Welding safety is an essential aspect that all welders must understand to ensure a safe working environment. Whether you are working with arc welding, MIG welding, or TIG welding, the use of appropriate welding safety gear and practices cannot be overstated. Of significant importance is the proficiency in various welding techniques, which directly impacts the quality and safety of the work performed. The range of welding equipment available in the market today offers extensive options, but with each comes the responsibility of understanding how to safely operate them.

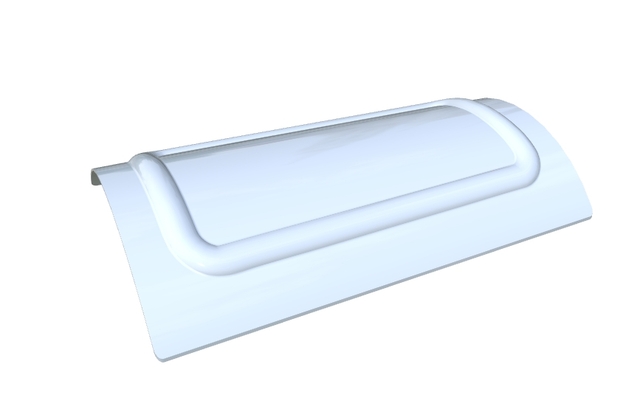

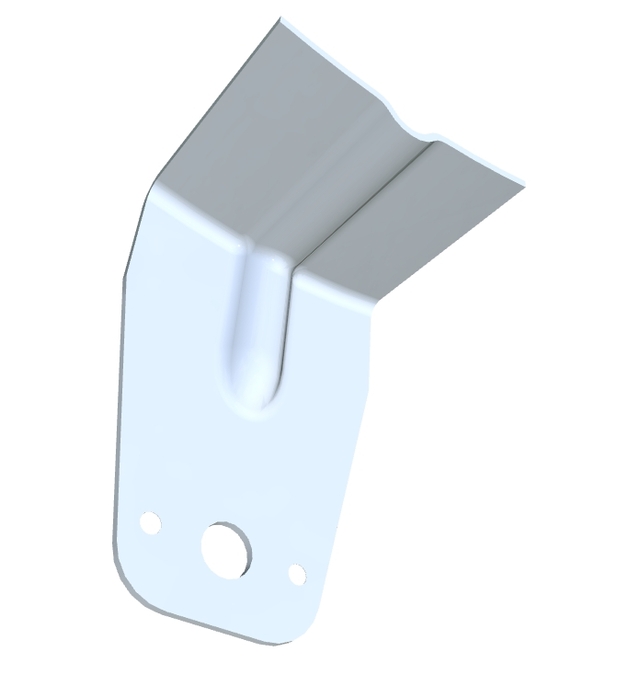

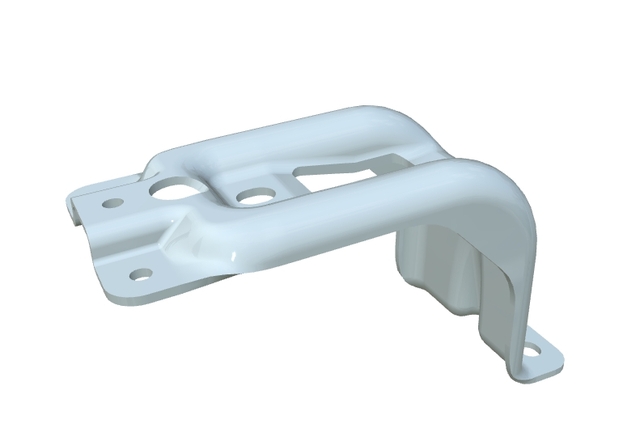

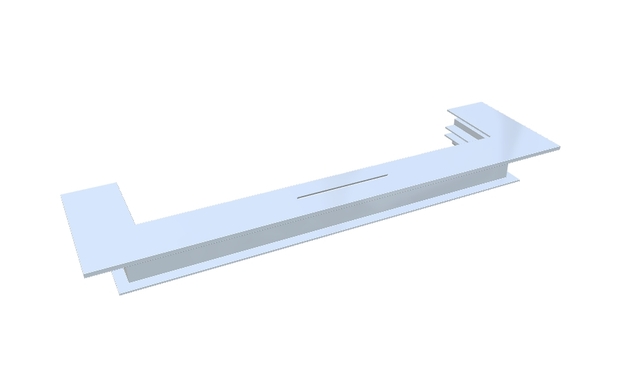

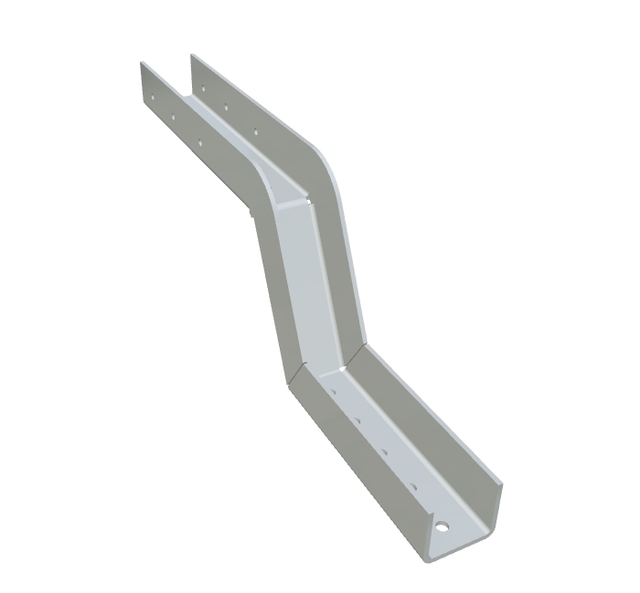

In the world of construction and DIY projects, the advent of innovative products has significantly reshaped approaches towards design and implementation. A prime example of such innovation is the groundbreaking metal bracket introduced by LS Hardware Tech Co., Ltd. This sleek and versatile product is not only a testament to refined engineering but also a perfect blend of aesthetic appeal and durability. LS Hardware Tech Co., Ltd, with its over 20 years of experience in manufacturing durable and high-quality hardware, has crafted this bracket with meticulous attention to detail.

