In today's rapidly advancing technological landscape, CNC gear machining stands as a pivotal process in the realm of manufacturing high-precision components. At the heart of industries like aerospace and mechanical engineering, the importance of custom gear machining cannot be overstated. By employing sophisticated techniques and cutting-edge machinery, we have stepped up our gear manufacturing process to meet and exceed the rigorous demands of the modern market.

One of the hallmarks of efficient CNC gear machining is the ability to produce high precision gears with unparalleled accuracy. This process involves precision gear machining techniques to shape and refine gears that operate flawlessly under demanding conditions. Our gear machining services are tailored to deliver robustness and reliability, qualities crucial in aerospace applications where mechanical components must perform without fail. Moreover, the diversity of our gear cutting techniques ensures that we can cater to a broad spectrum of applications, from the most common to the highly specialized, confirming our commitment to versatility and quality.

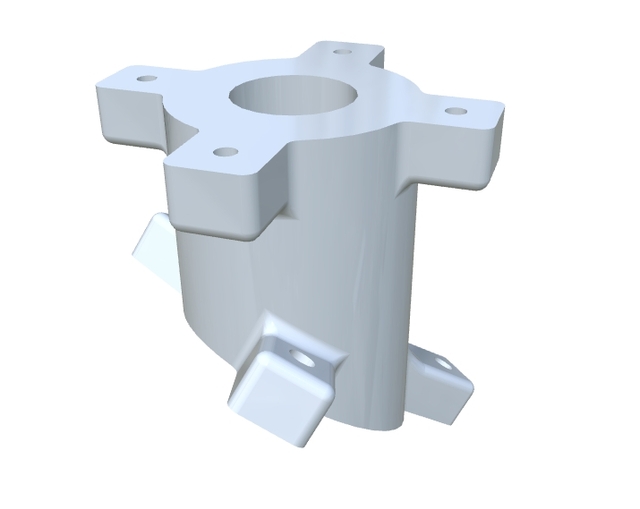

The introduction of our latest product, an intricately designed octagonal component, embodies our dedication to excellence. Crafted specifically for advanced mechanical and aerospace applications, this structural piece is a testament to our innovative approach. Engineered with precision cutouts and reinforcement features, it achieves an optimal balance between strength and lightweight efficiency. Such design intricacies allow for seamless integration into complex systems, resulting in enhanced performance and durability, even under extreme operational conditions. This product perfectly aligns with the needs of projects requiring the utmost precision, representing both superior engineering and practical application.

Innovation in gear manufacturing does not stop at the integration of high-grade materials and design enhancements; it thrives on adopting automated gear machining processes. By automating key aspects of gear machining, we can ensure consistent quality and precision, escalating the overall manufacturing efficiency. This not only shortens lead times but also cuts down on potential errors, affirming our position as leaders in gear machining services. With each component we produce, the goal is to push the boundaries of what is possible, delivering products that stand the test of time and usage.

As we forge ahead, driven by technology and ingenuity, our focus remains clear: to provide products that resonate with high-caliber engineering standards and meet the complex demands of modern industries. Whether it be through custom gear machining or exploring new gear cutting techniques, we are committed to evolving alongside the needs of our clients, ensuring that they receive not just a component, but a piece of technological craftsmanship.

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.