In the world of precision mechanics, gear grinding is an essential process that ensures the smooth operation of machinery in various industries. Whether you're looking at high-speed automotive engines or intricate robotic assemblies, the significance of gear machining can't be overstated. Our latest offering, the HelioGear, is a testament to the advancements in gear grinding technology, promising exceptional performance and longevity.

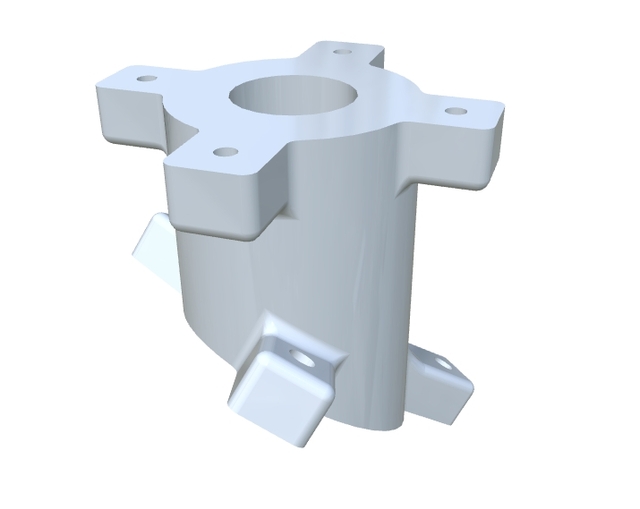

The HelioGear is a high-performance gear meticulously crafted to showcase superior efficiency and durability. At the heart of this innovation lies its expertly machined teeth, which ensure seamless interaction with complementary components. This makes it a perfect fit for critical applications in gear manufacturing, where precision is paramount. For those familiar with CNC gear machining, the HelioGear's central bore is perfectly calibrated for easy mounting, guaranteeing a snug fit and smooth operation.

Adding to the HelioGear's appeal is its sleek silver finish. This isn't just for aesthetic reasons; the finish provides a protective layer, effectively guarding against corrosion. Made from the finest-grade steel, the gear offers robust solutions for challenges posed by high torque and potential wear, typical in environments requiring custom gears. By choosing HelioGear, you're not just investing in a product; you're embracing a commitment to precision and innovation that sets the benchmark in the gear design industry.

Gear grinding techniques like gear shaping and gear hobbing are integral to creating such advanced components. By understanding these processes and utilizing the best gear materials, the HelioGear ensures optimum performance. This gear doesn't just facilitate gear assembly; it enhances it, setting a new standard in gearbox machining.

Lastly, in the broader spectrum of gear cutting and gear manufacturing, HelioGear emerges as a leader. If your project requires precision gear machining that excels in both functionality and design, HelioGear is the go-to choice. Elevate your machinery's operational potential with HelioGear, where every aspect of its design and function is tailored to push the boundaries of contemporary gear machining.

Revolutionizing Gear Grinding with HelioGear

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Gear Machining: Mastering Precision & Innovation Techniques

Revolutionize Gear Production with Gear Machining Services

Precision Gear Machining Services by LS Hardware Tech

Explore Top Gear Machining Services for Precision and Innovation

Gear Machining: Precision and Innovation in Manufacturing

Advanced Gear Machining Techniques for Enhanced Precision and Performance

Gear Machining Excellence: LS Hardware Tech<111>s Innovations

Advanced Gear Manufacturing: LS Hardware Tech Co., Ltd

Gear Machining Services: Precision and Efficiency Unveiled

Gear Machining Services: Precision & Custom Solutions