأولية السريعة/خدمات الآلات الأخرى |

| خدمات | تصنيع CNC ، صب المعادن ، صب الحقن ، تصنيع الصفائح المعدنية ، النماذج الأولية السريعة ، الطباعة ثلاثية الأبعاد |

الاتصال

هل أنت مستعد لبدء مشروعك التالي مع LS Manufacturing؟

اتصل بنا اليوم لمعرفة المزيد عن خدماتنا وكيف يمكننا مساعدتك في تحقيق أهدافك.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., Ltdمهل زمنية سريعة تبدأ من يوم عمل واحد فقط.

شهادة ISO 9001 وISO 14001 وIATF 16949 وAS9100D.

أكثر من 100 مادة متاحة، مع أكثر من 50 خيارًا لتشطيب الأسطح.

الإنتاج الضخم فعال من حيث التكلفة.

اطلب ما يصل إلى قطعة واحدة.