Progressive die stamping has revolutionized the way manufacturers produce complex metal parts. This technique, which is central to many modern manufacturing processes, is renowned for its efficiency, precision, and cost-effectiveness. Progressive die stamping is an automated die stamping method that employs a series of stamping dies to transform sheet metal into complex components in a single, continuous process. This sophisticated technique is widely used in industries ranging from automotive to consumer electronics, thanks to its ability to produce high-quality components with remarkable accuracy and minimal waste.

LS Hardware Tech Co., Ltd is a leader in the progressive stamping process. With a reputation that spans over 20 years, LS Hardware has established itself as a powerhouse in the hardware and plastic parts manufacturing industry. Founded by Nick Zhang and an experienced team of engineers, the company boasts a track record of delivering efficient solutions to more than 5,000 clients. The factory is ISO 9001:2015 certified and houses over 100 high-end machining centers, which contribute to its high production efficiency and superior quality products. LS Hardware specializes in high-precision stamping services which meet the full spectrum of industrial needs, from prototyping to mass production.

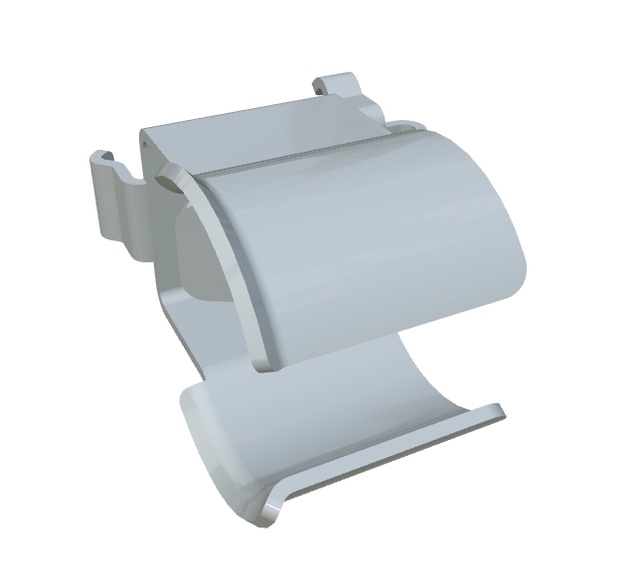

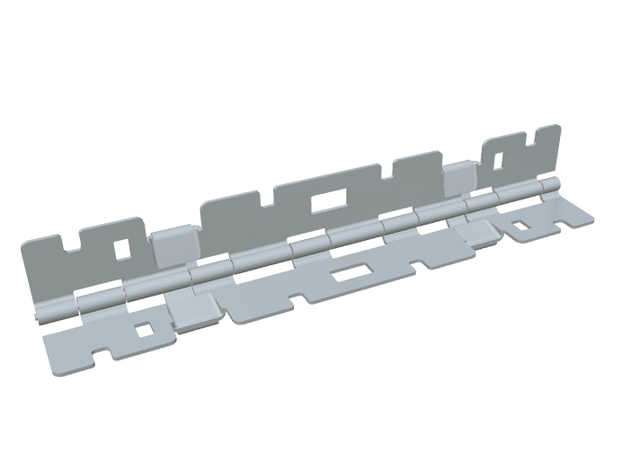

One of LS Hardware’s standout products is their continuous hinge, a testament to their expertise in stamping dies manufacturing and metal fabrication methods. This hinge is a sleek amalgamation of durability and versatility, built to integrate seamlessly into a multitude of applications. Its minimalist design ensures smooth and uninterrupted movement, enhancing the functionality of doors, panels, and cabinets. Crafted from high-quality material, this continuous hinge promises stability and resistance against wear and tear, making it an ideal choice for both industrial and residential settings. The continuous hinge not only satisfies functional requirements but also adds to modern design sensibilities with its aesthetic appeal.

The success of the progressive die design and metal fabrication techniques employed by LS Hardware is largely owed to their commitment to innovation and continuous process improvement. They consistently enhance their capabilities to cater to the evolving demands of diverse industries such as automotive, medical devices, aerospace, and industrial equipment—their services currently extend to over 150 countries and regions worldwide. The company’s dedication to delivering innovative manufacturing solutions allows clients to bring their visions to life, positioning LS Hardware at the cutting edge of technology.

Progressive die stamping, as demonstrated by LS Hardware Tech Co., Ltd, is not just about efficiency; it is about quality, precision, and the pursuit of excellence. By leveraging automated die stamping and high-precision stamping techniques, LS Hardware ensures that every component they produce meets the highest standards of quality and reliability. The continuous hinge is a prime example of how aesthetic design and functional efficiency can be united through progressive die stamping. As industries across the globe continue to seek high-quality, reliable components, the expertise and proven prowess of LS Hardware in progressive die stamping techniques make them a partner of choice in the manufacturing landscape.

Progressive Die Stamping: Precision Meets Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Blanking, Deep Draw Stamping, Hydroforming, Progressive Die Stamping, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.