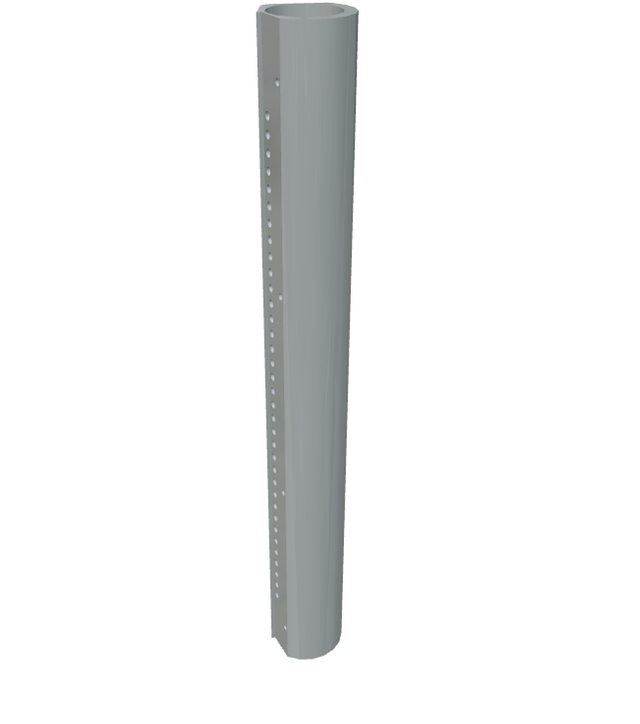

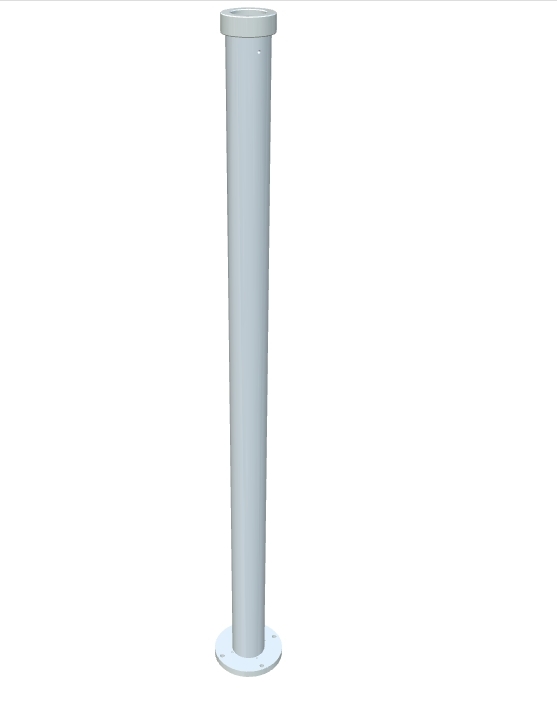

The metal bracket features a central hole along with two additional alignment holes, offering versatile fastening options. This design caters to different surface attachment requirements while maintaining structural integrity, and it enhances support with its bent form, making it ideal for structural reinforcement. LS Hardware Tech Co., Ltd aims to deliver on its mission to empower clients by melding sophistication with utility through products like this bracket. The company's pledge to innovation and customer satisfaction is rooted in their extensive experience and advanced manufacturing capabilities, which have seen them collaborate with major factories in China and serve more than 150 countries globally.

For aspiring professionals seeking expertise in the welding industry, obtaining welding certification and engaging in welding training are pivotal steps. With advancements in welding technologies and techniques, continuous learning is crucial. Whether you're operating at an industrial level or engaging in intricate DIY tasks, understanding the role of welding safety and choosing the right equipment is indispensable.

The ISO 9001:2015 certified LS company, founded by Mr. Nick Zhang, embodies excellence in manufacturing and innovation. Their high-end machining centers ensure that the products, including the revolutionary metal bracket, meet the highest standards of precision and quality. Through their products and exceptional service, LS Hardware Tech Co., Ltd continues to lead the way in meeting diverse manufacturing needs, from consumer electronics to aerospace components.

In conclusion, welding safety remains a core consideration across all spheres of welding-related activities. Whether you’re leveraging the latest welding equipment or integrating sophisticated hardware like LS's metal bracket into your projects, devotion to safety and precision is paramount. LS Hardware Tech Co., Ltd ensures you have the right tools with their cutting-edge products, all crafted to support you in creating robust, efficient, and aesthetically pleasing innovations.

Welding Safety: Ensuring Safe Welding Practices

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Sheet Metal Fabrication, Laser Cutting, Bending, Stamping, Welding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Mastering Welding Techniques for Industrial Excellence

Exploring Types of Welding: Techniques, Safety, and More

Welding Safety: Ensuring Safe Welding Practices

Mastering Welding Techniques: Types, Safety, and Equipment

Master Welding Techniques for Architectural Brackets

Mastering Welding Techniques: Elevate Your Projects

Mastering Welding Techniques for Modern Urban Safety

Mastering Welding Techniques: Weld Safely with Innovation