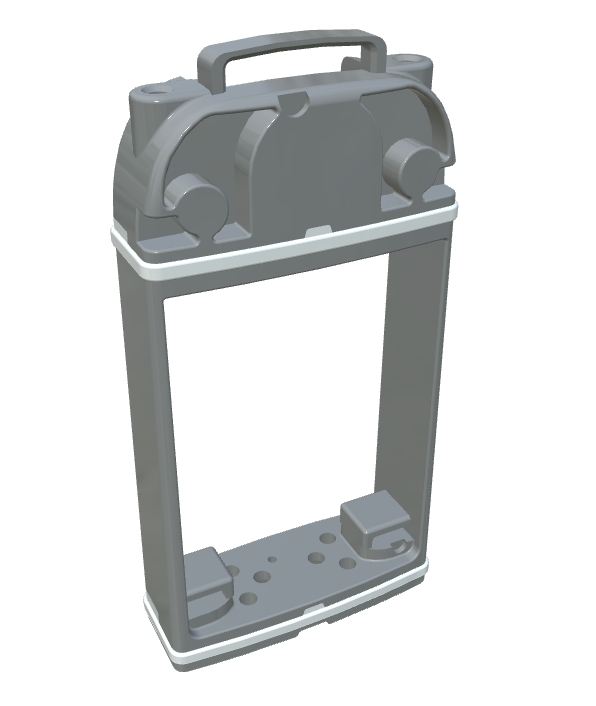

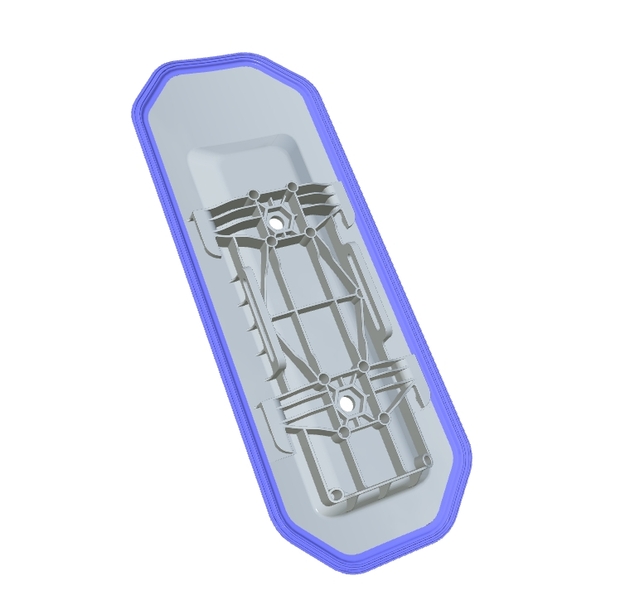

The innovative world of manufacturing and product design has introduced a technique known as the **overmolding process**. This method of using two or more materials in a single mold cycle is helping to create increasingly complex, functional products. Often employed in the creation of overmolded products, this process blends art and science to produce items with improved performance characteristics.

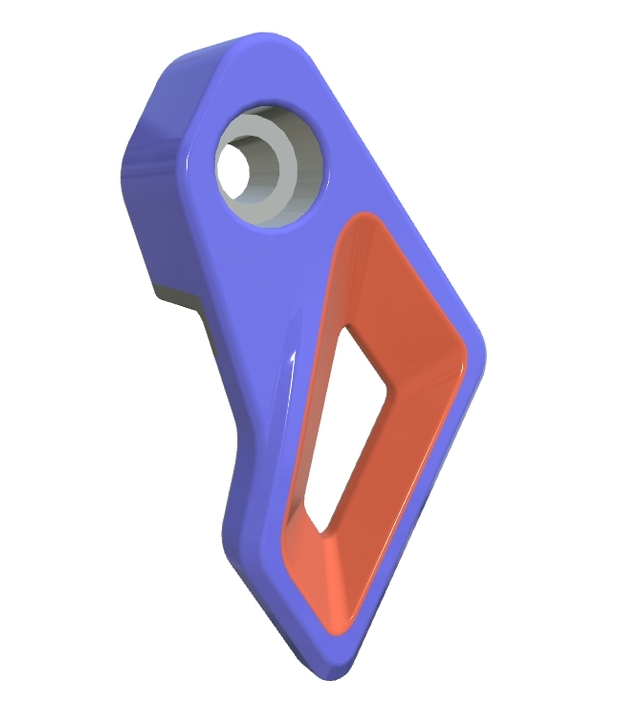

Overmolding techniques differ depending on the desired product outcome and the materials used. Thermoplastic overmolding, for example, is particularly popular due to its ability to enhance product resilience and longevity. Thermoplastics such as polycarbonate, nylon, and polypropylene are frequently used because of their durability and flexibility. These materials complement the primary substrate by offering additional sealing, grip, or aesthetic benefits, making them ideal for custom overmolding projects.

