In the dynamic field of gear manufacturing, innovation has always been at the forefront of advancing industrial and technological solutions. One such breakthrough is the introduction of the Dual-Spline Precision Gear Hub—a marvel in mechanical engineering designed to excel in high-performance applications. Gear manufacturing encompasses techniques like gear cutting, gear grinding, and CNC gear machining, all essential for crafting components with precision and exactitude.

Gear manufacturing is an intricate process that leverages various production techniques to ensure each component meets stringent quality and performance criteria. Among these techniques, gear cutting and gear grinding are critical for achieving the desired accuracy and surface finish. With precision gear machining, manufacturers can produce gears that exhibit substantial efficiency and durability—an essential requirement for components such as the Dual-Spline Precision Gear Hub. This particular gear hub is crafted from high-grade alloy, providing exceptional longevity and resistance to wear, essential characteristics in demanding industrial environments.

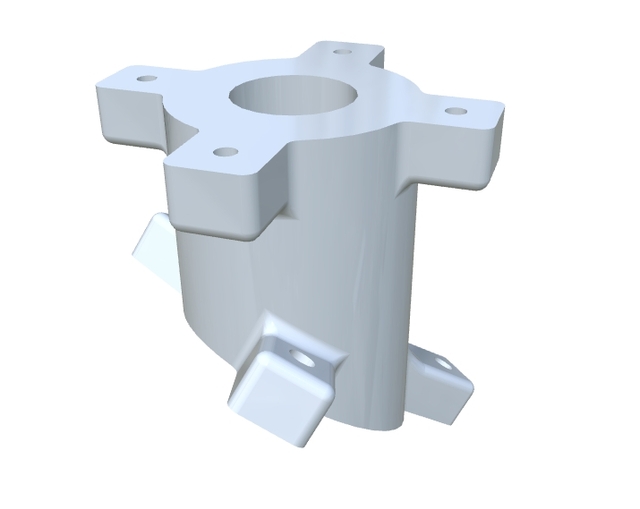

The uniqueness of the Dual-Spline Precision Gear Hub lies in its ingenious design. Featuring dual-splined shafts, the hub is engineered to optimize torque transfer, enhancing the overall efficiency of the machinery it's implemented in. Whether employed in industrial machinery or cutting-edge robotics, its robust cylindrical body assures durability and stability. The symmetrical teeth design allows for seamless integration with existing gear systems, facilitating easy assembly and maintenance.

Furthermore, the gear manufacturing process has evolved with technology, leading to innovations like CNC gear machining, which allows for mass production without sacrificing accuracy. Precision gear machining plays a crucial role in producing parts that meet the higher standards required in modern mechanical component design. Custom gear machining now makes it possible to address specific needs, which is particularly beneficial when upgrading machinery or developing new technological solutions.

In essence, the Dual-Spline Precision Gear Hub not only represents the pinnacle of gear manufacturing innovation but also sets a new benchmark in mechanical component design. With its combination of advanced material composition and meticulous engineering, this gear hub is poised to meet the highest standards of precision and reliability, contributing significantly to the advancement of industrial machinery and robotics.

Gear Manufacturing: Engineered for Precision & Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Gear Machining: Mastering Precision & Innovation Techniques

Revolutionize Gear Production with Gear Machining Services

Precision Gear Machining Services by LS Hardware Tech

Explore Top Gear Machining Services for Precision and Innovation

Gear Machining: Precision and Innovation in Manufacturing

Advanced Gear Machining Techniques for Enhanced Precision and Performance

Gear Machining Excellence: LS Hardware Tech<111>s Innovations

Advanced Gear Manufacturing: LS Hardware Tech Co., Ltd

Gear Machining Services: Precision and Efficiency Unveiled

Gear Machining Services: Precision & Custom Solutions