In the ever-evolving world of manufacturing, gear machining services play a crucial role in producing high-quality components that power machinery across various industries. LS Hardware Tech Co., Ltd, a leader in the field, specializes in providing cutting-edge gear machining solutions, including CNC gear machining, precision gear machining, and custom gear manufacturing. As technology advances, the demand for reliable, efficient, and precise gear machining services has risen exponentially.

At the heart of gear machining is the ability to produce gears with accurate dimensions and intricate details. With over 20 years of experience, LS Hardware Tech Co., Ltd has established itself as a trusted partner to major factories in China and around the world, serving industries like automotive, medical devices, consumer electronics, aerospace, and industrial equipment. The company's factory, equipped with over 100 high-end machining centers, offers high production efficiency, ensuring that clients receive top-quality products.

CNC gear machining is a key aspect of LS Hardware Tech Co., Ltd's offerings. This modern technique allows for the creation of intricate gear designs with unmatched precision. By utilizing CNC technology, the company can produce a wide range of gears, from prototypes to mass production, tailored to the specific needs of their clients. This flexibility and capability to handle diverse requirements make LS a go-to company for all gear manufacturing needs.

Precision gear machining is another significant service provided by LS Hardware Tech Co., Ltd. Precision is vital in ensuring the smooth operation of machinery, and the company has made substantial investments in state-of-the-art equipment to guarantee this level of accuracy. With precision gear fabrication, LS ensures that every gear meets stringent quality standards, providing stability and durability for a variety of applications.

Moreover, the company excels in custom gear machining, catering to unique industrial applications that require specialized solutions. Whether the need is for specialized materials, unique size dimensions, or complex gear geometries, LS Hardware Tech Co., Ltd delivers with a focus on innovation and customer satisfaction. This commitment to customization ensures that every gear produced is suitable for its intended purpose and meets the rigorous demands of its application.

A key component in gear manufacturing is the use of advanced gear cutting techniques. LS Hardware Tech Co., Ltd employs cutting-edge methods, such as gear grinding and CNC gear machining, to produce gears with precise teeth profiles and optimal performance. These meticulous processes reduce wear and tear, increase efficiency, and enhance the lifespan of the machinery components.

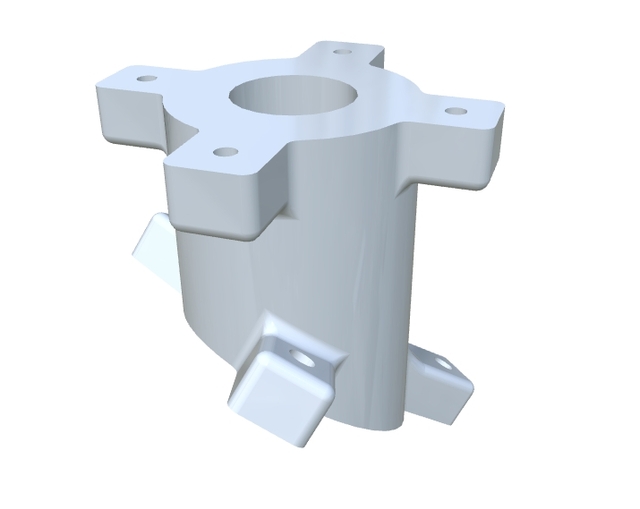

In addition to their exceptional gear machining services, the LS company is renowned for its production of high-precision hardware and plastic parts. Recently, they introduced a sleek and innovative product – the Wall-Mounting Bracket. This bracket is a perfect blend of form and functionality, crafted from high-strength, lightweight material. Its design features clean, angular lines and a minimalistic aesthetic, providing a modern elegance that seamlessly fits into both home and office settings.

The Wall-Mounting Bracket is engineered for versatility and durability, featuring a robust, open-frame structure that allows for various mounting options and easy cable management. Its precision-cut notches and slots ensure a snug fit and effortless installation, offering a reliable solution for organizing tech setups or mounting a diverse range of objects.

Furthermore, LS Hardware Tech Co., Ltd is ISO 9001:2015 certified, reflecting their commitment to quality and consistency. Their mission is to deliver innovative manufacturing solutions that empower clients to bring their ideas to life. They aim to be at the forefront of technology, continually improving their processes and capabilities to meet the evolving needs of their customers.

In summary, gear machining services have become indispensable in the manufacturing industry, and LS Hardware Tech Co., Ltd remains a pioneer in this field. Through their expertise in CNC gear machining, precision gear machining, custom gear solutions, and state-of-the-art gear cutting techniques, they ensure that every gear meets the highest standards of quality. Whether for mainstream manufacturing needs or specialized applications, LS Hardware Tech Co., Ltd provides exceptional solutions that drive efficiency, performance, and innovation.

Gear Machining Services: Precision, Custom, and CNC Solutions

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

Dongguan City Longsheng Hardware Technology Co., Ltd

Dongguan City Longsheng Hardware Technology Co., LtdPeople who viewed this also viewed

Gear Machining: Mastering Precision & Innovation Techniques

Revolutionize Gear Production with Gear Machining Services

Precision Gear Machining Services by LS Hardware Tech

Explore Top Gear Machining Services for Precision and Innovation

Gear Machining: Precision and Innovation in Manufacturing

Advanced Gear Machining Techniques for Enhanced Precision and Performance

Gear Machining Excellence: LS Hardware Tech<111>s Innovations

Advanced Gear Manufacturing: LS Hardware Tech Co., Ltd

Gear Machining Services: Precision and Efficiency Unveiled

Gear Machining Services: Precision & Custom Solutions