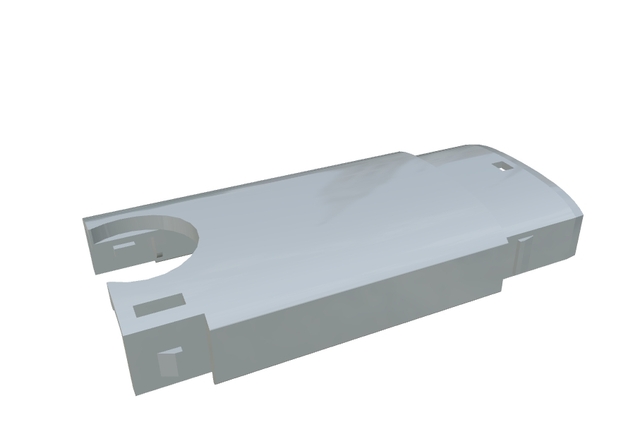

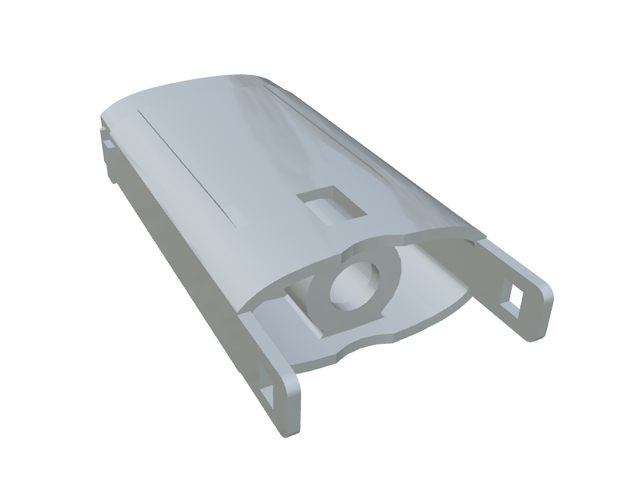

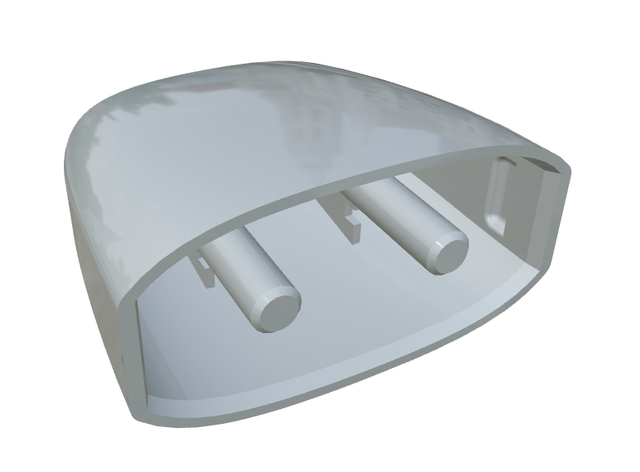

One of the many benefits of overmolding is its ability to combine materials in a way that traditional manufacturing methods can't, leading to ergonomic designs with added functionality. In products like the avant-garde Aluminum Profile Channel for LED Strip Lights, the incorporation of overmolding design attributes can contribute to superior performance. By ensuring optimized heat dissipation, such profiles maintain the longevity and efficiency of LED setups. This contemporary solution offers easy installations and robust fixture slots, permitting seamless and aesthetic integration into any setting, whether residential or commercial.

Aside from its technical advantages, overmolding is also an excellent choice for product customization. Custom overmolding allows designers to produce components that meet specific requirements, be it for grip, feel, or color. By utilizing the right overmolding materials and techniques, manufacturers can create products tailored to consumer demands, enhancing user experience substantially.

The integration of the Aluminum Profile Channel into lighting projects exemplifies the use of advanced design without compromising functional precision. Its semi-arched cover diffuses LED light effectively, ensuring a steady stream of illumination while shielding it from dust and moisture—an ideal representation of comprehensive overmolding benefits.

In conclusion, the overmolding process offers an impressive range of possibilities. By understanding and applying the various overmolding techniques to create overmolded products, industries can deliver products that marry aesthetic appeal with unmatched performance. Whether it's enhancing thermoplastic overmolding materials or exploring new design integrations, the opportunities for innovation are vast, paving the way for a new era in product development.

Mastering the Overmolding Process for Enhanced Products

最新の価格を取得する >

| Label | Value |

|---|---|

| ブランド | LSカスタムパーツメーカー |

| カスタマイズサービス | 射出成形, プラスチック射出成形, プラスチック射出成形金型, インサート成形, オーバーモールド |

| 描画形式 | 2d/(pdf/cad)、3d(iges/step/glb) |

| 材料能力 | アルミニウム、真鍮、銅、銅、硬化金属、貴金属、ステンレス鋼、合金、TPR |

| サンプル | 無料 |

| 供給能力 | 1日あたり100000個 |

| 表面仕上げ | カスタマイズされた仕上げ |

| 厚さ | カスタマイズされた厚さ |

| タイプ | ブローチ/掘削/エッチング/化学機械加工/レーザー加工/ミリング/ターニング/ワイヤーEDM/ラピッドプロトタイピング/その他の機械加工サービス |

| サービス | CNCの機械加工、金属鋳造、射出成形、板金製造、迅速なプロトタイピング、3D印刷 |

お問い合わせ

LS Manufacturing で次のプロジェクトを開始する準備はできていますか?

当社のサービスの詳細と、お客様の目標達成をどのように支援できるかについては、今すぐお問い合わせください。

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., Ltdわずか 1 営業日から始まる迅速なリードタイム。

ISO 9001、ISO 14001、IATF 16949およびAS9100D認証。

100 を超える材料が利用可能で、50 以上の表面仕上げオプションがあります。

コスト効率の高い大量生産。

1個からご注文いただけます。