The world of gear manufacturing is both intricate and fascinating, offering a glimpse into the sophisticated processes that drive modern industry. With its numerous applications in essential sectors like automotive, aerospace, and industrial equipment, precision gear machining remains a critical aspect of the manufacturing landscape. At the heart of this complex field stands LS Hardware Tech Co., Ltd, a leader in delivering high-quality, customized solutions.

LS Hardware Tech Co., Ltd was founded by Mr. Nick Zhang along with a team of seasoned engineers, with a mission to provide innovative manufacturing solutions across the globe. With over 20 years in the industry, LS has risen to become a trusted name, known for its efficiency and high production standards. This ISO 9001:2015 certified company operates with over 100 state-of-the-art machining centers, allowing them to offer services ranging from prototypes to mass productions efficiently. Their expertise spans across industries such as automotive, medical devices, consumer electronics, aerospace, and more.

Understanding gear manufacturing starts with recognizing the variety of techniques involved, such as gear cutting techniques, gear grinding services, and gear hobbing machines. These methodologies ensure precision gear machining, necessary for maintaining the accuracy and efficacy of the components produced. Each technique plays an integral role in achieving the desired geometrical accuracy, surface finish, and strength that are crucial for modern applications. Companies like LS Hardware Tech have mastered these techniques thanks to their advanced CNC gear machining capabilities, enabling them to produce gears that meet stringent industry standards.

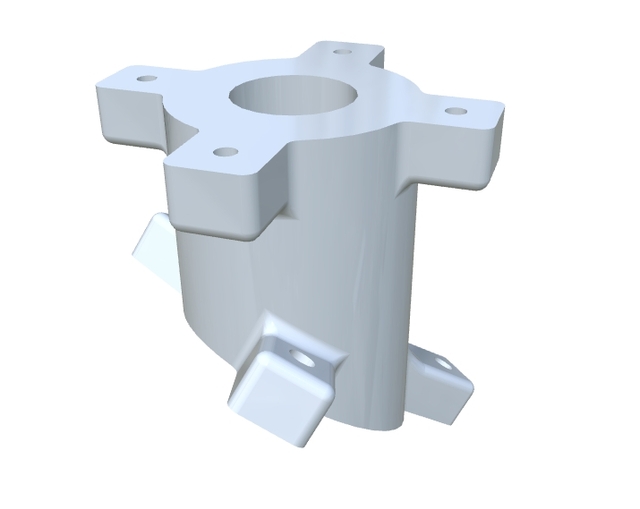

But LS Hardware Tech does not only excel in gear manufacturing. Their latest innovation, the Modular Wall Panel, showcases their versatility in offering practical and design-friendly solutions. Crafted from durable materials, this sleek panel features multiple cutouts that offer flexibility in application. Whether it's for integrating electrical components, ensuring efficient cable management, or blending in decorative elements, the Modular Wall Panel distinguishes itself with its minimalist aesthetic. This versatile solution not only complements any interior design but also extends design possibilities while maintaining a clean and effective workspace.

The highly customizable nature of LS Hardware Tech's products is facilitated by their usage of advanced gear design software and precision engineering tools. The innovative processes and technologies they employ are rooted in the company's commitment to staying at the forefront of the manufacturing industry. By continually improving their processes, LS ensures that their solutions are not just aligned with current market demands but also with future trends, empowering clients to transform ideas into reality.

LS Hardware Tech's impact is not just national but global, providing its cutting-edge solutions to over 150 countries and regions worldwide. Their modular and customized approaches provide significant benefits across various markets, reflecting their understanding of diverse customer needs. Their client-centric products are designed to align with different architectural styles and functionalities, demonstrating LS Hardware Tech's strategic vision in the competitive gear manufacturing industry.

In conclusion, the success of LS Hardware Tech Co., Ltd in gear manufacturing and related fields underlines their dedication to delivering superior solutions tailored to specific customer requirements. Their prowess in gear cutting, grinding, and precision machining, coupled with their versatile product offerings like the Modular Wall Panel, defines them as leaders in manufacturing excellence. Their extensive experience and profound commitment to innovation and customer satisfaction cements their reputation as a trusted partner in realizing the full potential of modern industrial design and production.

The Intricacies of Gear Manufacturing: Precision and Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Gear Machining: Mastering Precision & Innovation Techniques

Revolutionize Gear Production with Gear Machining Services

Precision Gear Machining Services by LS Hardware Tech

Explore Top Gear Machining Services for Precision and Innovation

Gear Machining: Precision and Innovation in Manufacturing

Advanced Gear Machining Techniques for Enhanced Precision and Performance

Gear Machining Excellence: LS Hardware Tech<111>s Innovations

Advanced Gear Manufacturing: LS Hardware Tech Co., Ltd

Gear Machining Services: Precision and Efficiency Unveiled

Gear Machining Services: Precision & Custom Solutions